Rodney 2000

Member

Hi all,

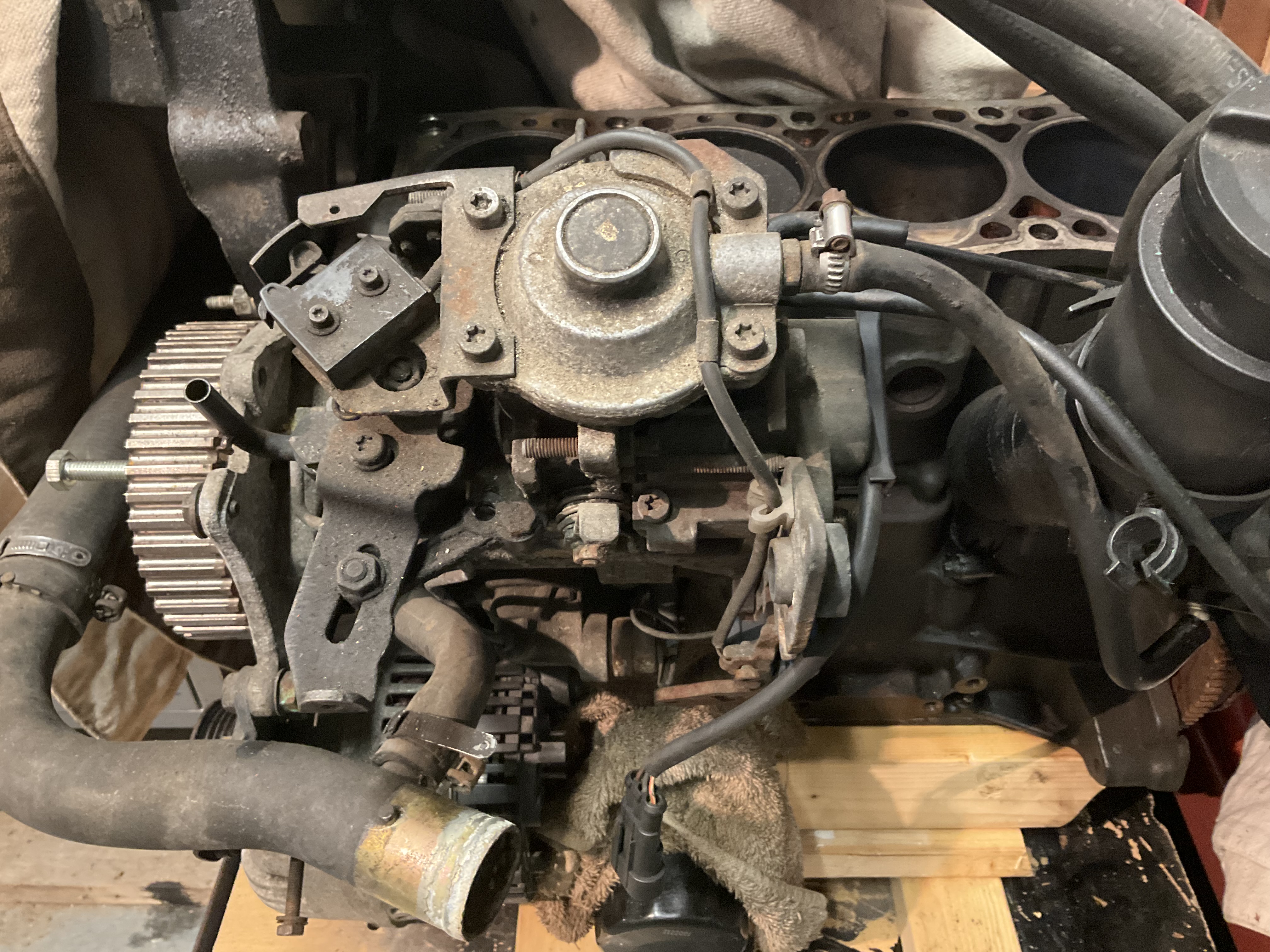

I could do with some help again please. I have recently fitted a replacement engine in my 2000 fiat Ducato motor home….bent Conrod in the last engine made replacing it a quicker option. Engine has gone in well…all plumbed and wired in. Replacement engine has only 20000 in the clock and is exactly the same as removed one however the engine turns over but will not fire…I am aware I may well have air in the fuel lines etc but am really struggling to remove it. I’ve cracked injectors when turning over but am not getting any fuel, I’m aware that there may be other faults such as immobiliser interference etc but I’m stuck as to what to do next. Is there a way of bleeding the fuel system….some forum post mention bleed screws and hand pumps (I have not been able to find these). Is there a way to check the fuel pump is working etc? Hoping you guys can help me with next steps…..thanks in advance, (picture of fuel pump type attached)

I could do with some help again please. I have recently fitted a replacement engine in my 2000 fiat Ducato motor home….bent Conrod in the last engine made replacing it a quicker option. Engine has gone in well…all plumbed and wired in. Replacement engine has only 20000 in the clock and is exactly the same as removed one however the engine turns over but will not fire…I am aware I may well have air in the fuel lines etc but am really struggling to remove it. I’ve cracked injectors when turning over but am not getting any fuel, I’m aware that there may be other faults such as immobiliser interference etc but I’m stuck as to what to do next. Is there a way of bleeding the fuel system….some forum post mention bleed screws and hand pumps (I have not been able to find these). Is there a way to check the fuel pump is working etc? Hoping you guys can help me with next steps…..thanks in advance, (picture of fuel pump type attached)