- Joined

- Sep 14, 2009

- Messages

- 19,899

- Points

- 3,413

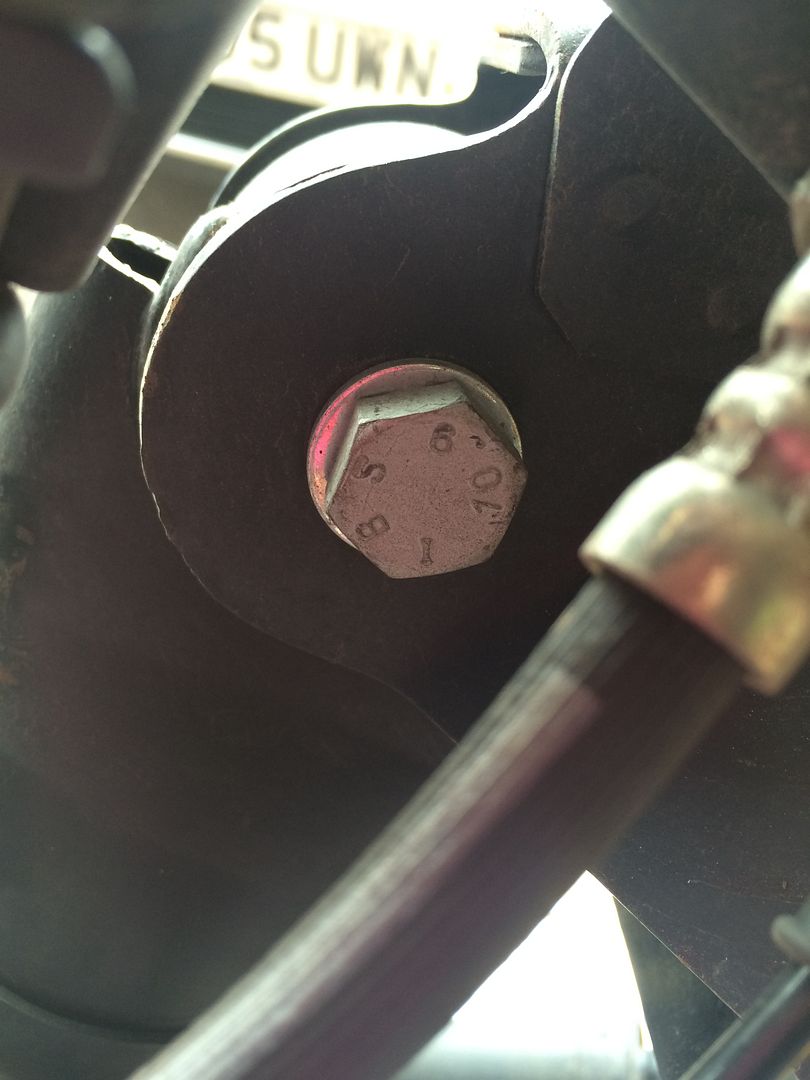

Ive bitten the bullet and bought a complete 2015 500 rear axle. It's an upgrade from the Panda axle so needs the full set.

Axle, hubs, all brake pipes, hand brake cables, springs and shocks. All for £165.

I'm about to strip the gubbins away and Hammerite the whole thing. Pix to follow.

Axle, hubs, all brake pipes, hand brake cables, springs and shocks. All for £165.

I'm about to strip the gubbins away and Hammerite the whole thing. Pix to follow.