Hi there,

New to the forum but have scanned a fair bit for advise on this matter as a guest. I'm having solenoid issues with my starter motor where sometimes motor spins but doesn't engage the flywheel, if i repeat if finally works after sometimes 1 or 10 tries! Í initially assumed faulty solenoid so i pulled it off gave everything a clean and still had issues.

I got lazy and bought a second hand starter motor to just swap out but this one doesn't even engage the solenoid át all. I tested both motors and solenoids with jumper cables to the battery and both actually work fine, (should of done this before buying another one..) so i assume the second one is maybe more sensitive to a low voltage trigger than the old one (it has a longer spring in the solenoid).

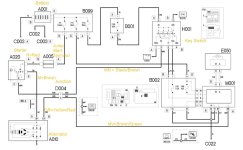

I grabbed a volt meter and tested the ignition wire and i get 12.4v when the cable is disconnected (grounding to starter case) however i only get around 10.5v when it is connected to the starter... I found the junction D004 and gave that a clean and also gave the earth strap contacts a clean although i'll replace the cable later this week just in case...

I also pulled the ignition switch apart and i noticed the voltage dropped to 11v on the 12v in pin (30) with ground to the bodywork when i turn the switch to ignition (not sure if that means anything..)

I also got 0.2 Ohms resistance for the ignition cable from the ignition switch to the connector for the starter which i assume is fine.

can any tell me anything else i can check?

I also gave the battery a charge overnight to ensure that wasn't an issue as the van has sat for a few weeks (issue was present before this)

worst case i was thinking maybe add another relay next to the starter that is triggered off the ignition switch wire to supply the 12v voltage from the battery connector on the solenoid to the ignition terminal on the solenoid... but would rather find the actual issue if possible.

New to the forum but have scanned a fair bit for advise on this matter as a guest. I'm having solenoid issues with my starter motor where sometimes motor spins but doesn't engage the flywheel, if i repeat if finally works after sometimes 1 or 10 tries! Í initially assumed faulty solenoid so i pulled it off gave everything a clean and still had issues.

I got lazy and bought a second hand starter motor to just swap out but this one doesn't even engage the solenoid át all. I tested both motors and solenoids with jumper cables to the battery and both actually work fine, (should of done this before buying another one..) so i assume the second one is maybe more sensitive to a low voltage trigger than the old one (it has a longer spring in the solenoid).

I grabbed a volt meter and tested the ignition wire and i get 12.4v when the cable is disconnected (grounding to starter case) however i only get around 10.5v when it is connected to the starter... I found the junction D004 and gave that a clean and also gave the earth strap contacts a clean although i'll replace the cable later this week just in case...

I also pulled the ignition switch apart and i noticed the voltage dropped to 11v on the 12v in pin (30) with ground to the bodywork when i turn the switch to ignition (not sure if that means anything..)

I also got 0.2 Ohms resistance for the ignition cable from the ignition switch to the connector for the starter which i assume is fine.

can any tell me anything else i can check?

I also gave the battery a charge overnight to ensure that wasn't an issue as the van has sat for a few weeks (issue was present before this)

worst case i was thinking maybe add another relay next to the starter that is triggered off the ignition switch wire to supply the 12v voltage from the battery connector on the solenoid to the ignition terminal on the solenoid... but would rather find the actual issue if possible.