Ok, I obviously owe you all an update and I have made some progress and a discovery of a new symptom. However, I will lay out what I did in the order I did it, just in case there are useful bits in there somewhere that I do not understand the significance of.

1) Error Code Check:

The error code was back, this specific error code has been recurring. I have had it appear every now and then over the past 7 odd years. I saved the diagnostic report with freeze frames if that means anything to anyone.

2) ECU Connector Clean:

Decided to remove the two ECU connectors and spray some contact cleaner on them. Then I reassembled them. They looked fine.

3) Blocked the Exhaust:

I blocked the exhaust with the engine running and no pressure was built up. The silencer weld to the pipe running the length of the car is gone and it is leaking heavily. This is currently an advisory from an MOT 6 months ago. I check near the CAT whilst running and blocking and did not notice/hear a leak in that space (the one at the silencer was obvious).

4) Check Battery Voltage:

On the OBDII reader the voltage read was varying a lot from 13.5 V to 14.2 V (during idling - with no additional accessories on, e.g., radio, cabin fan, etc.). Not sure how much I believe it. The battery is new (like two weeks old) - Bosch S4 Car Battery 202. I will throw a multimeter on it to check later.

5) Look at Fuel and Coolant Data:

I had a look at Coolant and Fuel trim data but did not see anything with this that stood out to me. For the fuel system I could only find trim data.

Also had a drive where I checked coolant temperature as well. Looked ok. I was messing around at the start, then idled until ~1000 and drove between 1000 and 2200ish and then idled again until the end.

6) Check for Vacuum Leaks:

I carefully blocked the smaller inlet on the throttle body that goes to the idle control valve. The engine struggled, but stayed alive with the engine idle holding at ~500 RPM. The graph shows the two time I blocked it. This made me think that a vacuum leak might be present.

However, I then blocked both throttle body inlets (to the butterfly valve and the idle control valve) and the engine died very quickly (see plot below). Though the butterfly valve appeared well seated there was clearly a leak flow around it. Pretty sure this should not affect idle though as it is all before the MAP. I then blocked the butterfly valve inlet, leaving only the idle control valve inlet open and it made no difference. Just a double check that it was not affecting idle.

7) Revert to old Throttle Body:

In this I wanted to see what would happen if I put the old Throttle Body back on. Why? In changing the throttle body originally it did not make a difference, then I changed other things (like lambda and map sensors) so I switched it back just to see. What happened? Perfect warm engine idle, holding a solid 800ish RPM.

New Throttle Body – Directly Before Swap:

Old Throttle Body – Directly After Swap:

Note this is holding a steady 800ish RPM as expected!

Old Throttle Body – Directly After Swap (repeat of the previous one - to check was it a fluke):

Note this is holding a steady 800ish RPM as expected as before. However, this time there is a little spike in the intake manifold pressure between ~120-160 and again between ~310-340. These both coincide with where the engine radiator fan has kicked in. The car felt great after this but again it did not hold and high idle emerged again.

8) Major Discovery - Idle Affected by Electrical Load:

Shortly after my perfect new idle (from point 7 above) I drove to pick up one of my kids. I parked up and switched off the main lights - and the engine reved!

I had not seen/noticed this behaviour before and it was repeatable. I found that switching on/off the main beams while idling was shifting the idle RPM by 300-400ish RPM (i.e., when I switched the lights the RPM dropped from 1200 to 800 and when I switched them again the went back from 800 to 1200). I could not capture the data from this (as I did not have my computer with me).

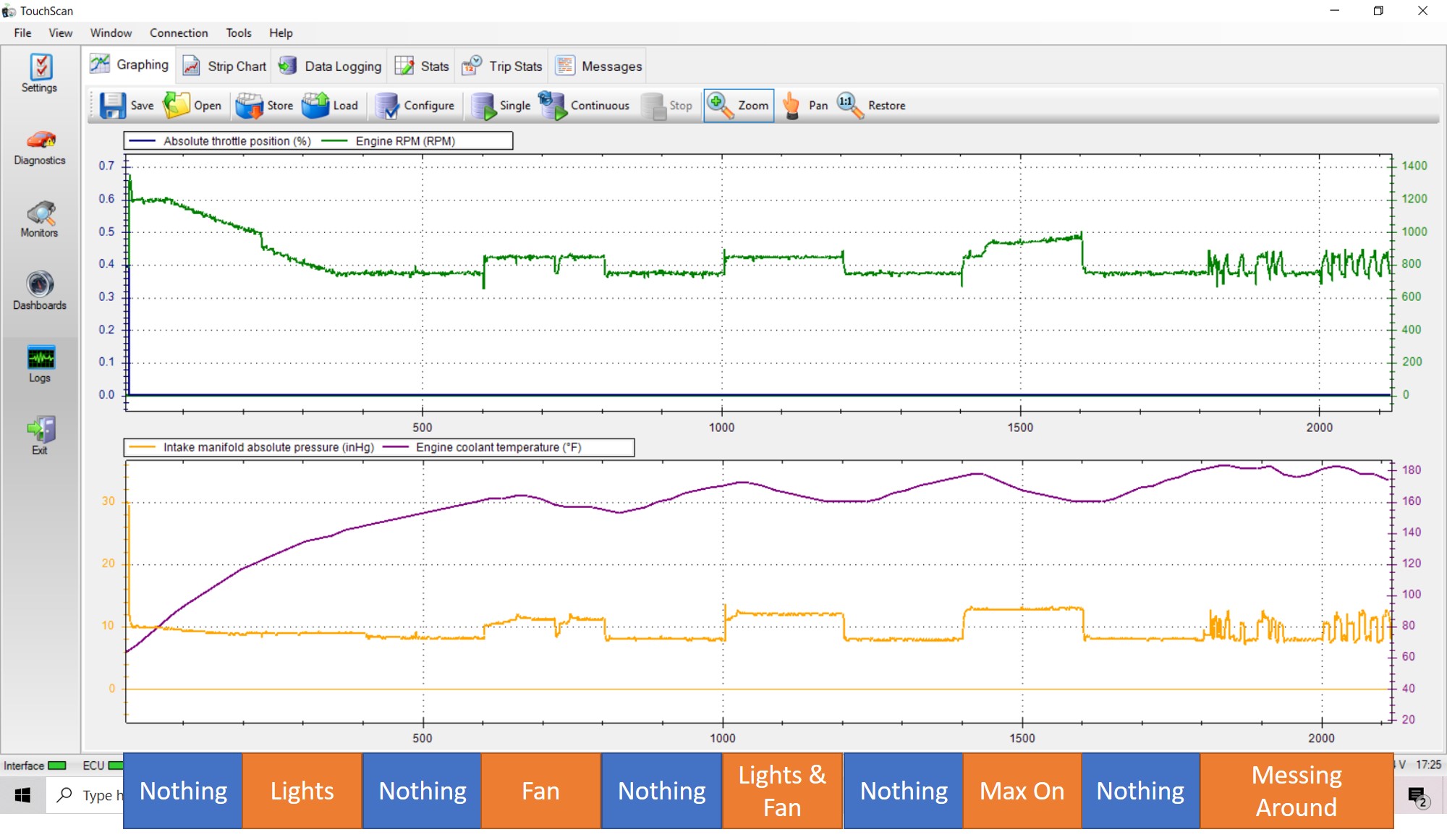

By the time I got home it was not as bad as this but I looked carefully at the RPM and Intake Manifold Pressure as I switched the electrical load in the car (e.g., turning on/off the main lights and the cabin blower).

The plots below are for a cold engine started and warming up. It was idling all the time and I basically tested: turning on main beam lights, turning on the cabin fan/blower, turned on both lights and fan, turned on everything I could (labelled "max on" with lights, fan, rear demister, radio, emergency indicators all on), and then messed around with turning things on and off. In between each of these I had a period of nothing on to re-establish a baseline before the next test. Note: for the "max on" test I felt like the engine was periodically misfiring - e.g., I could feel a periodic tremor in the car.

I undertook a more specific test where I switched on/off the cabin fan/blower every 20 seconds to check the impact it had and the data plots are shown below. The MAP reading is significantly affected (60% increase) and I assume that this is not expected. Interestingly the RPM was very solid on the dashboard but can be seen to move in the data stream. Also note in the plot that the throttle position sensor is slightly off (0.8%) for half the test. Again note that this is not as severe as when I first noticed but this does not look right to me.

Summary:

So where am I now. Well I suspect:

- Vacuum Leak - None or at least not a major one. Blocking the Throttle Body killed the engine pretty quickly. Might have a leak through the brake booster line but not one that is affecting idle when the brake is not in use. Good idle can be achieved and sustained some of the time so if it is a vacuum leak it is not consistent - possible intermittent leak but this feels less convincing

- Sensors - Seem fine. I have changed the major ones for high idle: the throttle body replacement had integrated idle control valve and throttle position sensor and I replaced the MAP sensor. Have not found any smoking gun in terms of bad data on the live data reader

- Electrical Harnessing and Supply Voltages - this feels like the key issue. I suspect I have an electrical issue somewhere (not sure about supply, maybe ground). The persisting error code (P1020) relates to a detected voltage mismatch issue. The tests with electrical load showed that turning on/off the lights could restore idle to correct level! This aligns with my feeling that I was struggling to find consistencies in the issues I face.

What do you think? Is an electrical issue the key target now? If so what should I check next?

Side Note:

I really appreciate all the help and support that you have all provided. I apologise that I struggle to find the time in life to get to testing this and providing feedback to your questions. You have all been so responsive but I can only typically find the time (and light) to look at this at the weekend. Thanks.