....guide on the Panda? preferably picture rich.

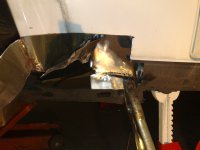

I made a start on mine yesterday, its the only structural rust on the car.

Its gone at the back on the OS sill, but its gone through the inner & outer sill & the bottom of the inner & outer arch.

Its quite a complex combination of shaped panels for such a basic car, more complex than the Uno for example, & I`ve got no pictures to go by. Eper isnt detailed enough. I can obviously see the outer panels on the NS, but not the internal ones!

I did do a search but cant find pics, so I`m hoping someone can point me in the right direction

1.

2.

3.

4.

5.

I made a start on mine yesterday, its the only structural rust on the car.

Its gone at the back on the OS sill, but its gone through the inner & outer sill & the bottom of the inner & outer arch.

Its quite a complex combination of shaped panels for such a basic car, more complex than the Uno for example, & I`ve got no pictures to go by. Eper isnt detailed enough. I can obviously see the outer panels on the NS, but not the internal ones!

I did do a search but cant find pics, so I`m hoping someone can point me in the right direction

1.

2.

3.

4.

5.

Last edited: