Hi there

I would like to introduce my NEW Cinque

Engine:

1242 cc Punto 75

MPi intake

MPi injectors

palio intake cover

284°custom Camshaft - 10.5mm stroke

lowered head - 0,9mm

lowered profile of cylinder head valves

polished head valves upper part

bigger exhaust holes in head

1,2 16V clutch

6 speed gearbox from Punto 55S

Custom made ECU upgrade.

Rev Limiter moved to 7600, more fuel from 3500rpm up to 130% on rev limiter.

I haven´t finished yet, I am expecting finish approx in 1 month

some photos and comments -

http://italiancars.org/fiat/diskuze/index.php?msg_group=5&action=show&id=173040

I would like to introduce my NEW Cinque

Engine:

1242 cc Punto 75

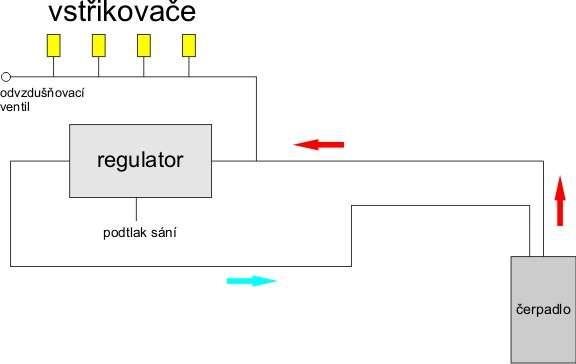

MPi intake

MPi injectors

palio intake cover

284°custom Camshaft - 10.5mm stroke

lowered head - 0,9mm

lowered profile of cylinder head valves

polished head valves upper part

bigger exhaust holes in head

1,2 16V clutch

6 speed gearbox from Punto 55S

Custom made ECU upgrade.

Rev Limiter moved to 7600, more fuel from 3500rpm up to 130% on rev limiter.

I haven´t finished yet, I am expecting finish approx in 1 month

some photos and comments -

http://italiancars.org/fiat/diskuze/index.php?msg_group=5&action=show&id=173040