- Joined

- Dec 10, 2007

- Messages

- 257

- Points

- 87

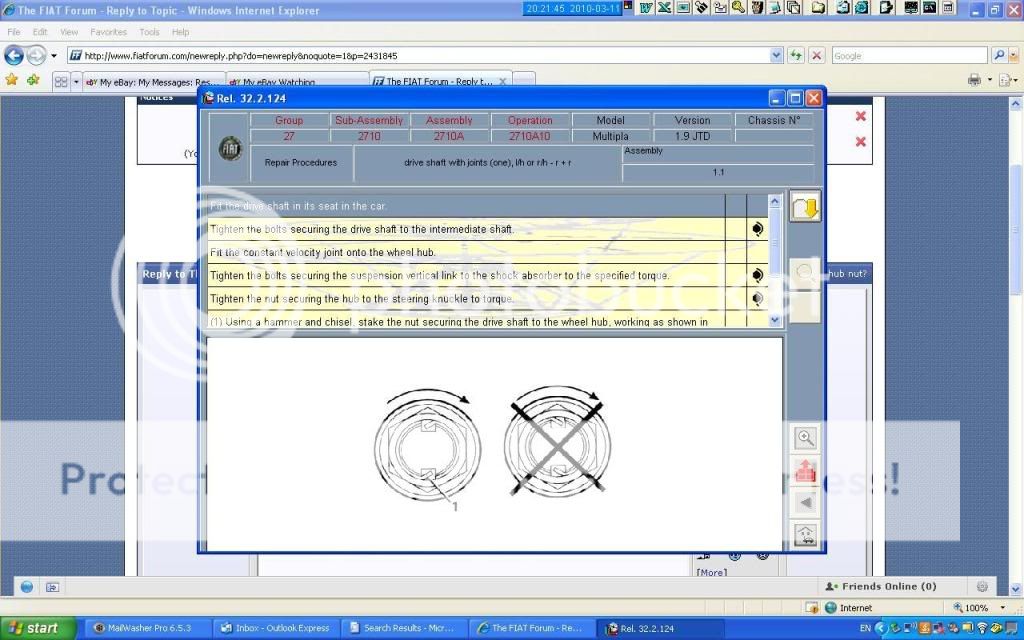

I have a new hub nut for my Multipla and have torqued to 70Nm + 62 degrees. The diagram shows how to stake the nut so that it doesn't unwind. The old nut had an L shape cut to allow a piece to be bent into the groove in the drive shaft. I couldn't re-use the old nut. The new nut has no cuts so what do people do?

Last edited: