Hi,

I wanted to bleed my clutch today as getting into first gear needs some patience if the car is standing. I already bled my brakes.

Now, to get to the clutch bleed valve on the Abarth Punto Evo, it really isn't easy as there's the battery, the battery tray, the radiator hose and some air conduit which all impede access.

I removed the battery and battery tray and undid the upper connection of that air hose. After lots of fiddling, I managed to remove the cap of the nipple (which resulted in loosing it in the abys of the engine bay), and I managed to put the collector hose of the receiving bleed fluid bottle on the nipple. A lot of force and patience was needed to move the clip of the bleed valve upwards. It finally clicked in position.

However, there was no way to pull the hydraulic hose ("the operating cylinder supply hose") rightwards out of the plastic bleed valve as I was supposed to do: it is corroded in place. Over a period of 20 minutes, I repeately applied some rust remover spray and pulled and twisted, to no avail. Pulling hard or trying to twist the metal part of the hose by hand would rather pull the entire tubing out of the clutch rather than open the bleed valve. I had a pressure tool connected, with 1 bar of pressure, but nothing came out of the nipple. I tried prying the connecting hose away from the plastic bleed valve casing using a flat screwdriver, but this would only dent the plastic casing.

So, conclusion: the bleed valve of the clutch is corroded and won't budge even if great force is used (using one hand and twisting, or plyers, not enough space to use two plyers or two hands).

By the way, I wasn't able to push the clip back in, even with force, it was now totally stuck in the open position.

What should be done next, can the bleed valve of the clutch be remplaced? How to go about it? The access is so difficult, looks like a lot of other stuff needs to be removed in order to gain access. Like the front bumper and the radiator? I'm not sure about doing this myself.

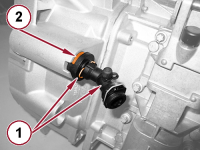

See images: I'm talking about the clip distant from the clutch (the 2nd clip on the right from the nipple), where the connecting hose inserts into the plastic bleed valve casing. (1) in the image "clutch connecting hose", this black part is stuck and won't move outwards to the right after raising the clip.

It's also called a "three-way connector"

I wanted to bleed my clutch today as getting into first gear needs some patience if the car is standing. I already bled my brakes.

Now, to get to the clutch bleed valve on the Abarth Punto Evo, it really isn't easy as there's the battery, the battery tray, the radiator hose and some air conduit which all impede access.

I removed the battery and battery tray and undid the upper connection of that air hose. After lots of fiddling, I managed to remove the cap of the nipple (which resulted in loosing it in the abys of the engine bay), and I managed to put the collector hose of the receiving bleed fluid bottle on the nipple. A lot of force and patience was needed to move the clip of the bleed valve upwards. It finally clicked in position.

However, there was no way to pull the hydraulic hose ("the operating cylinder supply hose") rightwards out of the plastic bleed valve as I was supposed to do: it is corroded in place. Over a period of 20 minutes, I repeately applied some rust remover spray and pulled and twisted, to no avail. Pulling hard or trying to twist the metal part of the hose by hand would rather pull the entire tubing out of the clutch rather than open the bleed valve. I had a pressure tool connected, with 1 bar of pressure, but nothing came out of the nipple. I tried prying the connecting hose away from the plastic bleed valve casing using a flat screwdriver, but this would only dent the plastic casing.

So, conclusion: the bleed valve of the clutch is corroded and won't budge even if great force is used (using one hand and twisting, or plyers, not enough space to use two plyers or two hands).

By the way, I wasn't able to push the clip back in, even with force, it was now totally stuck in the open position.

What should be done next, can the bleed valve of the clutch be remplaced? How to go about it? The access is so difficult, looks like a lot of other stuff needs to be removed in order to gain access. Like the front bumper and the radiator? I'm not sure about doing this myself.

See images: I'm talking about the clip distant from the clutch (the 2nd clip on the right from the nipple), where the connecting hose inserts into the plastic bleed valve casing. (1) in the image "clutch connecting hose", this black part is stuck and won't move outwards to the right after raising the clip.

It's also called a "three-way connector"

- Model

- Abarth Punto Evo

- Year

- 2010

Attachments

Last edited: