I have a friend of mine who collects microcars. A couple of years ago he owned a Niki 650 (Fiat 126) which he was going to restore but eventually sold. Last week he discovered a box of 650 engine parts that came with the car in his shed, and knowing my interest in Fiat 500s, he kindly gave them to me. All of the parts were from the same engine, and this poor little motor must have had a hell of a life.

I'm no forensic mechanic, but this is what I found -

At some time in the past someone has dropped a screw into one of the combustion chambers and left it there. The engine has been run with the screw embedding itself repeatedly in the soft alloy roof of the combustion chamber. After cleaning off a lot of carbon, the imprint is so clear that you can measure the pitch of the thread and the length of the screw.

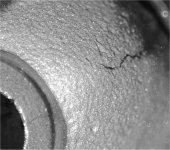

On the same cylinder, the head is cracked near the exhaust and the exhaust valve on that side badly burnt. Maybe the valve was being held open by a screw fragment and cooked itself whilst the engine backfired repeatedly.

Both inlet valves are badly pitted most likely a result of running the engine in a dusty atmosphere without an air filter.

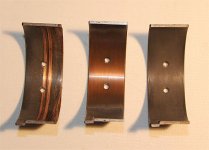

One of the bigend bearing is heavily scored, as is the crank on that side. I guess a piece of that screw fell down there and jammed in the copper/lead babbitt.

The other bigend bearing is heavily pitted. Maybe the oil was full of particulate matter.

The oil pump and oil pickup, as well as the inside of the crankcase, were covered in thick, black muck. The centrifugal oil filter was gummed up with the same stuff. The oil was probably never changed.

Many of the sump screws had been overtightened and stripped the threads in the soft alloy crankcase.

Both piston crowns were thick with carbon and both bores heavily scuffed on one side.

The carby bowl was full of varnish and rust.

This engine had suffered a lot and the remaining parts are completely useless, unless you are looking for a unique boat anchor. None of this is my mates fault - he gave me the parts in good faith, obviously never having inspected them himself.

These motors are tough, resilient and built to work hard. A change of oil, a new air filter and a check on the tappets now and then is usually all it takes to keep them healthy. If there is a moral to this tale of woe, I guess it is that an ounce of prevention is worth ... You know the rest.

I've attached a couple of photos.

Tread your own path,

Chris

I'm no forensic mechanic, but this is what I found -

At some time in the past someone has dropped a screw into one of the combustion chambers and left it there. The engine has been run with the screw embedding itself repeatedly in the soft alloy roof of the combustion chamber. After cleaning off a lot of carbon, the imprint is so clear that you can measure the pitch of the thread and the length of the screw.

On the same cylinder, the head is cracked near the exhaust and the exhaust valve on that side badly burnt. Maybe the valve was being held open by a screw fragment and cooked itself whilst the engine backfired repeatedly.

Both inlet valves are badly pitted most likely a result of running the engine in a dusty atmosphere without an air filter.

One of the bigend bearing is heavily scored, as is the crank on that side. I guess a piece of that screw fell down there and jammed in the copper/lead babbitt.

The other bigend bearing is heavily pitted. Maybe the oil was full of particulate matter.

The oil pump and oil pickup, as well as the inside of the crankcase, were covered in thick, black muck. The centrifugal oil filter was gummed up with the same stuff. The oil was probably never changed.

Many of the sump screws had been overtightened and stripped the threads in the soft alloy crankcase.

Both piston crowns were thick with carbon and both bores heavily scuffed on one side.

The carby bowl was full of varnish and rust.

This engine had suffered a lot and the remaining parts are completely useless, unless you are looking for a unique boat anchor. None of this is my mates fault - he gave me the parts in good faith, obviously never having inspected them himself.

These motors are tough, resilient and built to work hard. A change of oil, a new air filter and a check on the tappets now and then is usually all it takes to keep them healthy. If there is a moral to this tale of woe, I guess it is that an ounce of prevention is worth ... You know the rest.

I've attached a couple of photos.

Tread your own path,

Chris