John H

Established member

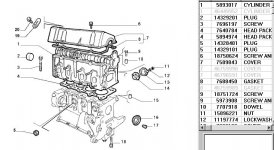

Just over a week ago I finally changed the gasket (and head) on my '93 CLX, and it's running really well at the moment - it also starts nicer than it's ever done in the 2 1/2 years I've owned it.

I swapped the head becuase I didn't like the look of the face that much, as it has obviously suffered some corrosion damage due to lack of fresh antifreeze, but the vital area immediately adjacent to the bores looks OK.

Early hours of sunday morning our youngest comes home in the '93 "Parade": "I'm freezing! - the heater doesn't work any more, and the temperature gauge went up to 110 on the way home".

No prizes for guessing what I was doing yesterday:

head off the "Parade".

Now the head face on that head is a lot cleaner, but number 3 cylinder looks like it's fresh off the assembly line - bright shiny piston top, I could even read the numbers and see the arrow. Whereas the others are the usual carbon deposits.

The edge of the cylinder head for number 3 cylinder has a small but significant "V" nick in the edge - I think I can guess where all the coolant went

It might respond to a skim, but the damage may be too deep.

Meanwhile - I put the old CLX head on.

Used a 8UKP head gasket set I got on Ebay a while ago, and so far so good - but it's a bit more "tappety" than the other head, but it has 40K more miles on it....

Will have to see how they both fare over the coming months (and see what can be done with the "newer" head.

As an aside, I think the answer to something which puzzled me a bit has come to light:

the exhaust on the "Parade" would sometimes look really clean, rather than the slightly sooty look which seems to be the norm for my Panda - I had thought it was a less worn engine just running that bit cleaner.

Perhaps it was a bit of coolant leakage before the total loss?

Regards

John H

I swapped the head becuase I didn't like the look of the face that much, as it has obviously suffered some corrosion damage due to lack of fresh antifreeze, but the vital area immediately adjacent to the bores looks OK.

Early hours of sunday morning our youngest comes home in the '93 "Parade": "I'm freezing! - the heater doesn't work any more, and the temperature gauge went up to 110 on the way home".

No prizes for guessing what I was doing yesterday:

head off the "Parade".

Now the head face on that head is a lot cleaner, but number 3 cylinder looks like it's fresh off the assembly line - bright shiny piston top, I could even read the numbers and see the arrow. Whereas the others are the usual carbon deposits.

The edge of the cylinder head for number 3 cylinder has a small but significant "V" nick in the edge - I think I can guess where all the coolant went

It might respond to a skim, but the damage may be too deep.

Meanwhile - I put the old CLX head on.

Used a 8UKP head gasket set I got on Ebay a while ago, and so far so good - but it's a bit more "tappety" than the other head, but it has 40K more miles on it....

Will have to see how they both fare over the coming months (and see what can be done with the "newer" head.

As an aside, I think the answer to something which puzzled me a bit has come to light:

the exhaust on the "Parade" would sometimes look really clean, rather than the slightly sooty look which seems to be the norm for my Panda - I had thought it was a less worn engine just running that bit cleaner.

Perhaps it was a bit of coolant leakage before the total loss?

Regards

John H