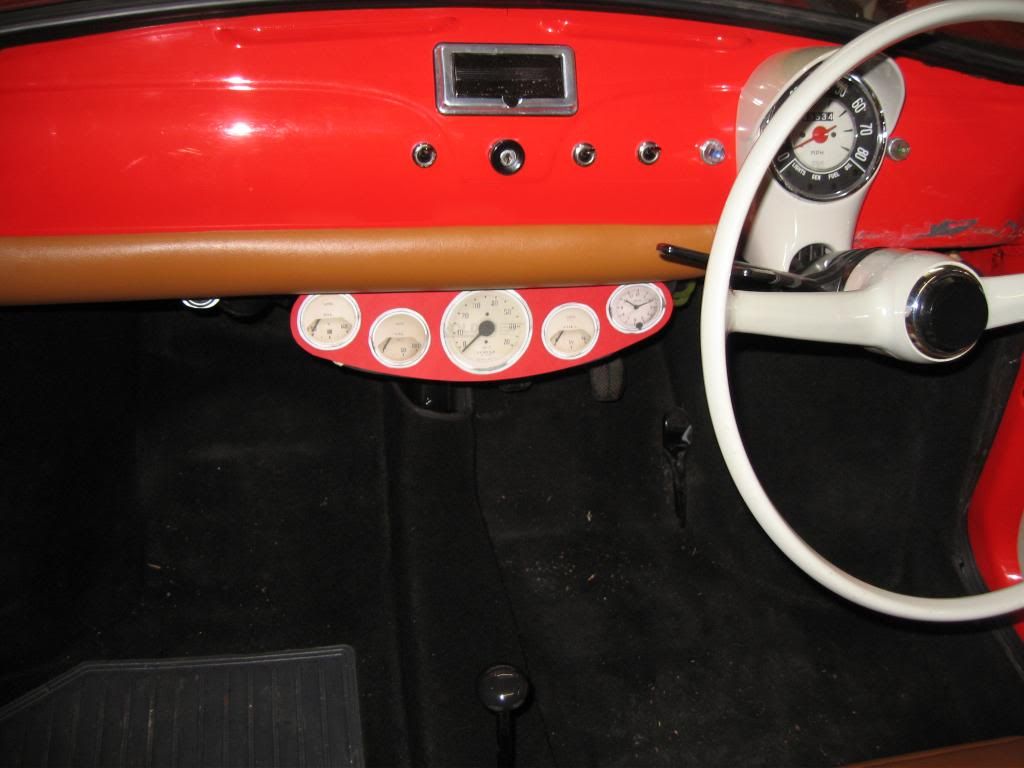

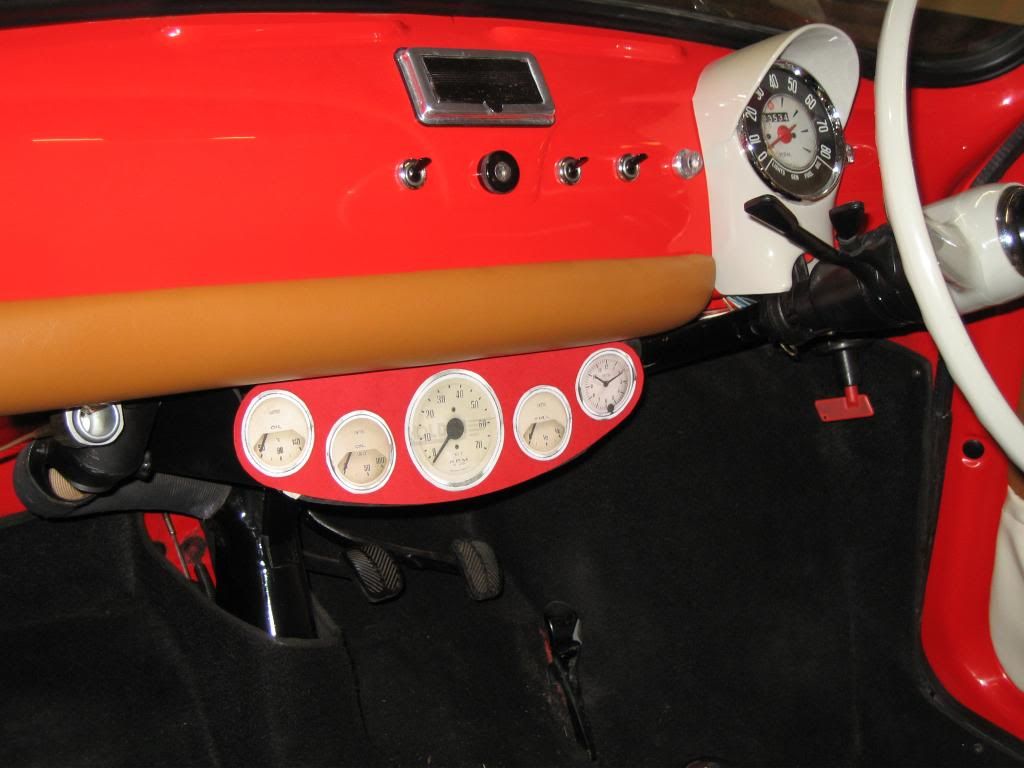

I've mocked up what the panel will look like inserted into the case:

The idea is that the red panel, which houses the gauges, will be made out of steel and sprayed the same colour as the dash. The case (the peach-coloured card) will be made out of either acrylic or steel (whichever seems to be the easiest to fabricate) and then wrapped in foam and vinyl.

I seem to have hit a bit of a snag. I wanted to put the mockup in situ in the car to see how it would look. To do this I needed to remove the glove tray. No problem I thought, it'll be a 10 minute job (experience should have told me it's never a 10 minute job!). I managed to remove the four retaining nuts and washers, even though they were a pig to get to, with the heating ducts and washer button in the way. After removing them, I was hoping I could simply remove the tray. It would appear that the previous owner fitted the tray, then fitted the heating ducts afterwards, as the tray edge is trapped under the heating duct bracket. I decided to loosen the bracket, only to find the nut is buried behind the fuel tank. I also can't move the washer button out of the way as the bracket is attached to the dash behind the knee pad.

It looks like I'll have to do the following:

- move the fuel tank

- slacken the duct bracket

- remove the dash knee pads (I need to fit the other pad, so I'll need to remove the washer arms and motor)

- remove the washer button

- remove the glove tray

Simple really! I guess I know what I'm doing this weekend...

Matt