I have a x250 3.0 2007 Citroen, after going on a trip this weekend (2x 45 min drive) I noticed the van was starting a bit more difficult and checked the battery voltage in the back (where the DC-DC charger for the leisure battery is, leisure battery disconnected at the moment) and it only indicated 12.2V. The DC-DC charger is connected directly with the fuse panel mounted on the positive terminal of the starter battery. When measuring under the bonnet at the indicated jump start point I get 14.8V. So it seems the alternator is running fine. Also no battery charging warning light on the dashboard.

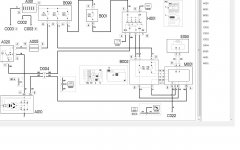

I'm thinking about a loose connection or wire damage somewhere. Are there any weak spots in the charging circuit of the x250? I probably should start looking in the battery compartment and check for blown fuses or wire damage. How can I identify the cable coming from the alternator?

I'm thinking about a loose connection or wire damage somewhere. Are there any weak spots in the charging circuit of the x250? I probably should start looking in the battery compartment and check for blown fuses or wire damage. How can I identify the cable coming from the alternator?