- Joined

- Sep 7, 2010

- Messages

- 2,388

- Points

- 468

I have read about this issue in a few posts now: if one handbrake cable snaps, the other might stretch so it is worth changing it too.

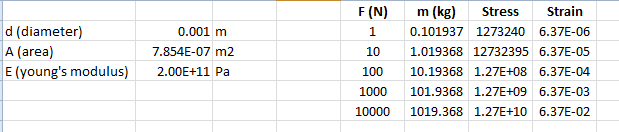

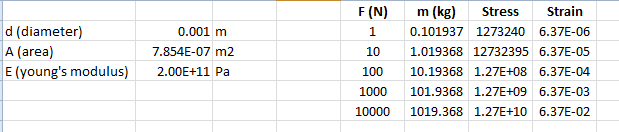

I have done a quick calculation to see if this is true:

This shows that for a 1mm diameter steel wire, you would need to supply a tensile load of 1000N (appromately 100kg equivalent) in order to stretch the wire by 0.6%. For a handbrake cable of 1m length, this is a 6mm stretch.

For several reasons, I think that the cable does not stretch:

1. A typical cable is much bigger than 1mm

2. I doubt the handbrake applies 100kg load to the cable

3. The plastic deformation point onset is something like 1/2 tonne of load, for a 1mm wire! In other words, any extension actually achieved would be a reversible extension, rather than an irreversible stretch.

The better reason to switch a second cable is that the cross sectional area is likely to me tiny due to corrosion. This results in the ultimate strength of the cable being achieved by the handbreak, and ping!

Anyway, that's the theory....how about the practice?

I have done a quick calculation to see if this is true:

This shows that for a 1mm diameter steel wire, you would need to supply a tensile load of 1000N (appromately 100kg equivalent) in order to stretch the wire by 0.6%. For a handbrake cable of 1m length, this is a 6mm stretch.

For several reasons, I think that the cable does not stretch:

1. A typical cable is much bigger than 1mm

2. I doubt the handbrake applies 100kg load to the cable

3. The plastic deformation point onset is something like 1/2 tonne of load, for a 1mm wire! In other words, any extension actually achieved would be a reversible extension, rather than an irreversible stretch.

The better reason to switch a second cable is that the cross sectional area is likely to me tiny due to corrosion. This results in the ultimate strength of the cable being achieved by the handbreak, and ping!

Anyway, that's the theory....how about the practice?