JuliaMS

Member

Hi folks,

I've just finished replacing the glass roof on my 500 and I thought I'd share what I've learnt.

The car had a cracked roof when I bought it (it was the cheapest 500 I could find). In the spirit of cheap motoring I decided to replace the roof myself.

Cheapest eBay roof I could find was shipped attached to the metal frame on a pallet from a breakers yard, this is good in two ways - less chance of breakage during transport and you get to practice removal before starting on the car.

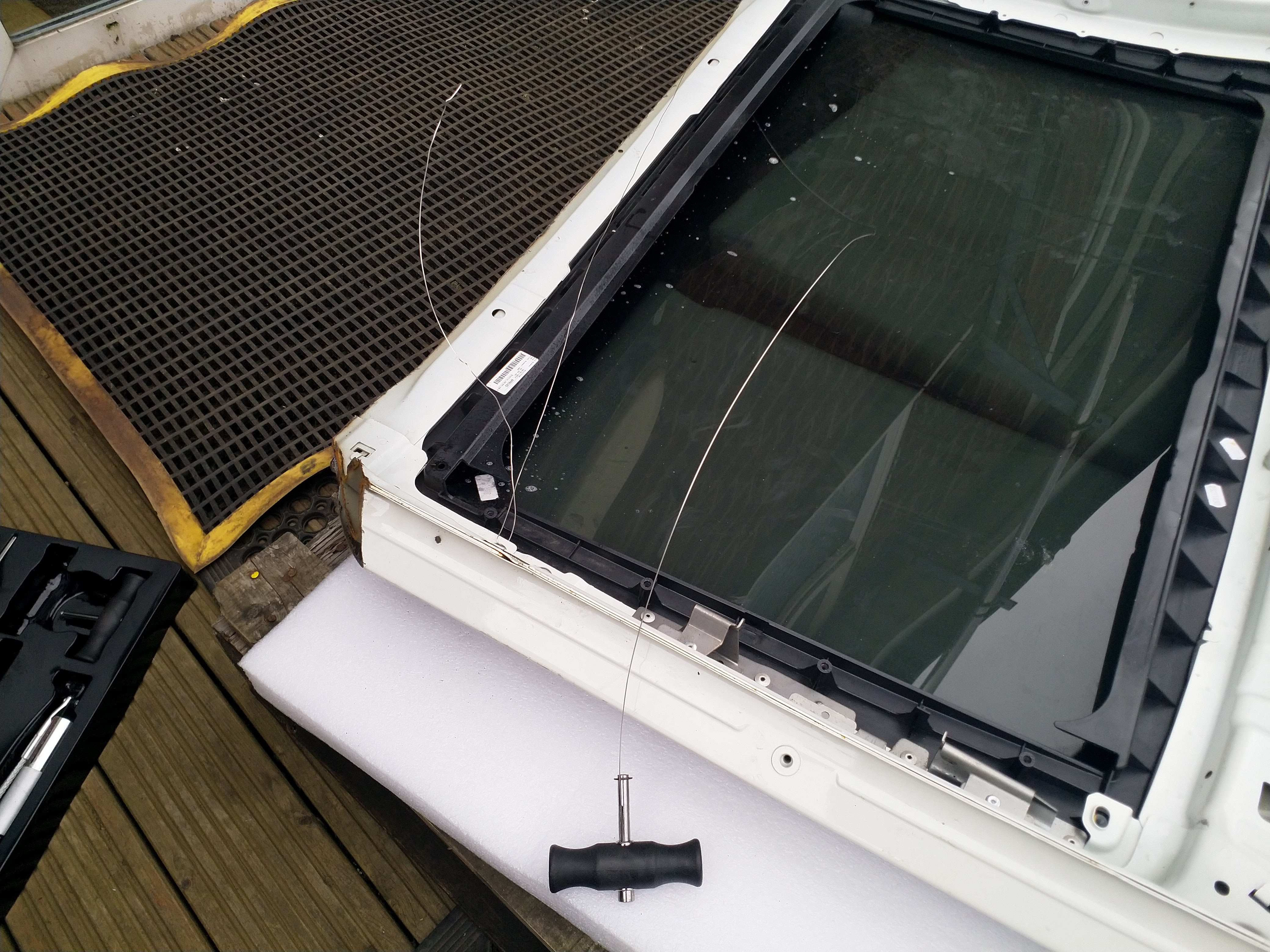

I bought cheap windscreen removal toolkit expecting it to be fairly straightforward to use the "cheesewire" handles to remove the old screen. When this arrived I then proceeded to waste a couple of days trying to remove the new roof....

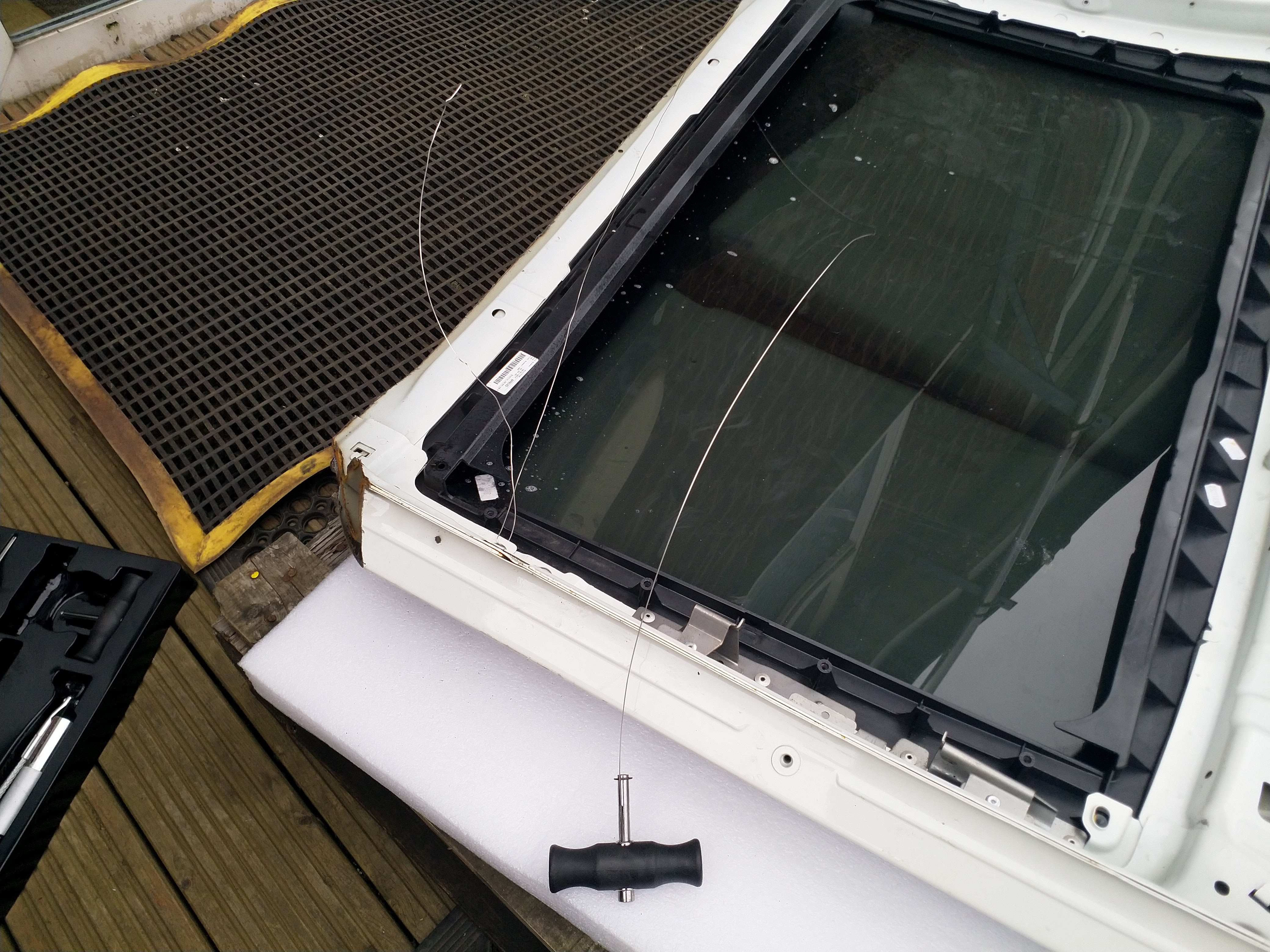

The reason for this is that the plastic surround that the roof is bonded to, has moulded spacers which fix the height of the glass when it is installed. These are tight against the glass and effectively stop the wire.... these are space every two or three inches so you are continually being stopping your tracks.

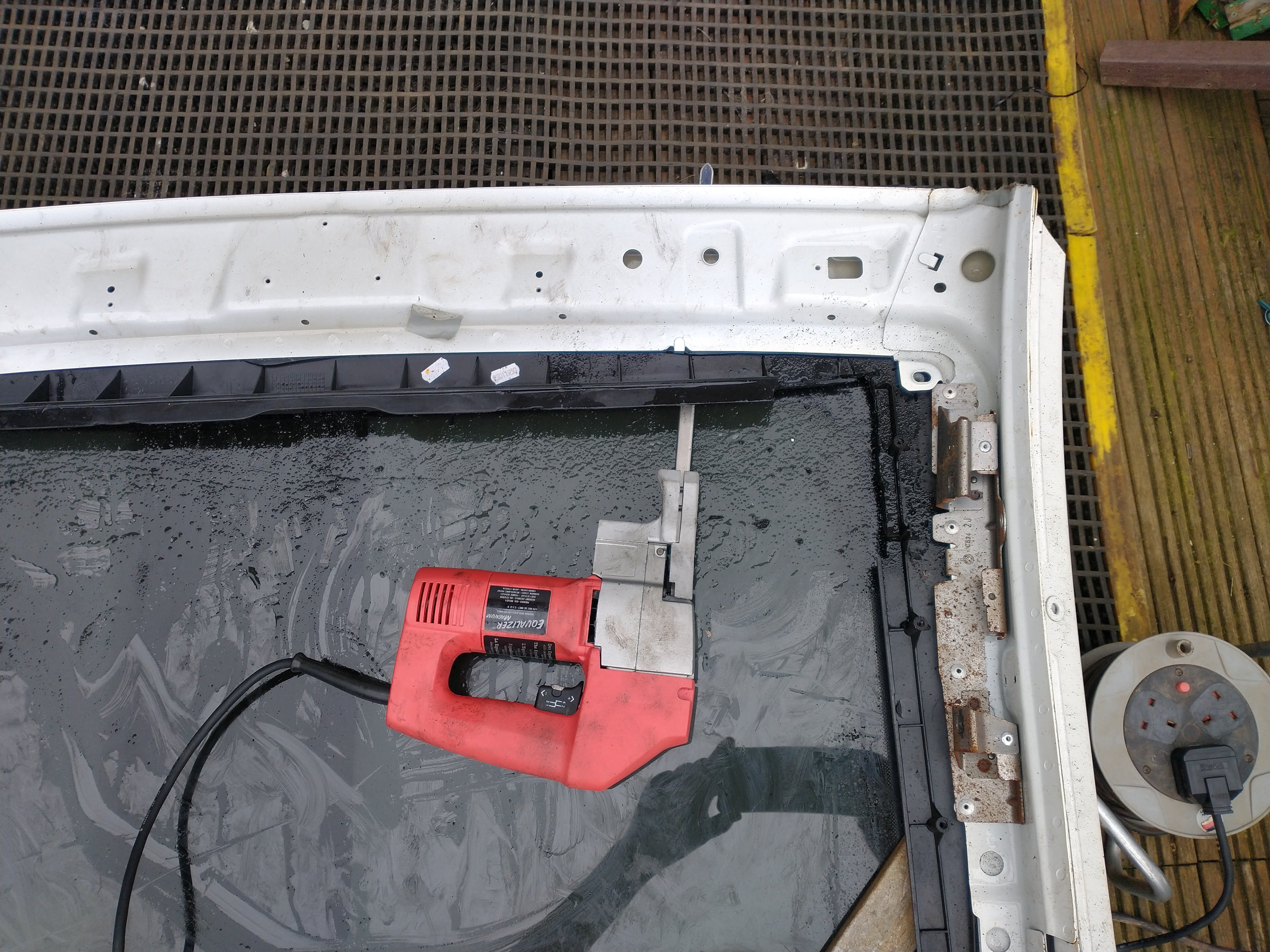

I eventuall ended up resorting to a Fein type oscillating saw it was slow and noisy and only really worked on the back and side edges. The front edge is over 20cm and impossible to reach with the blade.

At this point (last autumn) I gave up!

To be continued.....

I've just finished replacing the glass roof on my 500 and I thought I'd share what I've learnt.

The car had a cracked roof when I bought it (it was the cheapest 500 I could find). In the spirit of cheap motoring I decided to replace the roof myself.

Cheapest eBay roof I could find was shipped attached to the metal frame on a pallet from a breakers yard, this is good in two ways - less chance of breakage during transport and you get to practice removal before starting on the car.

I bought cheap windscreen removal toolkit expecting it to be fairly straightforward to use the "cheesewire" handles to remove the old screen. When this arrived I then proceeded to waste a couple of days trying to remove the new roof....

The reason for this is that the plastic surround that the roof is bonded to, has moulded spacers which fix the height of the glass when it is installed. These are tight against the glass and effectively stop the wire.... these are space every two or three inches so you are continually being stopping your tracks.

I eventuall ended up resorting to a Fein type oscillating saw it was slow and noisy and only really worked on the back and side edges. The front edge is over 20cm and impossible to reach with the blade.

At this point (last autumn) I gave up!

To be continued.....

Last edited: