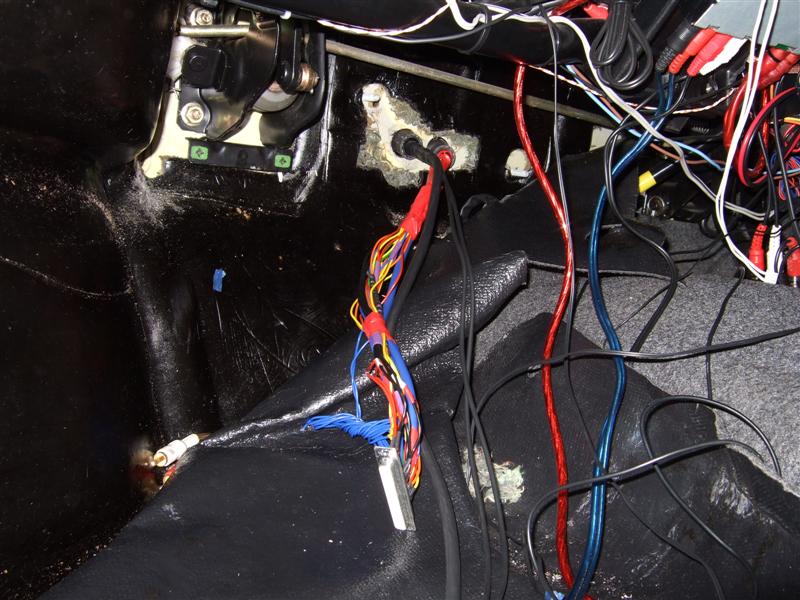

25mm hole saw, 25mm gromet. should fit... i was gonna carry on and just use some 5/8's pipe i had kicking about.. that fits the hole and the wires would fit through.. but i'm not gonna start bodging it now!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General chii rebuild

- Thread starter arc

- Start date

Currently reading:

General chii rebuild

Here's a bodge disguised as an improvement. For it to work you have to be 100% sure you'll not need to put another wire through that hole.

Feed the wires through -- all of them. Chop the grommet so you can fit it into the hole. Put on some rubber gloves. Put a little Sikkaflex round the edge of the hole and pop the butchered grommet in. Finally, squirt Sikkaflex into and around thre hole that's now filled with wires.

It'll still be possible to remove, albeit with great difficulty, but you'll have -- at least in that instance -- an airtight seal between the engine compartment and the passenger compartment so that when things go smelly on the dirty side of the firewall you won't be affected.

Feed the wires through -- all of them. Chop the grommet so you can fit it into the hole. Put on some rubber gloves. Put a little Sikkaflex round the edge of the hole and pop the butchered grommet in. Finally, squirt Sikkaflex into and around thre hole that's now filled with wires.

It'll still be possible to remove, albeit with great difficulty, but you'll have -- at least in that instance -- an airtight seal between the engine compartment and the passenger compartment so that when things go smelly on the dirty side of the firewall you won't be affected.

hehe. am gonna get some 23mm wiring gromets tomorrow and us them. and then seal them up just to make sure

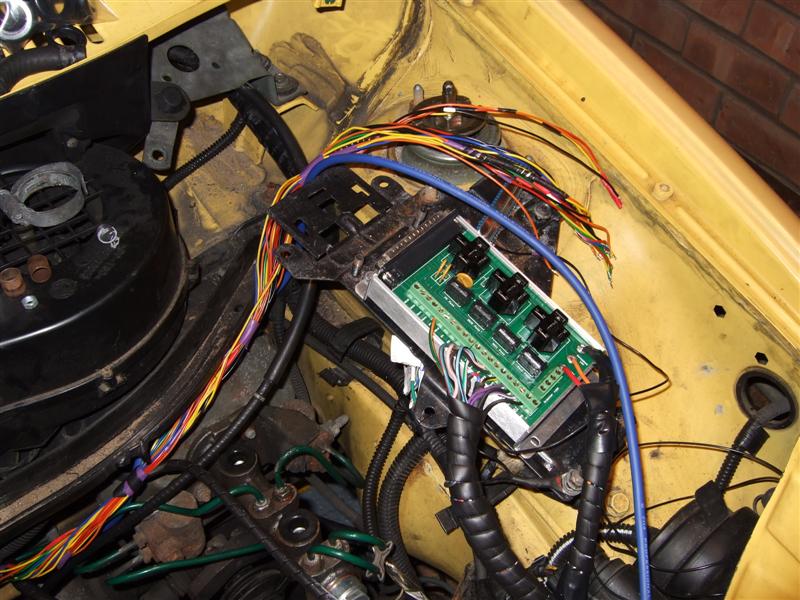

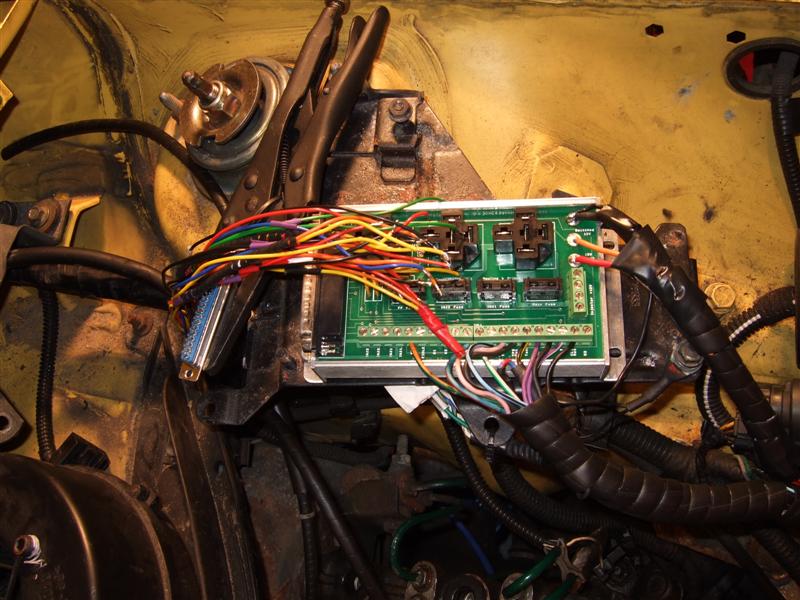

well this took longer than i thought, but ive been doing other stuff whilst too.. anyhoo

silly me bought the wrong cable, so thats not quite finished. it doesnt have the TDC sensor cable (though u can see it in some pics.. wrong cable though.. shhh ) in nor does it have the additional cabling in for boost control, knock, dual table etc (but that'd be easy to add tomorrow, when ive the other bits i need)

) in nor does it have the additional cabling in for boost control, knock, dual table etc (but that'd be easy to add tomorrow, when ive the other bits i need)

silly me bought the wrong cable, so thats not quite finished. it doesnt have the TDC sensor cable (though u can see it in some pics.. wrong cable though.. shhh

Aha! Coming on!

The top pic looks a bit like the inside of Yellow at the moment, except I'm just trying to fit an alarm! Sodding wiring.......................

The top pic looks a bit like the inside of Yellow at the moment, except I'm just trying to fit an alarm! Sodding wiring.......................

Will it start on the first turn of the key

Will it start on the first turn of the key

no chance.

Will it start on the first turn of the key

no chance.

thats what i like to see, pure confidence

its looking good though Arc should be nice when it gets on the road

wayne

ok. suppose i should some updates. i have kinda lost my enthuasism with this at the moment though. not having much time to work on it, and then when i do have time im off buying bits and pieces i need.. but anyway, heres an update

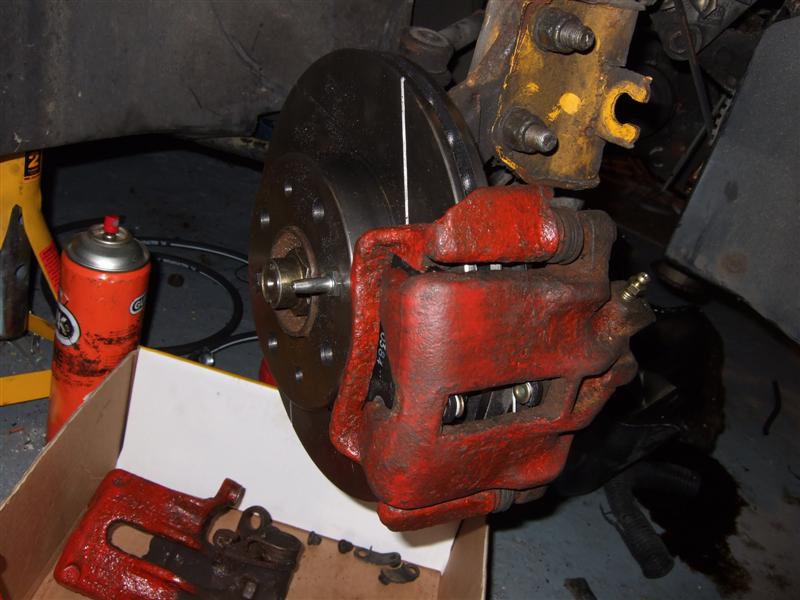

UT brakes are on (just need to fit the pads). Stone guards need to be removed else they dont fit.

inlet manifold, tb, injectors, fuel rail, head etc are all on. Spesso gasket fitted, all torqued down.

all (asside from the injectors) wiring in the engine bay is done. fuel pressure reg is bolted to the firewall.

bought some bits to stick in the sump. bits for an oil breather, bits to add an oil return from the catch tank back to the sump and bits to add temp sender in there too.

spare bits live in the boot, oo look a supersprint manifold and a CDA airbox.

and ive not done a lot to the dash.. you can see the megasquirt wiring in the passenger footwell.

and these turned the other day. Air Fuel gauge, Oil temperature gauge and exhaust temperature gauge. and a 3 pod facia thingy (and a new rug)

i'm still waiting on an oil pressure and vacuum gauge. so will be filling the a-pillar pods, and then replacing the centre heater vent with the remaining 3 gauges.

FYI, using a bolt and a screw driver instead of a chuck-key isn't a grand idea.. it works, but if you slip you might well stab yourself in the finger and bleed all over the place.

UT brakes are on (just need to fit the pads). Stone guards need to be removed else they dont fit.

inlet manifold, tb, injectors, fuel rail, head etc are all on. Spesso gasket fitted, all torqued down.

all (asside from the injectors) wiring in the engine bay is done. fuel pressure reg is bolted to the firewall.

bought some bits to stick in the sump. bits for an oil breather, bits to add an oil return from the catch tank back to the sump and bits to add temp sender in there too.

spare bits live in the boot, oo look a supersprint manifold and a CDA airbox.

and ive not done a lot to the dash.. you can see the megasquirt wiring in the passenger footwell.

and these turned the other day. Air Fuel gauge, Oil temperature gauge and exhaust temperature gauge. and a 3 pod facia thingy (and a new rug)

i'm still waiting on an oil pressure and vacuum gauge. so will be filling the a-pillar pods, and then replacing the centre heater vent with the remaining 3 gauges.

FYI, using a bolt and a screw driver instead of a chuck-key isn't a grand idea.. it works, but if you slip you might well stab yourself in the finger and bleed all over the place.

Last edited:

FYI, using a bolt and a screw driver instead of a chuck-key isn't a grand idea.. it works, but if you slip you might well stab yourself in the finger and bleed all over the place.

ive never done that

works looking good and youve got some nice kit there, although the loom looks scary at first you seem to have done a tidy job of it

on another note its clear to see your spending a lot of time and money on a 1.2 8v to make it quite special and unique but i just wondered that as youve taken the effort to go MPi etc why you havent gone for the 16v conversion aswell? extra cost and the need of aftermarklet management are some of the reasons others dont go this route yet you have already done all that on your 8v so abviously not one of these

as you know im really thinking of the 16v route for my mk1 this year :yum: and would appreciate your idea of the pros and cons of each conversion as no one as far as i have seen on here has gone as indepth on tuning the 1242 in a cento aside from ems sei

wayne

this car has always been built with the intent of turboing it.

to turbo a cinq running stock ECU is a faff and a bodge, however im not daft enough to jump into a turbo conversion and ECU swap at the same time. this is mainly a learning experience for me, i wanted to learn about ECUs.. so i am. When i want the turbo fitted.. well already have the manifold, and the oil returns - not much more than a bespoke exhaust and a bit induction piping to do there!

I don't want a 16v engine - quite happy with my 8v motor, it's hardly in stock tune!

to turbo a cinq running stock ECU is a faff and a bodge, however im not daft enough to jump into a turbo conversion and ECU swap at the same time. this is mainly a learning experience for me, i wanted to learn about ECUs.. so i am. When i want the turbo fitted.. well already have the manifold, and the oil returns - not much more than a bespoke exhaust and a bit induction piping to do there!

I don't want a 16v engine - quite happy with my 8v motor, it's hardly in stock tune!

- Joined

- Feb 11, 2006

- Messages

- 6,866

- Points

- 1,040

Engine bay still looks how it did when I saw her Arc, slacker

ahh but the head is torqued etc now and the inlet manifold is all properly attached, and i know now my strut brace dont fit!

- Joined

- Feb 11, 2006

- Messages

- 6,866

- Points

- 1,040

ahh but the head is torqued etc now and the inlet manifold is all properly attached, and i know now my strut brace dont fit!

I'll let you off then, btw i may be leaving the cento world but i still want to know when she's running, might even make a day of it and nip over when she does go, least then I might get a ride in a fast cento at least......... (you taking notes alex

- Joined

- Feb 11, 2006

- Messages

- 6,866

- Points

- 1,040

Not for long with no sump

your cars too low you seem to have knocked your sump off

nealry knocked it off, its been decked though so thought it best change it..to one with bonus holes for sump breathers and temp sensors and oil returns and stuffx

Similar threads

- Replies

- 5

- Views

- 1K