jolly500

Member

Hi all,

I'm busy putting together a 650cc engine for the first time. I had the crank 'main' journals measured as standard. I've installed the crank with new standard main bearings at both ends and it turns perfectly.

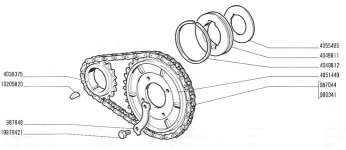

I've installed the camshaft and the timing gear (including the 2 'spacers') and the crank still turns smoothly.

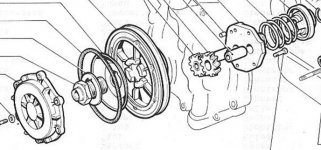

I've now put on the timing gear cover, the crank pulley and the oil thrower device and when I tighted the big hollow bolt on to the end (to 150nm) the crank is extremely stiff to turn.

Where am I going wrong?

Thanks

Steve

I'm busy putting together a 650cc engine for the first time. I had the crank 'main' journals measured as standard. I've installed the crank with new standard main bearings at both ends and it turns perfectly.

I've installed the camshaft and the timing gear (including the 2 'spacers') and the crank still turns smoothly.

I've now put on the timing gear cover, the crank pulley and the oil thrower device and when I tighted the big hollow bolt on to the end (to 150nm) the crank is extremely stiff to turn.

Where am I going wrong?

Thanks

Steve

Last edited: