I decided to write this guide to help with Dualogic gearbox problems after seeing a Brazilian mechanic that has a youtube channel and deals with Dualogic gearbox repairs. He channel is very popular (search Motortech dualogic) and has even had clients transport their cars from Sao Paulo all the way to his garage (over 1500km). He says that many garages have no idea on how to repair these gearboxes. They damage components or install them wrongly and just lie to their customers.

He also says in that all the gear boxes he has repaired he has never once had to change a gearbox ECU even when customers brought the cars and said that the diagnostic software shows a DTC error as the ECU being damaged. His basic guide on how to trouble shoot and repair is the following:

Do a visual exam looking for leaks broken wires on the gearbox.

Connect the diagnostic software,

Check for error codes (though he has had cases where the gearbox had a problem but no error codes)

Check the system pressure by selecting 1 gear, R and Neutral the pressure should not drop below 36 and should immediately pressurize to 46/48 bar then drop slowing to 38 before the electric motor kicks in. Switch off engine the pressure should remain steady and drop only 2-3 bars.

(The system works with a line pressure ranging from 36.5 to 46 bars (on some models 48 bars) under normal conditions. In Recovery mode, the system will perform to its best at a pressure of 75 bars. The electric pump is turned on when the pressure drops below 36.5 bars and off when the pressure in the circuit reaches 46 bars.)

Next check the clutch degradation index , This can tell us if the clutch needs to be changed. Usually a value above 6000 means the clutch is worn. This valve should not be trusted 100% unless you have been the only owner and know when the clutch was changed and that no one has reset this value.

He then disassembles the whole robot cleans all the parts very well changes worn o rings. Checks sensors and Solenoid Valves.

One very important check is to make sure that when the robot unit is removed you can manually select and engage the gears. If you cannot then the robot will also not be able. The gearbox will then have to be repaired.

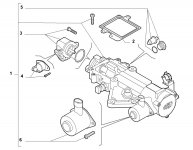

90 of the time he also removes the clutch to check the condition and also the condition of the clutch position sensor to check for leaks (this depends of the type of robot as some units like CFC300 have the clutch position sensor on the Clutch actuator inside the gearbox and other have the sensor on the - Master-Slave system.

In Master-Slave system hydraulic fluid pushes a piston which then push DOT4 brake fluid which in turn pushes the CSC (Clutch slave cylinder) actuator inside the gearbox. The clutch position sensor is incorporated into the Master-Slave system

In the other system hydraulic fluid pushes the CSC (Clutch slave cylinder) actuator directly. The clutch position sensor is incorporated into the CSC.

He then refits everything and calibrates the system.

SELF-ADJUSTMENTS

As follows:

• Clutch bleeding (check oil level)

• End of line/service self-adjustment (check oil level)

• Clutch self-adjustment (kiss point)

• Clutch wear index calculation

The best place to have the gearbox fixed would be an automatic gearbox specialist. They have experience in dissembling and cleaning automatic transmission valve bodies (which the Solenoid Valve Unit is very similar.

First you should download the service manual to have an understanding of how the gear box works. Search for M20 Dualogic gearbox and M40 Dualogic. The difference between these 2 is that the M20 has the gearbox Ecu bolted onto the Solenoid Valve Unit. To accesses the electro valves or change the pressure sensor the ecu must be pulled out, using a pluller.

These are the problems that can go wrong and how to check them.

Gear box errors

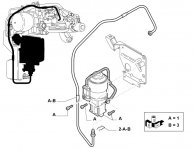

Power unit (Pump).

Hydraulic tank: Is their fluid inside? Is it broken or cracked, Are the rubber hoses in good condition no holes cuts.

Electric motor: Does the electric motor run when the door is open, Are there any oil leaks between the motor and pump. (seal condition?)You can also check that the motor runs using diagnostic software,

Accumulator: The only way to check the accumulator is to depressurize the system and remove it, then weight it. It should weight around 600g to 700g more than this and it has a leak inside

One way valve and filter: Only way to check is disassembly the valve and check. Fiat does not sell the valve, You have to buy the whole power unit body.

(one some models the accumulator is located on the solenoid valve unit)

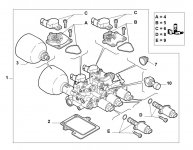

Solenoid Valve Unit

Solenoid valve.: Are the valves working, using the diag, software you can check each valve by listing. Any leaks. 90% percent of the internals leaks that the Brazilian garage has is with the selector rod leaking. The seals go and fluid ends up damaging the position sensor. The whole unit has to be disassembled cleaned very well and new o rings fitted.

Gear shifter

The Selected gear must be the same as the one that has been selected by the Solenoid Valve Unit. This means the the gearbox ECU must also see what gear you have selected you can test this using the diagnostic software. The gear selector use hall effect sensor and also a and small micro controller.

Cables and Input sensors signals

Check cabling and earth point no broken cables

Check if you can get a reading from all of these sensor using diag software some time just one broken sensor and the car will not even start or the gearbox won’t work correctly

Input signals

For logical operations, the system must use the following incoming signals from other systems of the vehicle:

• Clutch revolution sensor (the value is read from the primary shaft of the gearbox)

• Number of engine revolutions - Crankshaft sensor (incoming signal from the engine control unit via the C-CAN

network).

• Brake pedal switch (two signals: one separate - pin 9 of vehicle connector, the other via the CCAN network).

• Accelerator pedal position.

• Vehicle speed (abs wheel speed sensors)

• Engine temperature and outside temperture sensor )used to calculate the oil temp, and also clucth temp.

Specific sensors of the automated gearbox

• Position sensor for: clutch, engagement and selection.

• Position sensor for gear engagement position

• Position sensor for gear selection position.

• Line pressure sensor

For example, to check whether clutch is slipping (for a Selespeed ECU) move "Engine rpm" and "Clutch disk speed" meters to the same tab, activate and zoom them, start scan and drive the car for some time. If the clutch speed is lower than engine speed for non-idle, the clutch might be slipping and considered for replacement.

Here is a trouble shooting guide I found on the internet for the Ferrari F1 system it is based on the sleespeed system. (It was in German, so I tried to translate the best I could) They also say that the best oil to use in the system is total synthetic hydraulic oil like Liqui Moly Central Hydraulic Oil. He says that Automatic transmission fluid (like tutela cs selespeed oil which is a Synthetic Dexron 3 type auto fluid) is not the right one because the system has no gears and is purely an hydraulic system were as ATf fulid is made to also lubricate gears.

Flashing gear indicator / gears can be skipped with a sense of delay arises

Is ALWAYS a sensor failure!

Most sensor gear selector or gear position (switch-on sensor or sensor choice)

in rare cases, a failure of the clutch position sensor

is often also the multipolar connector is damaged (Contact Care?)

Gears are ejected in Driving

Accumulator defective

Too little oil in the system

Hydraulic pump runs only briefly at

Accumulator defective

Pump relay defective (rare)

"Pump relay is jammed" error stored in ECU

Accumulator defective

Pump relay defective (rare)

No shift possible / Gearbox stuck in "N" and blocked

Hydraulic pump defective

Pump relay defective

Gearbox defective (very rarely)

Gear selecting is not possible via shift selector lever but is possible using diagnostic software.

Shift / selector lever defective (check connector)

often error stored in the system -> "switch lever X" (X = number)

Pump runs constantly (open loop)

Pressure sensor defective

Starting almost impossible - chatter clutch - only in high speeds approachable

EV0 defective valve of the clutch control

old oil in the system -> COMPLETE SWAP!

Air in the system

System turns off unexpectedly (even when parked ignition)

Accumulator defective

A defect of the pressure accumulator draws in most cases, as a result of error, a defective hydraulic pump itself!

Accumulator defects are "creeping" defects which are noticed by the user until it is too late.

To prevent mistakes ....

Change it at least every 20Tkm the hydraulic oil in the circuit

Maintain regularly all contacts / connector on the F1 / Selespeed

swap them the gear oil (according to the manufacturer), or at the latest after 60Tkm

let them calibrate their F1 system regularly

make it the type of oil in the F1 system "Liqui Moly Central Hydraulic Oil" to

How this can maybe help someone.

He also says in that all the gear boxes he has repaired he has never once had to change a gearbox ECU even when customers brought the cars and said that the diagnostic software shows a DTC error as the ECU being damaged. His basic guide on how to trouble shoot and repair is the following:

Do a visual exam looking for leaks broken wires on the gearbox.

Connect the diagnostic software,

Check for error codes (though he has had cases where the gearbox had a problem but no error codes)

Check the system pressure by selecting 1 gear, R and Neutral the pressure should not drop below 36 and should immediately pressurize to 46/48 bar then drop slowing to 38 before the electric motor kicks in. Switch off engine the pressure should remain steady and drop only 2-3 bars.

(The system works with a line pressure ranging from 36.5 to 46 bars (on some models 48 bars) under normal conditions. In Recovery mode, the system will perform to its best at a pressure of 75 bars. The electric pump is turned on when the pressure drops below 36.5 bars and off when the pressure in the circuit reaches 46 bars.)

Next check the clutch degradation index , This can tell us if the clutch needs to be changed. Usually a value above 6000 means the clutch is worn. This valve should not be trusted 100% unless you have been the only owner and know when the clutch was changed and that no one has reset this value.

He then disassembles the whole robot cleans all the parts very well changes worn o rings. Checks sensors and Solenoid Valves.

One very important check is to make sure that when the robot unit is removed you can manually select and engage the gears. If you cannot then the robot will also not be able. The gearbox will then have to be repaired.

90 of the time he also removes the clutch to check the condition and also the condition of the clutch position sensor to check for leaks (this depends of the type of robot as some units like CFC300 have the clutch position sensor on the Clutch actuator inside the gearbox and other have the sensor on the - Master-Slave system.

In Master-Slave system hydraulic fluid pushes a piston which then push DOT4 brake fluid which in turn pushes the CSC (Clutch slave cylinder) actuator inside the gearbox. The clutch position sensor is incorporated into the Master-Slave system

In the other system hydraulic fluid pushes the CSC (Clutch slave cylinder) actuator directly. The clutch position sensor is incorporated into the CSC.

He then refits everything and calibrates the system.

SELF-ADJUSTMENTS

As follows:

• Clutch bleeding (check oil level)

• End of line/service self-adjustment (check oil level)

• Clutch self-adjustment (kiss point)

• Clutch wear index calculation

The best place to have the gearbox fixed would be an automatic gearbox specialist. They have experience in dissembling and cleaning automatic transmission valve bodies (which the Solenoid Valve Unit is very similar.

First you should download the service manual to have an understanding of how the gear box works. Search for M20 Dualogic gearbox and M40 Dualogic. The difference between these 2 is that the M20 has the gearbox Ecu bolted onto the Solenoid Valve Unit. To accesses the electro valves or change the pressure sensor the ecu must be pulled out, using a pluller.

These are the problems that can go wrong and how to check them.

Gear box errors

Power unit (Pump).

Hydraulic tank: Is their fluid inside? Is it broken or cracked, Are the rubber hoses in good condition no holes cuts.

Electric motor: Does the electric motor run when the door is open, Are there any oil leaks between the motor and pump. (seal condition?)You can also check that the motor runs using diagnostic software,

Accumulator: The only way to check the accumulator is to depressurize the system and remove it, then weight it. It should weight around 600g to 700g more than this and it has a leak inside

One way valve and filter: Only way to check is disassembly the valve and check. Fiat does not sell the valve, You have to buy the whole power unit body.

(one some models the accumulator is located on the solenoid valve unit)

Solenoid Valve Unit

Solenoid valve.: Are the valves working, using the diag, software you can check each valve by listing. Any leaks. 90% percent of the internals leaks that the Brazilian garage has is with the selector rod leaking. The seals go and fluid ends up damaging the position sensor. The whole unit has to be disassembled cleaned very well and new o rings fitted.

Gear shifter

The Selected gear must be the same as the one that has been selected by the Solenoid Valve Unit. This means the the gearbox ECU must also see what gear you have selected you can test this using the diagnostic software. The gear selector use hall effect sensor and also a and small micro controller.

Cables and Input sensors signals

Check cabling and earth point no broken cables

Check if you can get a reading from all of these sensor using diag software some time just one broken sensor and the car will not even start or the gearbox won’t work correctly

Input signals

For logical operations, the system must use the following incoming signals from other systems of the vehicle:

• Clutch revolution sensor (the value is read from the primary shaft of the gearbox)

• Number of engine revolutions - Crankshaft sensor (incoming signal from the engine control unit via the C-CAN

network).

• Brake pedal switch (two signals: one separate - pin 9 of vehicle connector, the other via the CCAN network).

• Accelerator pedal position.

• Vehicle speed (abs wheel speed sensors)

• Engine temperature and outside temperture sensor )used to calculate the oil temp, and also clucth temp.

Specific sensors of the automated gearbox

• Position sensor for: clutch, engagement and selection.

• Position sensor for gear engagement position

• Position sensor for gear selection position.

• Line pressure sensor

For example, to check whether clutch is slipping (for a Selespeed ECU) move "Engine rpm" and "Clutch disk speed" meters to the same tab, activate and zoom them, start scan and drive the car for some time. If the clutch speed is lower than engine speed for non-idle, the clutch might be slipping and considered for replacement.

Here is a trouble shooting guide I found on the internet for the Ferrari F1 system it is based on the sleespeed system. (It was in German, so I tried to translate the best I could) They also say that the best oil to use in the system is total synthetic hydraulic oil like Liqui Moly Central Hydraulic Oil. He says that Automatic transmission fluid (like tutela cs selespeed oil which is a Synthetic Dexron 3 type auto fluid) is not the right one because the system has no gears and is purely an hydraulic system were as ATf fulid is made to also lubricate gears.

Flashing gear indicator / gears can be skipped with a sense of delay arises

Is ALWAYS a sensor failure!

Most sensor gear selector or gear position (switch-on sensor or sensor choice)

in rare cases, a failure of the clutch position sensor

is often also the multipolar connector is damaged (Contact Care?)

Gears are ejected in Driving

Accumulator defective

Too little oil in the system

Hydraulic pump runs only briefly at

Accumulator defective

Pump relay defective (rare)

"Pump relay is jammed" error stored in ECU

Accumulator defective

Pump relay defective (rare)

No shift possible / Gearbox stuck in "N" and blocked

Hydraulic pump defective

Pump relay defective

Gearbox defective (very rarely)

Gear selecting is not possible via shift selector lever but is possible using diagnostic software.

Shift / selector lever defective (check connector)

often error stored in the system -> "switch lever X" (X = number)

Pump runs constantly (open loop)

Pressure sensor defective

Starting almost impossible - chatter clutch - only in high speeds approachable

EV0 defective valve of the clutch control

old oil in the system -> COMPLETE SWAP!

Air in the system

System turns off unexpectedly (even when parked ignition)

Accumulator defective

A defect of the pressure accumulator draws in most cases, as a result of error, a defective hydraulic pump itself!

Accumulator defects are "creeping" defects which are noticed by the user until it is too late.

To prevent mistakes ....

Change it at least every 20Tkm the hydraulic oil in the circuit

Maintain regularly all contacts / connector on the F1 / Selespeed

swap them the gear oil (according to the manufacturer), or at the latest after 60Tkm

let them calibrate their F1 system regularly

make it the type of oil in the F1 system "Liqui Moly Central Hydraulic Oil" to

How this can maybe help someone.