This does not refer to earlier single EGR systems or to later AdBlu SCR engines.

Note this is a guide and not definative. It is up to you to make decissions. It is the result of my investigations of data from many contributors and discussion with many Fiat Forum members, its their work I’m just reporting it. As it would be totaly unfair to mention just one and not to acknowledge all contributors i wont mention FredAstaire.

Question :

My van has thrown a P0401 code should I change the HPEGR valve?

Answer :

No. Not before reading the rest of this page.

A number of people have changed the HPEGR valve on the basis that the code is listed as.

P0401 Exhaust Gas Recirculation Flow Insufficient Detected

There has been no resolution of the problem as a result of the change.

What should I do?

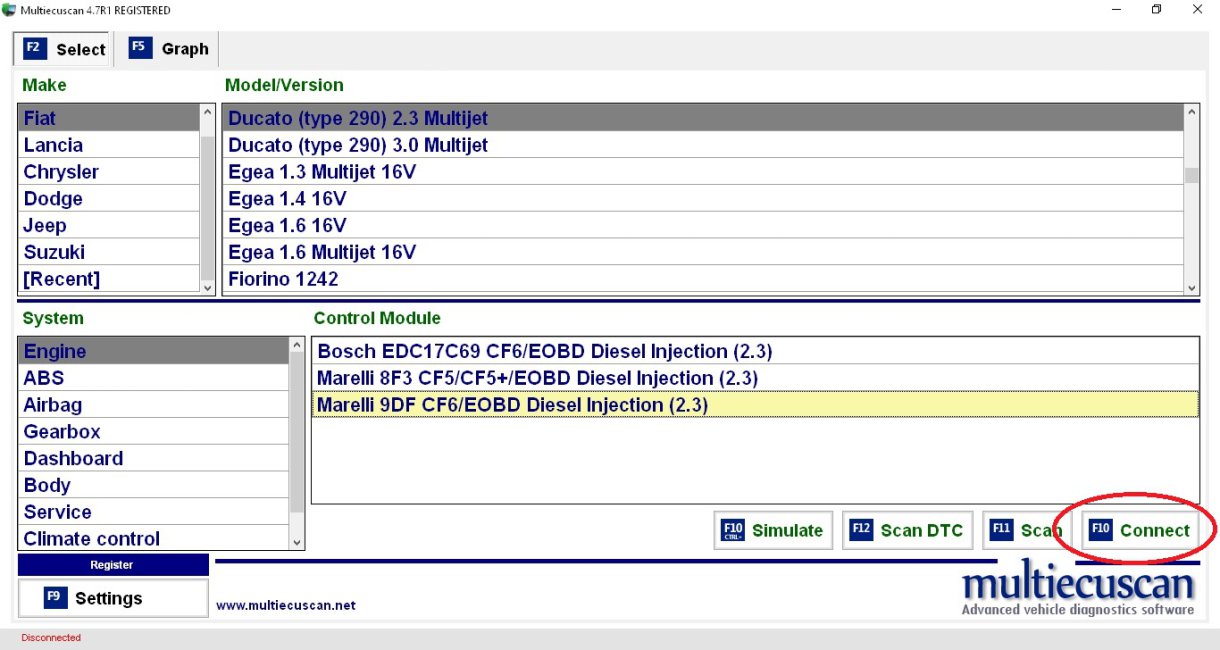

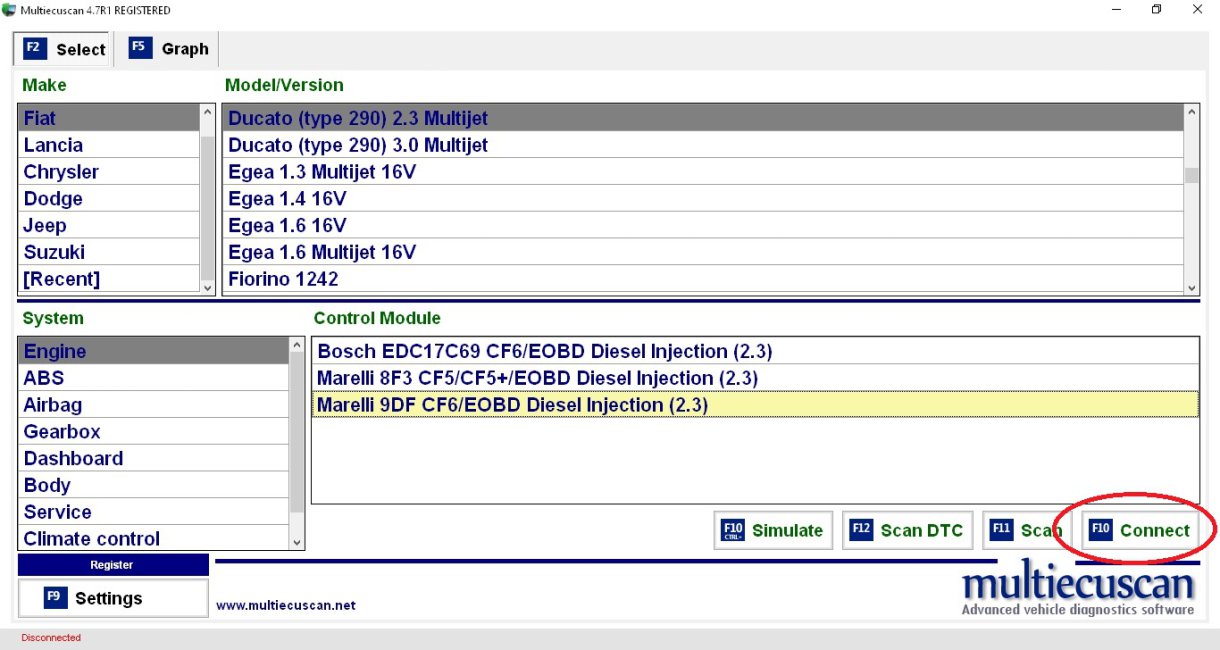

With Multiecuscan check the freeze frame data for the error.

With Multiecuscan set to graph the following parameters. See tutorial

www.fiatforum.com

Example Picture freeze Frame

www.fiatforum.com

Example Picture freeze Frame

Comparison of 401 Freeze frame data

5 different engines and 4 results from engine G.

Tables

Things to note:

1 Actual Air Intake % of Desired is typicaly 25% with one example at 33%

2 LPEGR is fully open

3 All engines are warming up (EGR exclusion valve off) but close to temperature not cold.

4 Throttle position very close 6 of 8 11.87% others within .2%

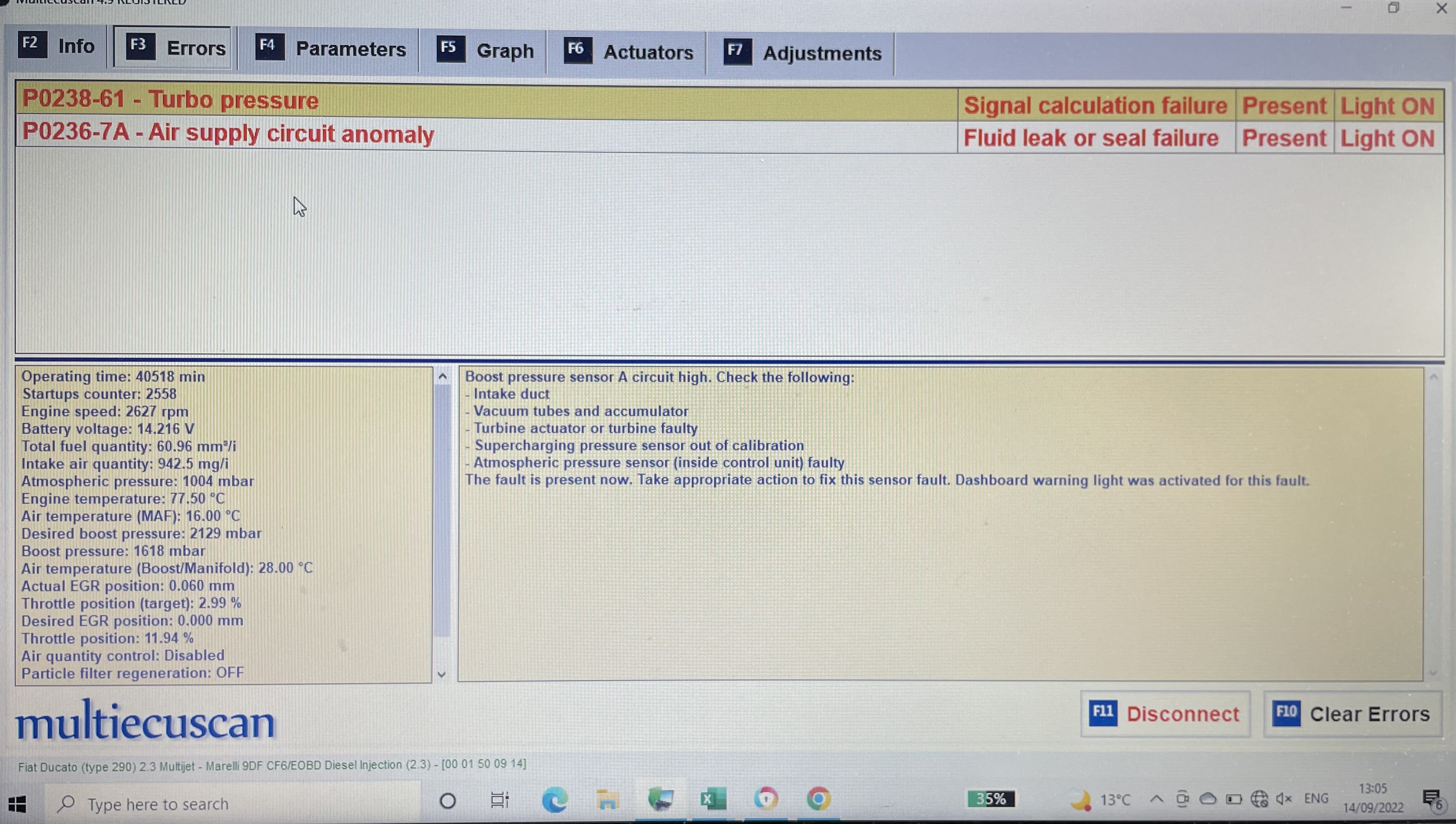

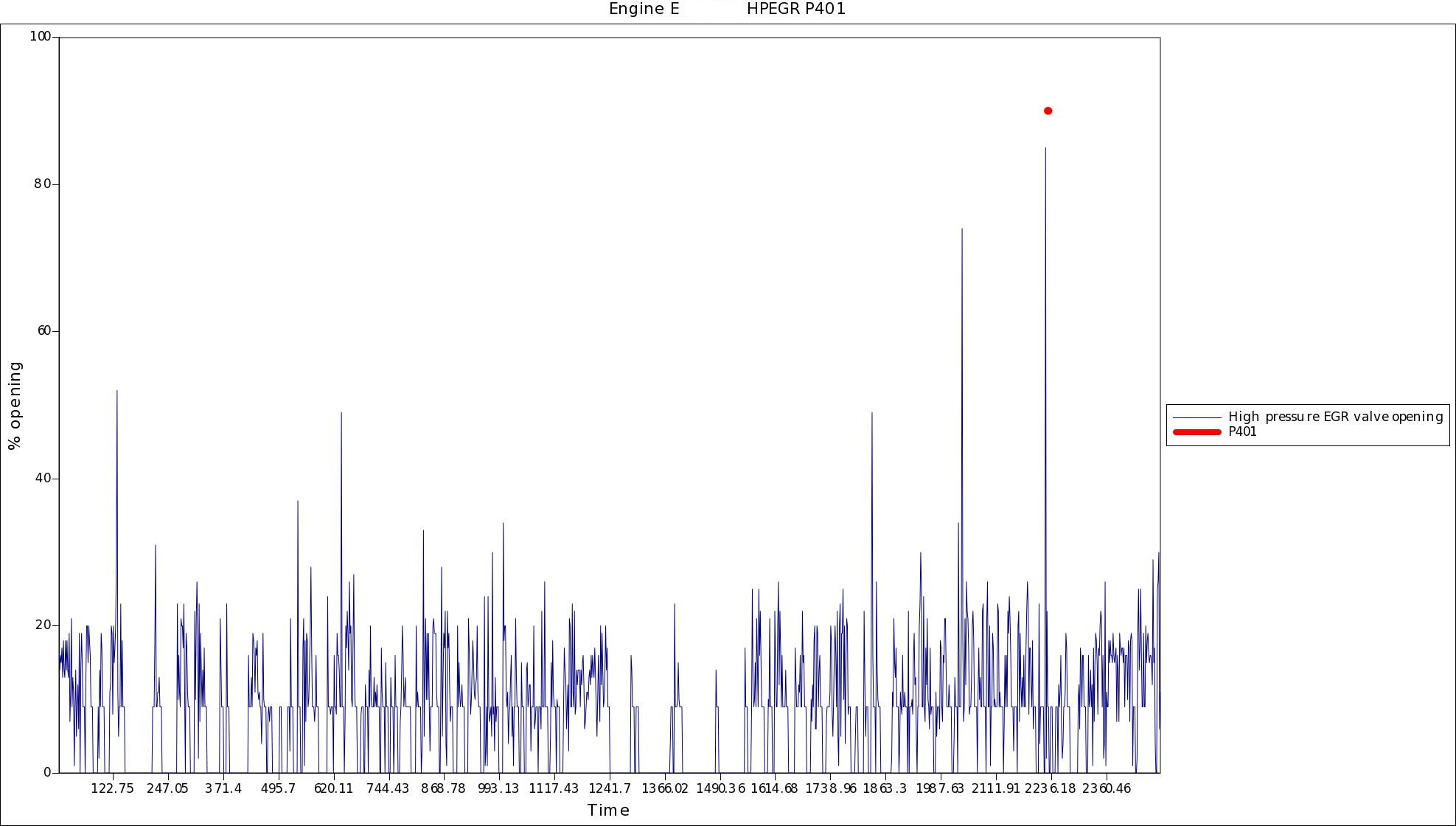

The 401 error always coincides with a large demand and inability to deliver it.

The example below show the HPEGR being asked to open to a much greater value than normal. In these examples the error coincides with the valve being asked to open greater than 80%.

The inability to flow the desired Air volume is generally not due to the egr value being unable to do its normal function but the ecu asking for an implausible value. This is due to an ecu error or air flow not being possible due to another condition.

If you have data similar to above the problem is probably not the HPEGR valve

What next

Inspect the exhaust pipe, wipe with a kitchen towel.

The first observation made is that a good engine has a clear clean exhaust pipe. An oily or sooty engine either needs attention or is still sooty as a result of previous issues.

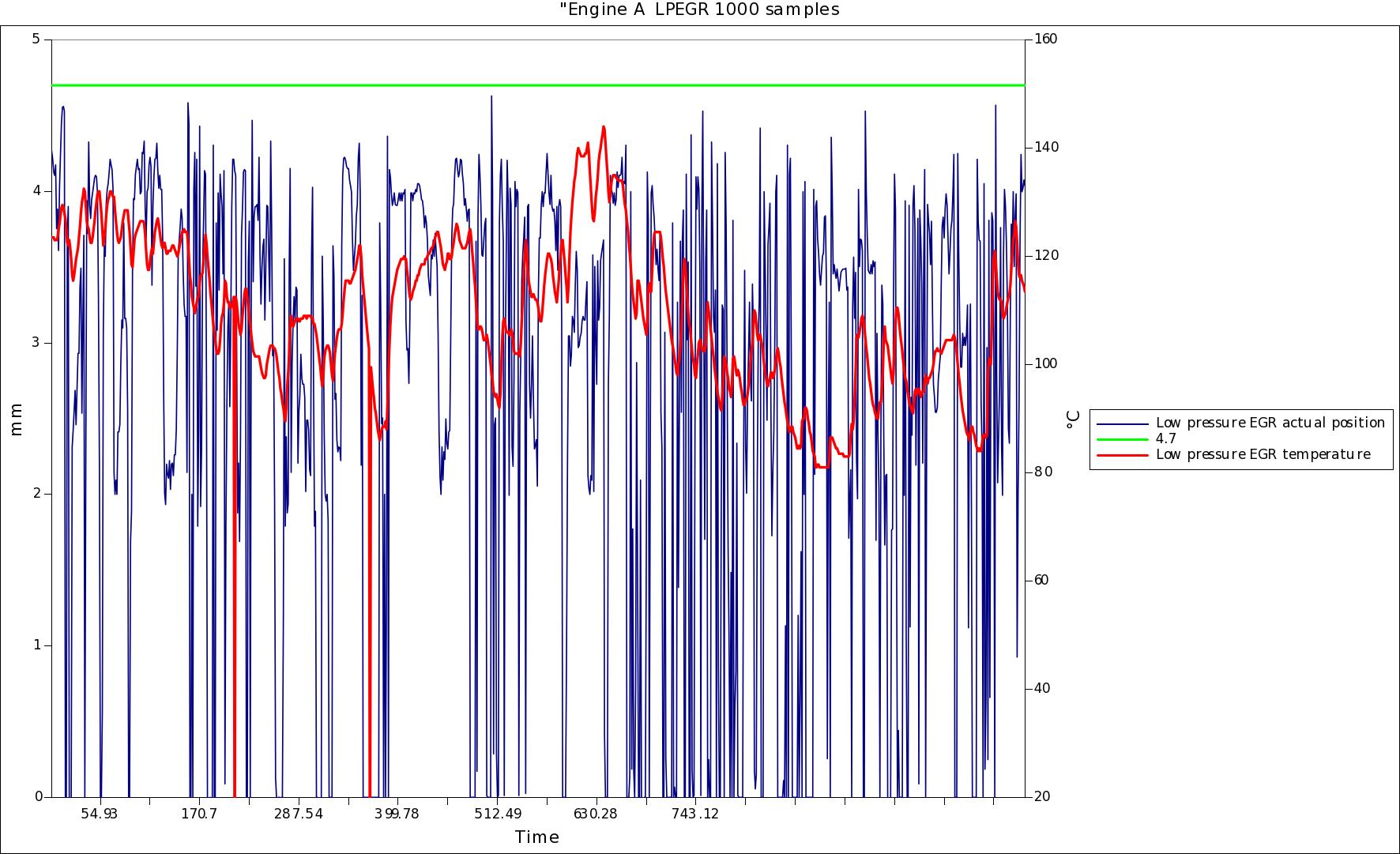

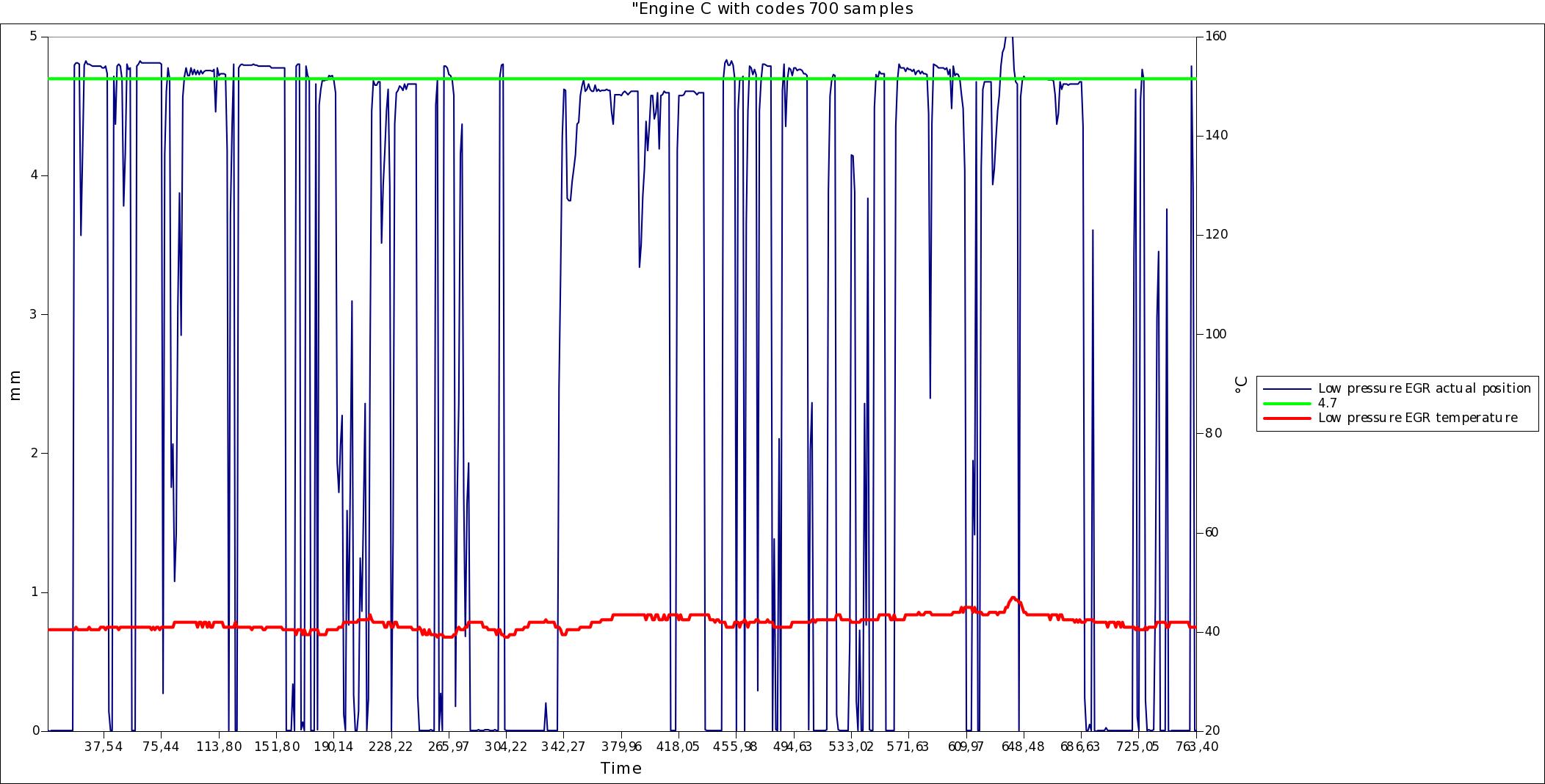

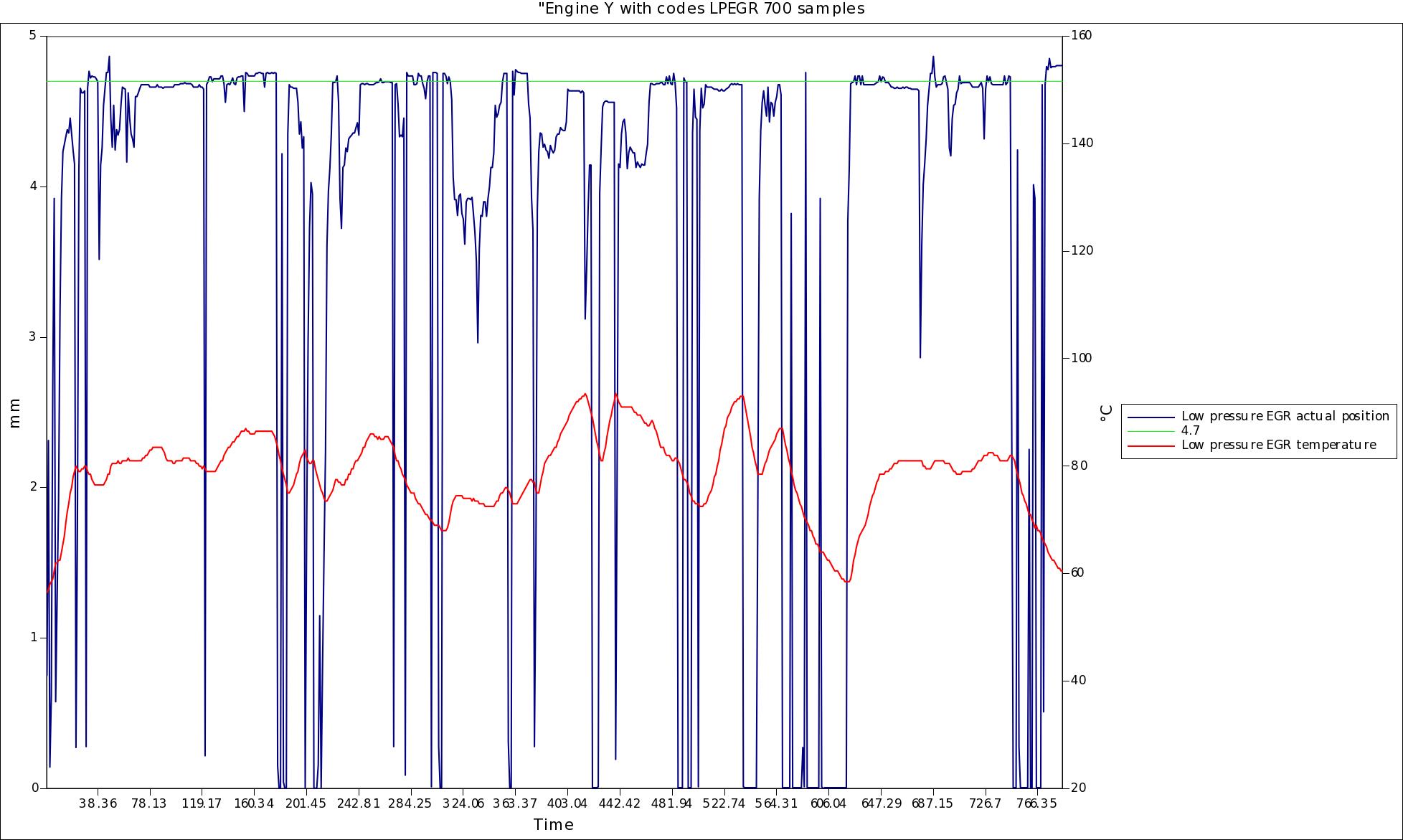

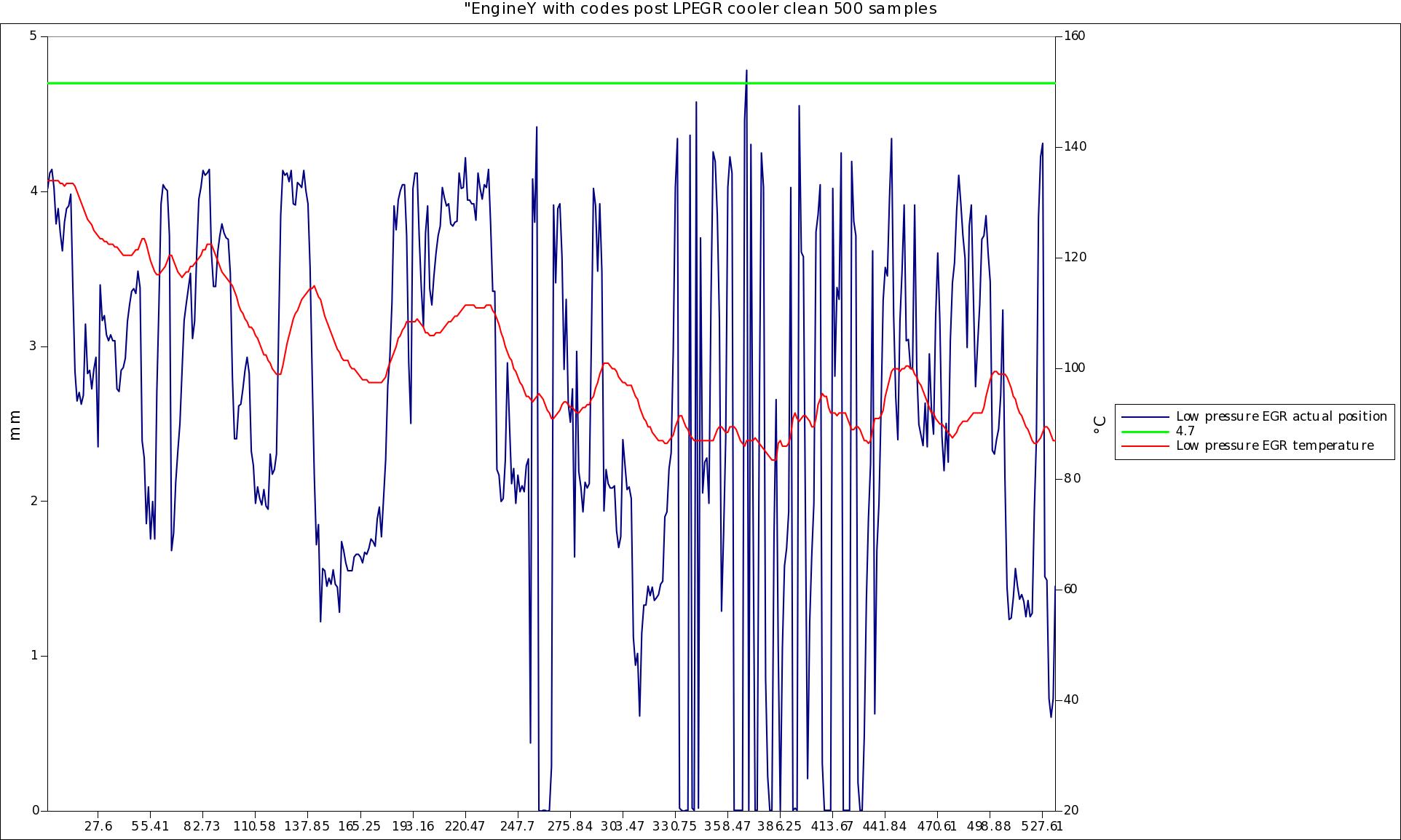

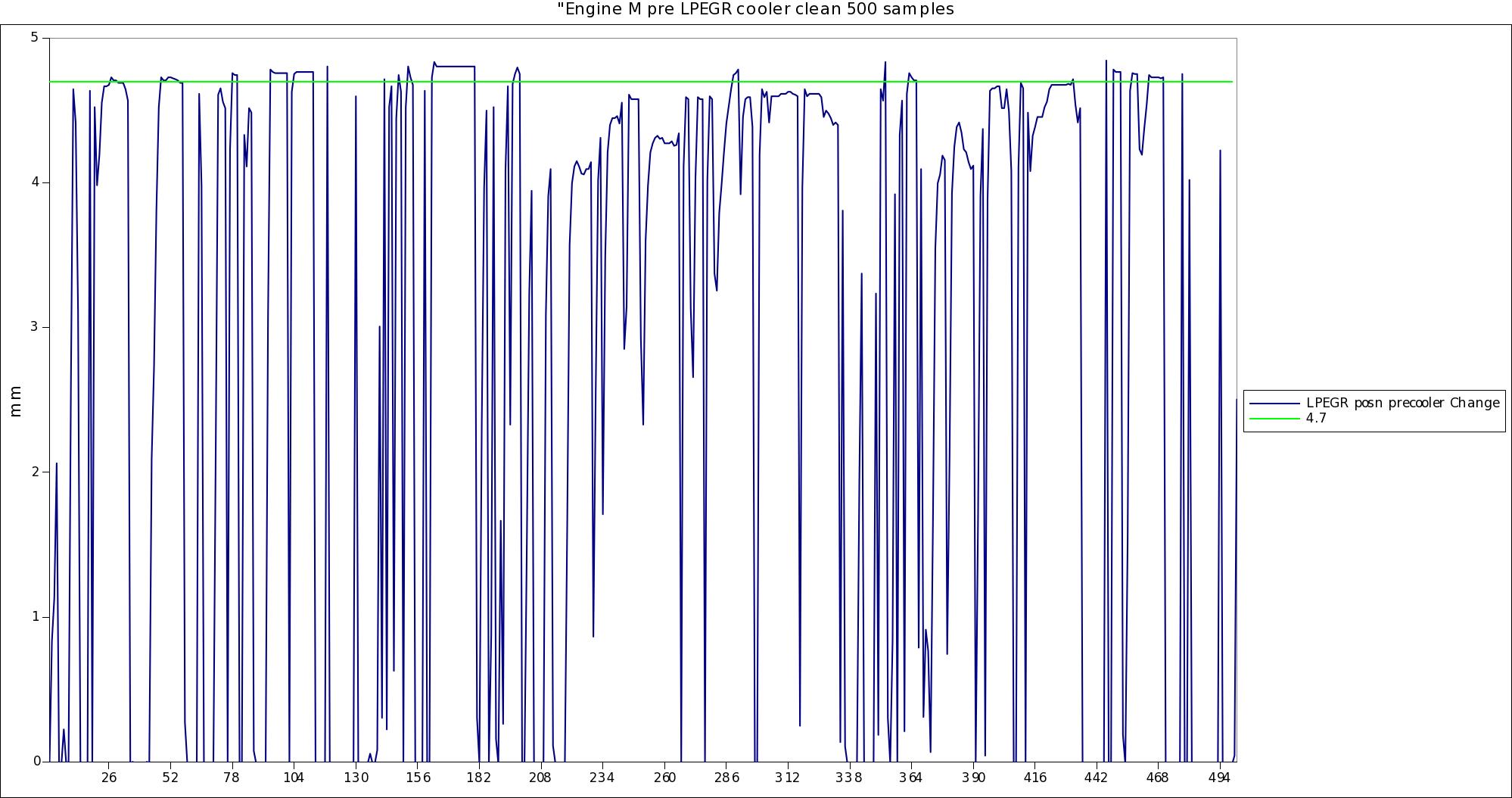

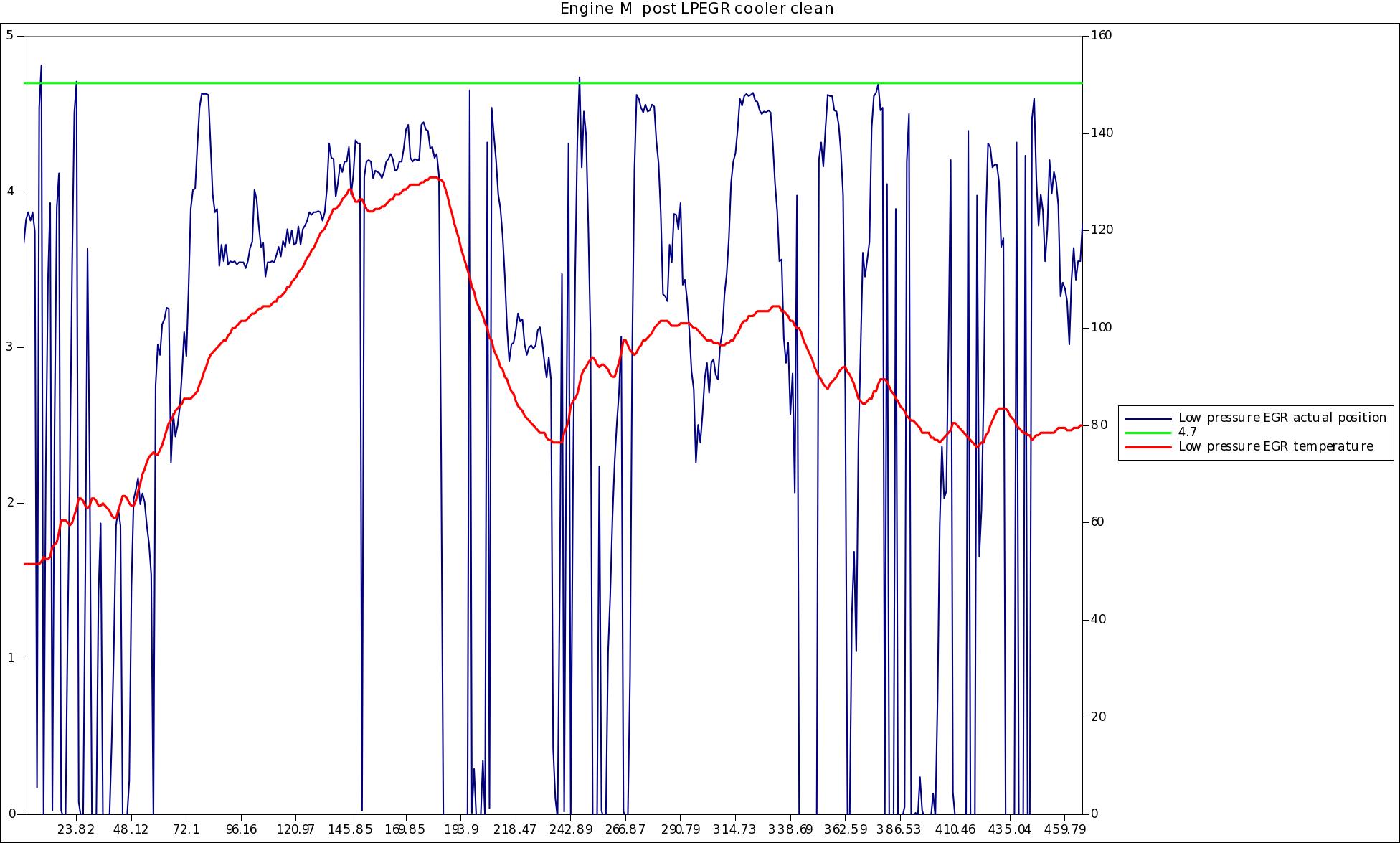

From the data collected earlier create a graph Showing the LPEGR valve opening values and the LPEGR cooler temperature.

This shows a good working system with opening showing differing control values from 2 to 3 mm and max to min 4.7 to 0mm.

A poorly system jumps between Max to min 4.7 to 0 mm.

The other factor to consider is the cooler temperature.

The control of the EGR valve is dynamic, ie depending on the amount of air flowing, temperatures (in a number of places) , RPM, the need for gas to be introduced to the LP loop, this means the valve can be set from closed to open and continuous values in between. A problematic engine doesn’t control the mixture of exhaust and fresh gas due to a blocked filter and tends be be either totally on or off.

In a poorly system the EGR valve is either trying to be fully open or closed, the LPEGR cooler temperature is very low compared to a working system.

These values vary depending on driving conditions, how do i decide whats good and bad.

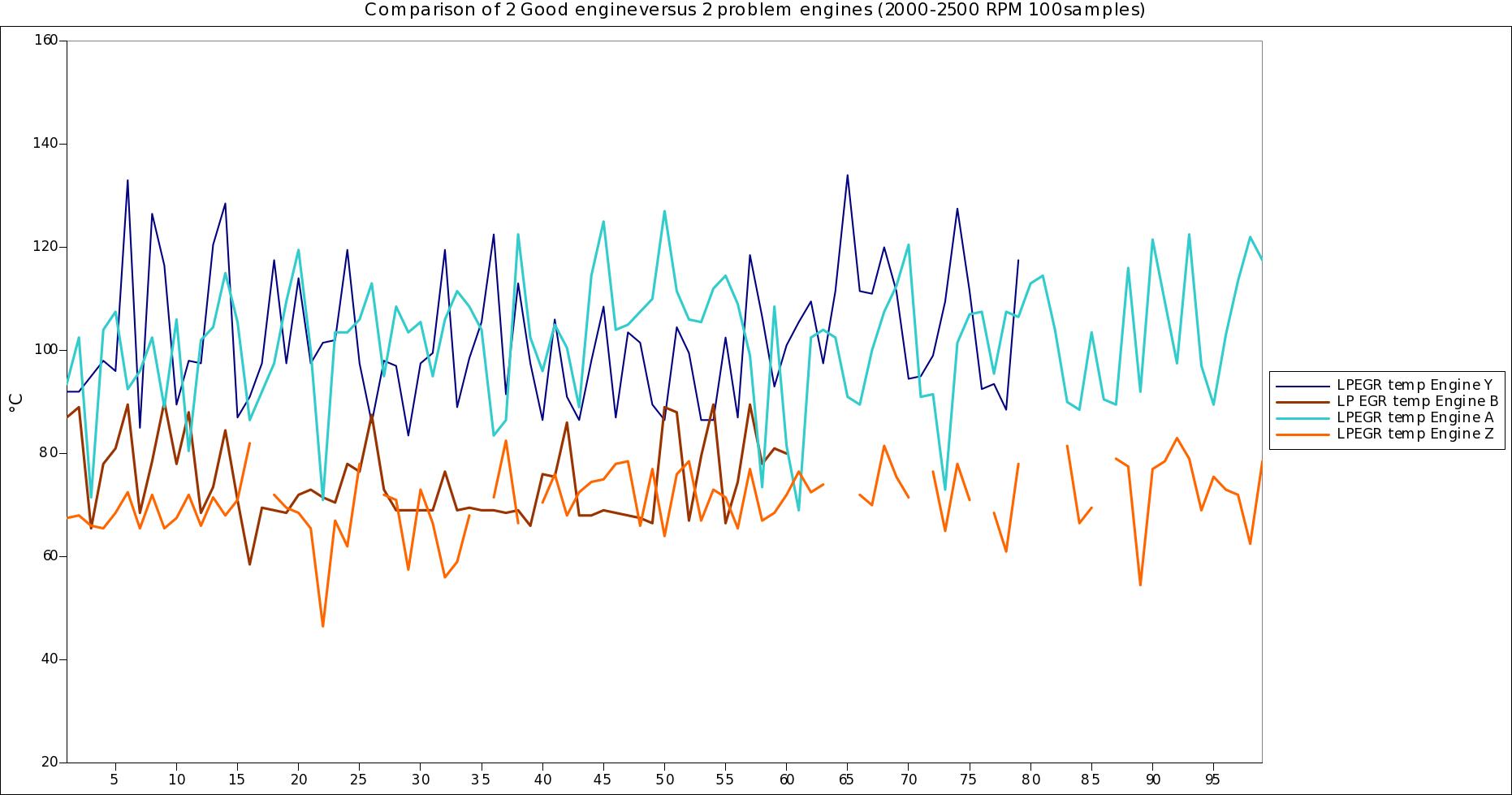

Do a sampling Run and copy the LPEGR temperature results to a spreadsheet . Take the mean and max and minimum of at least 100 samples and compare to the following table and graph . If your mean is above 100oC OK, if maximum is bellow 100oC you have a problem.

The results are from results sorted by RPM from 2000 to 2500rpm

Question :

My numbers are not the same, Max less than 100 but no codes

Answer :

Note this is a guide and not definitive. it is the result of my investigations and discussion with many Fiat Forum members, its their work i’m just reporting it.

There is no info published currently.

If your maximum is 130-140oC your'e probably OK

If you have doubts repeat the test and look for trends over months .

Post the CSV files on Fiat Forum and grovel for help.

Question :

I got some data, what is a spreadsheet, I don’t know what to do with the numbers, what should I do

Answer : Post the CSV files on Fiat Forum and grovel for help.

IF you have P0401 code sooty exhaust and a low LPEGR temperature you probably have a blocked cooler.

If other codes exist relating to pressure then the MAP sensor and turbo solenoid are suspect.

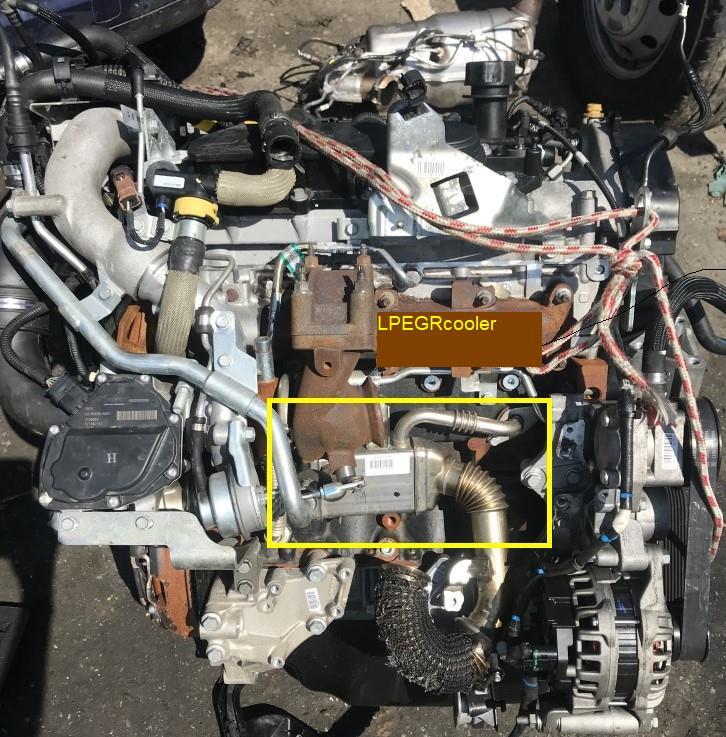

Where is the LPEGR cooler.

view from rear.

Six hours or so to remove and replace.

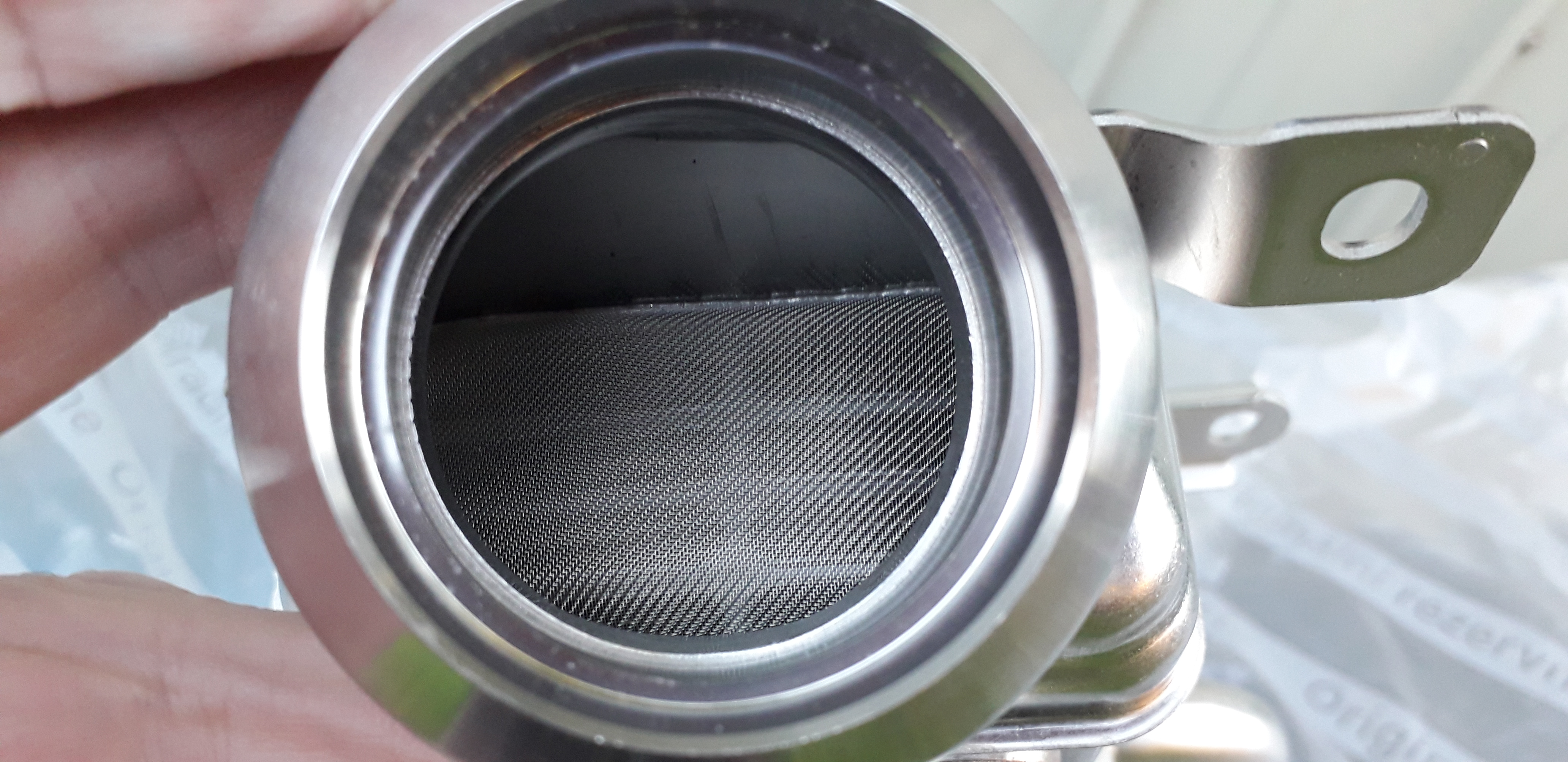

The blocked tea strainer in pristene as new condition looks like this

Map sensor Removal.

1 Undo and remove the hose clip on the throttle body, suitably squash the intercooler hose to displace it to your left (van rhs).

2 Use a mirror and torch to find the three fixing screws for the throttle body (1long at bottom two shorter at top. Now undo them, they are hex socket caphead setscrews, 5mm Allen key, you need an insert type with a 1/4 drive long extension.

Screws positioned at 2,6,10 oclock.

With screws removed you just move the throttle body out of the way STILL CONNECTED.

3 Now with torch locate the single fixing screw of the MAP, a small torx screw. Remove the screw and lift the sensor upwards out of it's hole.

Only now disconnect it's wiring plug.

The throttle body is now available for cleaning. Carb cleaner is suitable but dont squirt any where near the pivot just use a cloth soaked in cleaner.

Look to right of where throttle body is mounted, use a mirror to look inside the mixing chamber of the inlet manifold, look inside for the ***** (a domed headed cylinder with a centre hole), hope for just a cleanish light grey. (No gunge).

Sorry for poor quality picture

This the HPEGR

Question : How do i monitor a good engine

Answer : Regularly do a test run and monitor:

1 Injector variation

2 LPEGR Actual position

3 LPEGR cooler temperature

4 Physically inspect the exhaust pipe

This is an ongoing investigation so changes will be made. The information supplied here is very much on the basis you decide and no guarantee as to its veracity, it is what i think may be happening.

Any comments please add.

Note this is a guide and not definative. It is up to you to make decissions. It is the result of my investigations of data from many contributors and discussion with many Fiat Forum members, its their work I’m just reporting it. As it would be totaly unfair to mention just one and not to acknowledge all contributors i wont mention FredAstaire.

Question :

My van has thrown a P0401 code should I change the HPEGR valve?

Answer :

No. Not before reading the rest of this page.

A number of people have changed the HPEGR valve on the basis that the code is listed as.

P0401 Exhaust Gas Recirculation Flow Insufficient Detected

There has been no resolution of the problem as a result of the change.

What should I do?

With Multiecuscan check the freeze frame data for the error.

With Multiecuscan set to graph the following parameters. See tutorial

Tutorial to Measure specific Engine PIDs (Parameter ID) and Save data for analysis.

This was originally written to help one person with his Ducato totally new to MES to start saving data. it is not an exhaustive manual nor intended to be. Tutorial to Measure specific Engine PIDs (Parameter ID) and Save data for analysis. Open...

Comparison of 401 Freeze frame data

5 different engines and 4 results from engine G.

Tables

Engine | G | G | G | G | E | K | S | Z | |

Date | 23/5/2022 | 26/5/2022 | 9/6/2022 | 9/6/2022 | 13/7/2022 | 2/5/2022 | |||

operating time | 59611 | 59922 | 60081 | 60244 | 40159 | 436805 | 72032 | 77970 | |

Startup counter | 3018 | 3035 | 3046 | 3052 | 2533 | 15444 | 4659 | 4502 | |

Battery V | 14.352 | 14.538 | 14.406 | 14.43 | 14.054 | 14.43 | 14.299 | 14.191 | |

engine speed | 2010 | 1990 | 1802 | 1914 | 1791 | 1598 | 2089 | ||

air intake Qty | 765.1 | 804.5 | 683 | 711.5 | 611 | 842 | 683 | 625.5 | |

Desired air intake Qty | 2997.5 | 3185 | 2602.5 | 2709 | 2251.5 | 3406 | 2539 | 1893.5 | |

Engine temp | 82.5 | 73.5 | 79 | 81 | 74 | 85 | 60.5 | 78.5 | |

LPEGR | 4.68 | 4.68 | 4.7 | 4.68 | 4.69 | 4.74 | 4.77 | 4.65 | |

Boost Pressure | 1455 | 1461 | 1252 | 1333 | 1181 | 1499 | 1159 | 1050 | |

Ait temp (Boost/manifold | 37.5 | 30 | 37 | 36 | 28.5 | 35.5 | 33 | 25.5 | |

Desired EGR posn | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

Actual EGR posn | 0.014 | 0.06 | 0.021 | 0.044 | 0.06 | −0.011 | 0.021 | 0 | |

Total fuel qty | 45.92 | 49.84 | 37.46 | 38.98 | 31.1 | 42.56 | 34.84 | 18.92 | |

LPEGR target posn | 4.77 | 4.77 | 4.82 | 4.78 | 4.79 | 4.82 | 4.86 | 4.75 | |

Throttle position | 11.87 | 11.87 | 11.87 | 11.87 | 11.94 | 11.87 | 11.75 | 11.87 | |

Air quality control | Dissabled | Dissabled | Dissabled | Dissabled | Dissabled | Dissabled | | Dissabled | |

DPF Regen | off | off | off | off | off | off | off | ||

EGR exclusion valve | off | off | off | off | off | off | off | ||

Actual Air Intake % of Desired | 25.5 | 25.3 | 26.2 | 26.3 | 27.1 | 24.7 | 26.9 | 33.0 |

1 Actual Air Intake % of Desired is typicaly 25% with one example at 33%

2 LPEGR is fully open

3 All engines are warming up (EGR exclusion valve off) but close to temperature not cold.

4 Throttle position very close 6 of 8 11.87% others within .2%

The 401 error always coincides with a large demand and inability to deliver it.

The example below show the HPEGR being asked to open to a much greater value than normal. In these examples the error coincides with the valve being asked to open greater than 80%.

The inability to flow the desired Air volume is generally not due to the egr value being unable to do its normal function but the ecu asking for an implausible value. This is due to an ecu error or air flow not being possible due to another condition.

If you have data similar to above the problem is probably not the HPEGR valve

What next

Inspect the exhaust pipe, wipe with a kitchen towel.

The first observation made is that a good engine has a clear clean exhaust pipe. An oily or sooty engine either needs attention or is still sooty as a result of previous issues.

From the data collected earlier create a graph Showing the LPEGR valve opening values and the LPEGR cooler temperature.

This shows a good working system with opening showing differing control values from 2 to 3 mm and max to min 4.7 to 0mm.

A poorly system jumps between Max to min 4.7 to 0 mm.

The other factor to consider is the cooler temperature.

The control of the EGR valve is dynamic, ie depending on the amount of air flowing, temperatures (in a number of places) , RPM, the need for gas to be introduced to the LP loop, this means the valve can be set from closed to open and continuous values in between. A problematic engine doesn’t control the mixture of exhaust and fresh gas due to a blocked filter and tends be be either totally on or off.

In a poorly system the EGR valve is either trying to be fully open or closed, the LPEGR cooler temperature is very low compared to a working system.

These values vary depending on driving conditions, how do i decide whats good and bad.

Do a sampling Run and copy the LPEGR temperature results to a spreadsheet . Take the mean and max and minimum of at least 100 samples and compare to the following table and graph . If your mean is above 100oC OK, if maximum is bellow 100oC you have a problem.

Good | Good | Problematic | Problematic | ||

Mean | 102 | 118 | 75 | 72 | |

Max | 134 | 127 | 90 | 83 | |

Min | 83 | 69 | 58 | 47 |

The results are from results sorted by RPM from 2000 to 2500rpm

Question :

My numbers are not the same, Max less than 100 but no codes

Answer :

Note this is a guide and not definitive. it is the result of my investigations and discussion with many Fiat Forum members, its their work i’m just reporting it.

There is no info published currently.

If your maximum is 130-140oC your'e probably OK

If you have doubts repeat the test and look for trends over months .

Post the CSV files on Fiat Forum and grovel for help.

Question :

I got some data, what is a spreadsheet, I don’t know what to do with the numbers, what should I do

Answer : Post the CSV files on Fiat Forum and grovel for help.

IF you have P0401 code sooty exhaust and a low LPEGR temperature you probably have a blocked cooler.

If other codes exist relating to pressure then the MAP sensor and turbo solenoid are suspect.

Where is the LPEGR cooler.

view from rear.

Six hours or so to remove and replace.

The blocked tea strainer in pristene as new condition looks like this

Map sensor Removal.

1 Undo and remove the hose clip on the throttle body, suitably squash the intercooler hose to displace it to your left (van rhs).

2 Use a mirror and torch to find the three fixing screws for the throttle body (1long at bottom two shorter at top. Now undo them, they are hex socket caphead setscrews, 5mm Allen key, you need an insert type with a 1/4 drive long extension.

Screws positioned at 2,6,10 oclock.

With screws removed you just move the throttle body out of the way STILL CONNECTED.

3 Now with torch locate the single fixing screw of the MAP, a small torx screw. Remove the screw and lift the sensor upwards out of it's hole.

Only now disconnect it's wiring plug.

The throttle body is now available for cleaning. Carb cleaner is suitable but dont squirt any where near the pivot just use a cloth soaked in cleaner.

Look to right of where throttle body is mounted, use a mirror to look inside the mixing chamber of the inlet manifold, look inside for the ***** (a domed headed cylinder with a centre hole), hope for just a cleanish light grey. (No gunge).

Sorry for poor quality picture

This the HPEGR

Question : How do i monitor a good engine

Answer : Regularly do a test run and monitor:

1 Injector variation

2 LPEGR Actual position

3 LPEGR cooler temperature

4 Physically inspect the exhaust pipe

This is an ongoing investigation so changes will be made. The information supplied here is very much on the basis you decide and no guarantee as to its veracity, it is what i think may be happening.

Any comments please add.