Right First off this is an involving task requiring some specialist tools and a bit of care and attention to detail get it wrong and there is a risk of serious damage to your engine....

Tools/ equipment needed

basic tools:

selection of socket sets i used a mixture of my 1/4" 3/8" 1/2" sets

Breaker bar

Large and small torque wrenches

Slotted and pozi screwdrivers

T25 torx driver

2x trolley jacks

1x axle stand

Cam belt kit

Replacement Aux belt

Crow bar

Mallet

Marker pen

liquid gasket compound (for rocker box top gasket)

8 10 15 24 mm Combination spanners

1/2" drive T55 Male Torx socket

E14 E18 Female Torx sockets (for engine mount)

Cam locking and timing kit (ensure you get the correct one for your engine look at your VIN plate in the boot and match the engine type code to the kit.

)

Fiat ECU / MULTI ECU scan + leads / a garage with the relevent software and leads to carry out a Phonic wheel relearn

so park the car somewhere safe and level chock the wheels and leave out of gear...

Disconnect battery (check you still have radio code if after market HU fitted)

remove the Air box as described here:

https://www.fiatforum.com/grande-punto-guides/234763-spark-plug-change-1-2-8v.html

Next remove the Coil pack (3x 10mm bolts) and carefully tuck out of the way

now carefully remove the 2 plugs from the engine management computer (the red levers lift up and eject the plug do not force them) Mark them left and right with the marker pen so you know which goes in which hole when you come to refit

then undo the 4x 10mm nuts and put computer in a safe place where you wont kick it or stand on it

next remove the computer mount (1 nut and 3 bolts)

Remove the engine earth link and the Lambada sensor plug and cable support bracket.

Remove the Cam position sensor (and solonoid plug / wiring (vvt only))

Now remove the upper cam protection cover (3x 10mm headed bolts)

remove with care freeing the cable that is held in the channel in the cover

now loosen the engine support bolts (do not remove just loosen) using the E torx sockets..

and slacken 3x alternator bolts pull alternator towards front of the car and remove Axillary belt

and remove Rocker box top (8x 8mm headed bolts) and gasket

Remove the drivers side front wheel and arch liners (obviously jack and axle stands)

Now remove Alternator drive pulley (3x15mm headed bolts)

and remove lower cam belt cover (1x 10mm headed bolt)

exposing crank pully (note the dimple thats the timing reference mark for the locking tool)

now place a block of wood under sump and remove the entire engine mount..

the cam belt and tensioner should now be fully visible..

Now before you go any further ensure the engine is "in time"

with a spanner on the crank pully rotate the engine till the cam locking tool fits in the slot on the crankshaft end

(watch you don't damage the rocker top seal)

now there is 2 turns of the crank which gives one turn of the cam it is possible that at first your cam will be 180 degrees out of time with the cam when trying to fit the cam locking plate..

this is 180 degrees out:

if that is the case rotate the crank until both locking tools line up hold the crank one in place initially so you can see if its in line or not..

Then fit lower locking tool ensuring its the correct way round and that the dimple on the crank goes into the hole in the tool and secure in place with the bolts in the kit

now with a 13mm spanner loosen the cam tensioner and remove it and the belt..

THOSE WITH VVT READ PAGE 2 NOW!!!!....

SEE PAGE 3 for water pump replacement at this point

put on new cam tensioner and do up nut finger tight

next slacken off Cam pully

FIRST REMOVE CAM LOCKING TOOL or you can damage your camshaft end

loosen using a 24mm spanner on the flats on the cam shaft and a T55 torx socket

(i took this pic as i was refitting a torque wrench shouldn't be used for removal)

Refit locking tool

now rotate the cam pully fully clockwise till it hits the stop

Now wash your hands and degrease the rollers and tensioners using brake cleaner or flash degreaser

take out your new belt and starting at the cam pulley go round clockwise

Cam - waterpump - crank - tensioner

Get the 2 pin tensioner tool from cam belt tool kit and turn it gently anticlockwise till it hits the stop (ie max tension) then hold and torque bolt to 28 NM and Remove locking tools

place spanner on cam again and this time tighten the Cam torx bolt to 70NM

rotate the engine twice by hand (spanner on crank pulley) this beds in the belt

now loosen off the 13 mm tensioner nut carefully at the same time hold the tensioner with the pin spanner so as not to let fully loose tension and align the tension indicator as below:

tensioner fork highlighted:

this is too slack:

again highlighted (the back fork is to the left of the front fork)

rotate engine again by hand several turns then check indicator is sill showing correct tension and refit timing tools to check timing is spot on and its not jumped a tooth or anything like that

ensure all tools have been removed

REFIT LOWER CAM GUARD NOW or you wont get it back on

next refit lower alternator pulley (ensure dimple lines up with hole in pulley)

at this point its easier to refit and tension the alternator belt as the engine mount isn't on to tension fit new belt then pry back the alternator using a pry bar then do up 3 bolt on alternator the belt should just be able to be rotated about 90 degrees with your fingers...

Now put it all back together

rocker box gasket should be refitted like this

https://www.fiatforum.com/punto-gui...ket-without-having-leak-again-week-later.html

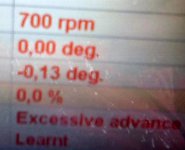

next run a Phonic wheel learn on MES / FES to allow the car to learn the slight change in Cam / Crank position due to the new unstretched belt

and enjoy another 4-5 years motoring...

Tools/ equipment needed

basic tools:

selection of socket sets i used a mixture of my 1/4" 3/8" 1/2" sets

Breaker bar

Large and small torque wrenches

Slotted and pozi screwdrivers

T25 torx driver

2x trolley jacks

1x axle stand

Cam belt kit

Replacement Aux belt

Crow bar

Mallet

Marker pen

liquid gasket compound (for rocker box top gasket)

8 10 15 24 mm Combination spanners

1/2" drive T55 Male Torx socket

E14 E18 Female Torx sockets (for engine mount)

Cam locking and timing kit (ensure you get the correct one for your engine look at your VIN plate in the boot and match the engine type code to the kit.

)

Fiat ECU / MULTI ECU scan + leads / a garage with the relevent software and leads to carry out a Phonic wheel relearn

so park the car somewhere safe and level chock the wheels and leave out of gear...

Disconnect battery (check you still have radio code if after market HU fitted)

remove the Air box as described here:

https://www.fiatforum.com/grande-punto-guides/234763-spark-plug-change-1-2-8v.html

Next remove the Coil pack (3x 10mm bolts) and carefully tuck out of the way

now carefully remove the 2 plugs from the engine management computer (the red levers lift up and eject the plug do not force them) Mark them left and right with the marker pen so you know which goes in which hole when you come to refit

then undo the 4x 10mm nuts and put computer in a safe place where you wont kick it or stand on it

next remove the computer mount (1 nut and 3 bolts)

Remove the engine earth link and the Lambada sensor plug and cable support bracket.

Remove the Cam position sensor (and solonoid plug / wiring (vvt only))

Now remove the upper cam protection cover (3x 10mm headed bolts)

remove with care freeing the cable that is held in the channel in the cover

now loosen the engine support bolts (do not remove just loosen) using the E torx sockets..

and slacken 3x alternator bolts pull alternator towards front of the car and remove Axillary belt

and remove Rocker box top (8x 8mm headed bolts) and gasket

Remove the drivers side front wheel and arch liners (obviously jack and axle stands)

Now remove Alternator drive pulley (3x15mm headed bolts)

and remove lower cam belt cover (1x 10mm headed bolt)

exposing crank pully (note the dimple thats the timing reference mark for the locking tool)

now place a block of wood under sump and remove the entire engine mount..

the cam belt and tensioner should now be fully visible..

Now before you go any further ensure the engine is "in time"

with a spanner on the crank pully rotate the engine till the cam locking tool fits in the slot on the crankshaft end

(watch you don't damage the rocker top seal)

now there is 2 turns of the crank which gives one turn of the cam it is possible that at first your cam will be 180 degrees out of time with the cam when trying to fit the cam locking plate..

this is 180 degrees out:

if that is the case rotate the crank until both locking tools line up hold the crank one in place initially so you can see if its in line or not..

Then fit lower locking tool ensuring its the correct way round and that the dimple on the crank goes into the hole in the tool and secure in place with the bolts in the kit

now with a 13mm spanner loosen the cam tensioner and remove it and the belt..

THOSE WITH VVT READ PAGE 2 NOW!!!!....

SEE PAGE 3 for water pump replacement at this point

put on new cam tensioner and do up nut finger tight

next slacken off Cam pully

FIRST REMOVE CAM LOCKING TOOL or you can damage your camshaft end

loosen using a 24mm spanner on the flats on the cam shaft and a T55 torx socket

(i took this pic as i was refitting a torque wrench shouldn't be used for removal)

Refit locking tool

now rotate the cam pully fully clockwise till it hits the stop

Now wash your hands and degrease the rollers and tensioners using brake cleaner or flash degreaser

take out your new belt and starting at the cam pulley go round clockwise

Cam - waterpump - crank - tensioner

Get the 2 pin tensioner tool from cam belt tool kit and turn it gently anticlockwise till it hits the stop (ie max tension) then hold and torque bolt to 28 NM and Remove locking tools

place spanner on cam again and this time tighten the Cam torx bolt to 70NM

rotate the engine twice by hand (spanner on crank pulley) this beds in the belt

now loosen off the 13 mm tensioner nut carefully at the same time hold the tensioner with the pin spanner so as not to let fully loose tension and align the tension indicator as below:

tensioner fork highlighted:

this is too slack:

again highlighted (the back fork is to the left of the front fork)

rotate engine again by hand several turns then check indicator is sill showing correct tension and refit timing tools to check timing is spot on and its not jumped a tooth or anything like that

ensure all tools have been removed

REFIT LOWER CAM GUARD NOW or you wont get it back on

next refit lower alternator pulley (ensure dimple lines up with hole in pulley)

at this point its easier to refit and tension the alternator belt as the engine mount isn't on to tension fit new belt then pry back the alternator using a pry bar then do up 3 bolt on alternator the belt should just be able to be rotated about 90 degrees with your fingers...

Now put it all back together

rocker box gasket should be refitted like this

https://www.fiatforum.com/punto-gui...ket-without-having-leak-again-week-later.html

next run a Phonic wheel learn on MES / FES to allow the car to learn the slight change in Cam / Crank position due to the new unstretched belt

and enjoy another 4-5 years motoring...