Introduction

Well guys, i figure with all the questions and advice that i've been badgering you guys about, i'd make a thread about my cinq.

Last year after getting settled in the new house (which has a massive garage), i started looking for something to put in that garage, after getting rid of my old and somewhat failed hobby project, an alfa 33. The reason i didnt do much on the alfa, besides not having a garage for most of the time i had it, was also that i just couldnt think of any fun things to do with it, i briefly entertained the notion of a supercharger, but quickly realized that would be about thirty-three times more advanced than what i could handle.

So after some looking around i decided that a cinq would be a good starter project to cut my teeth on some actual tinkering, since a cinq is relatively simple in terms of technology, and practically every part on it can be upgraded with cheap performance upgrades, up to complete engine swaps.

So after looking at various cinqs and dealing with some rather unscrupulous salesmen, i found this gem:

a '96 sporting with approximately 95K miles on the clock, looking good, save for a blown headgasket. The colourfull floormats with embroided bees on the were a clear tip-off that it had been on shoppig cart duty for its last few years. I had a good look around and found very little rust, just the read bumper support and the back box which had completely lost the end-pipe.

I shook the mans hand for 350 euros (quite a steal i think, since with a fixed head gasket it would have been easily 750 i think), and five days later it was dropped off at my doorstep, so i could put it in the garage.

My plans for the cinq are to make it as close to a racer as i can, while having it road-legal, and usable on the road (so no extremely low drops or slick tires).

My plans:

- replace back box (done)

- strip out interior + rear seats (done)

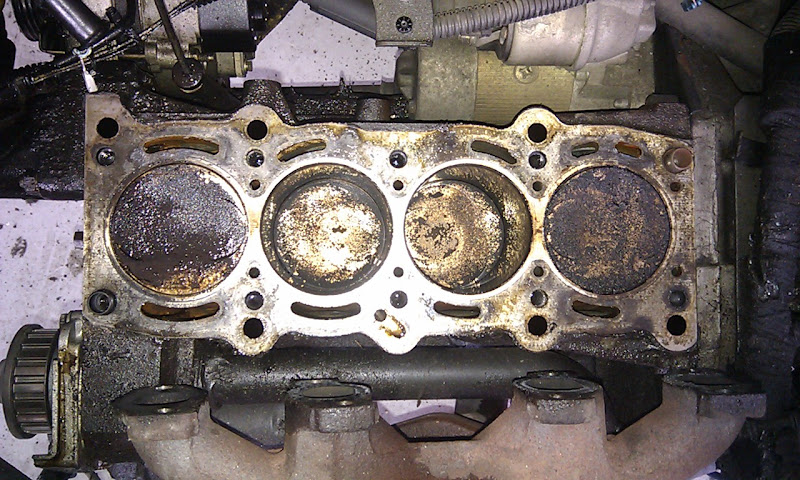

- repair head gasket (doing)

- fit 38 mm TB (on the shelf ready when the head goes back on)

- fit 866 Cam (in the mail as we speak)

- fit open air filter (got a pipercross on the shelf)

- Chip the ecu

- inspect brakes for MOT and if need be replace with upgrades, otherwise upgrades later on

- drop it 30/40 mm, replace shocks as well

- front strut brace

- rear brace between seat mountings (perhaps?)

So that should keep me occupied for a nice while, once i get all that done and my wallet has had time to recover, i have plenty of new plans involving 14" OZ rims, punto GT brakes and engine swapping, but that is all at least a year off currently, first priority is to get it going again and pass MOT, and enjoy the pepped up 1108 over the summer.

I'll leave you guys with a pic of how it is sitting right now:

Last year after getting settled in the new house (which has a massive garage), i started looking for something to put in that garage, after getting rid of my old and somewhat failed hobby project, an alfa 33. The reason i didnt do much on the alfa, besides not having a garage for most of the time i had it, was also that i just couldnt think of any fun things to do with it, i briefly entertained the notion of a supercharger, but quickly realized that would be about thirty-three times more advanced than what i could handle.

So after some looking around i decided that a cinq would be a good starter project to cut my teeth on some actual tinkering, since a cinq is relatively simple in terms of technology, and practically every part on it can be upgraded with cheap performance upgrades, up to complete engine swaps.

So after looking at various cinqs and dealing with some rather unscrupulous salesmen, i found this gem:

a '96 sporting with approximately 95K miles on the clock, looking good, save for a blown headgasket. The colourfull floormats with embroided bees on the were a clear tip-off that it had been on shoppig cart duty for its last few years. I had a good look around and found very little rust, just the read bumper support and the back box which had completely lost the end-pipe.

I shook the mans hand for 350 euros (quite a steal i think, since with a fixed head gasket it would have been easily 750 i think), and five days later it was dropped off at my doorstep, so i could put it in the garage.

My plans for the cinq are to make it as close to a racer as i can, while having it road-legal, and usable on the road (so no extremely low drops or slick tires).

My plans:

- replace back box (done)

- strip out interior + rear seats (done)

- repair head gasket (doing)

- fit 38 mm TB (on the shelf ready when the head goes back on)

- fit 866 Cam (in the mail as we speak)

- fit open air filter (got a pipercross on the shelf)

- Chip the ecu

- inspect brakes for MOT and if need be replace with upgrades, otherwise upgrades later on

- drop it 30/40 mm, replace shocks as well

- front strut brace

- rear brace between seat mountings (perhaps?)

So that should keep me occupied for a nice while, once i get all that done and my wallet has had time to recover, i have plenty of new plans involving 14" OZ rims, punto GT brakes and engine swapping, but that is all at least a year off currently, first priority is to get it going again and pass MOT, and enjoy the pepped up 1108 over the summer.

I'll leave you guys with a pic of how it is sitting right now: