I'm restoring an 850 spider and the engine runs but really struggles to accelerate enough to drive in any gear. I have to rev it really high and as I release the clutch, the power drops fast and I can barely go. I thought the carb needed rebuilding so I had it rebuilt. However, even after that, it still acts the same. I'm guessing the carb isn't calibrated correctly but I don't know how to calibrate them. Any ideas what's causing the issues? I attached a couple of pics of the carb and can upload more if needed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Acceleration Issues

- Thread starter ace123

- Start date

Currently reading:

Technical Acceleration Issues

First I assume the engine generally is running sweet, starts easily and runs evenly with no misfires etc. no excessive engine smoke, overheating, loss of oils or coolants,ignition timing correct and advance and retard mechanism all working correctly.I'm restoring an 850 spider and the engine runs but really struggles to accelerate enough to drive in any gear. I have to rev it really high and as I release the clutch, the power drops fast and I can barely go. I thought the carb needed rebuilding so I had it rebuilt. However, even after that, it still acts the same. I'm guessing the carb isn't calibrated correctly but I don't know how to calibrate them. Any ideas what's causing the issues? I attached a couple of pics of the carb and can upload more if needed.

After that check that when the accelerator pedal is fully depressed the first and second butterfly flaps are fully opening on the carb. Following that I assume the fuel is good and a good supply to the carb.

After all that, then I would strip the carb and check no blockages/dirt in any jets etc.

As an apprentice in the late 60s I did work on the 850s in Fiat and Seat versions as they were a popular car then, though not the Spider.

Not a racing car but certainly quick enough to keep up with modern traffic I would say as not a heavy vehicle.

Hi @ace123,I'm restoring an 850 spider and the engine runs but really struggles to accelerate enough to drive in any gear. I have to rev it really high and as I release the clutch, the power drops fast and I can barely go. I thought the carb needed rebuilding so I had it rebuilt. However, even after that, it still acts the same. I'm guessing the carb isn't calibrated correctly but I don't know how to calibrate them. Any ideas what's causing the issues? I attached a couple of pics of the carb and can upload more if needed.

I had a similar issue when I put the engine back into my 900T.

It turned out that the throttle cable had too much slack.

With the ignition off, ask someone to press the accelerator pedal down as far as it will go while you check the throttle linkage.

If the throttle doesn't open up all the way you may need to adjust the the slack etc.

Assuming the carb is working okay following the rebuild, the other area to check is the fuel flow rate.

Have you got a blocked filter etc.

Take the fuel pipe off the carb (and disconnect the HT leads) and get someone to crank the engine over (if a mechanical pump, or run the electric pump), while collecting the fuel in a suitably large container. Is there a strong steady flow?

If not remove any in-line filters and use an airline (a foot pump is fine for this) and blow air back along the fuel lines to help clear any blockages - you should hear bubbling in the fuel tank.

Warning: When you release the pressure you may get a surge of petrol back down the fuel pipe (if you left the petrol cap on). Be ready to catch this.

BTW this is a good sign that your fuel line is clear of blockages.

Don't forget to blow through the return fuel line as well... a blockage here could cause back pressure stopping the fuel flow.

Finally,

Thanks for posting the photos of the carb.

I got hold of a twin choke carb sometime ago but the linkage was missing. I now have an idea of how to replace it - need to rebuild it first though as it's been sitting in a box for a few years.

Good luck.

- Joined

- Feb 28, 2016

- Messages

- 931

- Points

- 251

you have a square box type electric fuel pump.

These pumps dont like being mounted above the fuel, if the pump has to suck up it may not build proper flow/ pressure. Try removing it from its mounts and lowering it level with the bottom of the tank or lower.

Tim

These pumps dont like being mounted above the fuel, if the pump has to suck up it may not build proper flow/ pressure. Try removing it from its mounts and lowering it level with the bottom of the tank or lower.

Tim

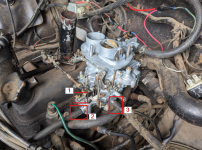

thanks for all the good feedback...I will try those suggestions. Another thing that is likely a problem is I noticed the carb has three outlets coming off the bottom of it that I don't know what they are for. I attached a pic highlighting them. Two have plugged hoses hooked up to them and one has nothing on it. I'm assuming they are important but have no clue what they are for.

Attachments

- Joined

- Feb 28, 2016

- Messages

- 931

- Points

- 251

Thats an American smog reg inlet manifold. Either block them temporarily or find a European one.

Also…check the coil…I did all the carb cleaning/gaskets/float/linkages etc (903 amigo) and the coil was breaking down under load…I missed it and I’m an ex Fiat trained auto electrician

Hi @ace123,

I took my 900T out for a run last weekend, to make sure nothing had seized etc. (had been laid up for over 2 years).

Apart from running a bit hot (I'm working on that) all seemed to be okay.

However, the fuel tank was only on 1/4 and the fuel nearly 3 years old so I thought I'd top the tank up with a couple of gallons (E5 Super).

That's when the problems started... kept cutting out every few yards (took over an hours to drive the few miles back home).

Adding fuel must have stirred up the rust in the tank, blocking the fuel filters and fuel lines.

I have a clear (glass) filter fitted just before the electric fuel pump. This didn't look too bad but it was only 1/3 full of fuel so I changed it... still only 1/3 full with a clean filter. Seemed odd, so I used a foot pump and blew air back along the fuel line to the tank (petrol cap removed) - you can hear the bubbles in the tank. After reconnecting the fuel line the glass filter is now full - there must have been some muck in the fuel line or main pick up in the tank.

Next to the carb - the small carb filter was full of rust.

Annoyingly, I dropped this into the engine bay, never to be seen again Luckily I have an old carb for spare parts and I have one in that... I doubt you can buy them anymore.

Luckily I have an old carb for spare parts and I have one in that... I doubt you can buy them anymore.

I'm going to fit an extra in-line filter just ahead of the carb to help catch the left over muck before it gets to the carb. However, before I fire her up again I need to check the float chamber for muck and clear the jets.

Ironically, this may also help with the hot running as it's likely to have been running very lean with all the muck in there.

If you haven't already, check the fuel flow to the carb. It's probably worth reverse blowing the fuel lines as a precaution - Make sure you remove the fuel tank cap first, otherwise the pressure build up will force the petrol back once you stop the airline.

Hope this helps.

I took my 900T out for a run last weekend, to make sure nothing had seized etc. (had been laid up for over 2 years).

Apart from running a bit hot (I'm working on that) all seemed to be okay.

However, the fuel tank was only on 1/4 and the fuel nearly 3 years old so I thought I'd top the tank up with a couple of gallons (E5 Super).

That's when the problems started... kept cutting out every few yards (took over an hours to drive the few miles back home).

Adding fuel must have stirred up the rust in the tank, blocking the fuel filters and fuel lines.

I have a clear (glass) filter fitted just before the electric fuel pump. This didn't look too bad but it was only 1/3 full of fuel so I changed it... still only 1/3 full with a clean filter. Seemed odd, so I used a foot pump and blew air back along the fuel line to the tank (petrol cap removed) - you can hear the bubbles in the tank. After reconnecting the fuel line the glass filter is now full - there must have been some muck in the fuel line or main pick up in the tank.

Next to the carb - the small carb filter was full of rust.

Annoyingly, I dropped this into the engine bay, never to be seen again

I'm going to fit an extra in-line filter just ahead of the carb to help catch the left over muck before it gets to the carb. However, before I fire her up again I need to check the float chamber for muck and clear the jets.

Ironically, this may also help with the hot running as it's likely to have been running very lean with all the muck in there.

If you haven't already, check the fuel flow to the carb. It's probably worth reverse blowing the fuel lines as a precaution - Make sure you remove the fuel tank cap first, otherwise the pressure build up will force the petrol back once you stop the airline.

Hope this helps.

Yes definitely remove fuel filler cap before blowing back to tank, as an apprentice I didn't on an old Mk3 Ford Zephyr of mine and resulted in the total demise of a rusty fuel tank.

While not helpful to the OP I really feel for you Gary, you've been fighting that overheating for a while now from memory.Hi @ace123,

I took my 900T out for a run last weekend, to make sure nothing had seized etc. (had been laid up for over 2 years).

Apart from running a bit hot (I'm working on that) all seemed to be okay.

However, the fuel tank was only on 1/4 and the fuel nearly 3 years old so I thought I'd top the tank up with a couple of gallons (E5 Super).

That's when the problems started... kept cutting out every few yards (took over an hours to drive the few miles back home).

Adding fuel must have stirred up the rust in the tank, blocking the fuel filters and fuel lines.

I have a clear (glass) filter fitted just before the electric fuel pump. This didn't look too bad but it was only 1/3 full of fuel so I changed it... still only 1/3 full with a clean filter. Seemed odd, so I used a foot pump and blew air back along the fuel line to the tank (petrol cap removed) - you can hear the bubbles in the tank. After reconnecting the fuel line the glass filter is now full - there must have been some muck in the fuel line or main pick up in the tank.

Next to the carb - the small carb filter was full of rust.

Annoyingly, I dropped this into the engine bay, never to be seen againLuckily I have an old carb for spare parts and I have one in that... I doubt you can buy them anymore.

I'm going to fit an extra in-line filter just ahead of the carb to help catch the left over muck before it gets to the carb. However, before I fire her up again I need to check the float chamber for muck and clear the jets.

Ironically, this may also help with the hot running as it's likely to have been running very lean with all the muck in there.

If you haven't already, check the fuel flow to the carb. It's probably worth reverse blowing the fuel lines as a precaution - Make sure you remove the fuel tank cap first, otherwise the pressure build up will force the petrol back once you stop the airline.

Hope this helps.

Ace, have you good spark, new leads, plugs, points, condenser, cap and coil? I'd be looking at ignition, sounds like its falling under load. I had a carb on my 650 fitted 500 and it turned out to be one of those electronic ignitions, went back to points and away she went. Car would idle fine but under load it fell down.

On going to breakdowns in the past where aftermarket electronic ignition had failed it was a tow back to the garage, whereas vehicles with points setup could usually be got running at the side of the road for a few pounds.

Hi @ace123,

I've located the instructions I found for the Weber 20 DIC (attached), just in case you don't have them.

I've also attached a photo of the carb fitted. Unfortunately, not my vehicle, I came across this photo ages ago when trying to figure out how to fit the carb.

In the photo you can see a drip tray fitted between the carb and inlet manifold. There is a similar drip tray fitted to the Weber 30 ICF, as fitted to my van currently.

As I understand it, the drip tray is to catch petrol drips and allows them to evaporate, rather than drip onto the engine. I'm assuming this is pretty important - other forum members may be able to confirm if it's safe to run without it. For the moment, I don't want to swap the carb without it... I expect finding a tray will be difficult, so will need to be fabricated (has anyone got one spare and/or able/willing to make a template from one?).

Cheers

Gary

PS. Rebuilt and refitted my carb (as mentioned earlier), it didn't seem to mucky. However, my engine now runs as rough as a bag of spanners and won't tick over without choke even when up to temperature. Adjusting the slow running mixture screw makes little difference, I'm guessing that I still have a blocked jet or pathway and will need to strip the carb down again

BTW The Haynes manual notes the rickover should be 850 RPM give or take 50 RPM.

I've located the instructions I found for the Weber 20 DIC (attached), just in case you don't have them.

I've also attached a photo of the carb fitted. Unfortunately, not my vehicle, I came across this photo ages ago when trying to figure out how to fit the carb.

In the photo you can see a drip tray fitted between the carb and inlet manifold. There is a similar drip tray fitted to the Weber 30 ICF, as fitted to my van currently.

As I understand it, the drip tray is to catch petrol drips and allows them to evaporate, rather than drip onto the engine. I'm assuming this is pretty important - other forum members may be able to confirm if it's safe to run without it. For the moment, I don't want to swap the carb without it... I expect finding a tray will be difficult, so will need to be fabricated (has anyone got one spare and/or able/willing to make a template from one?).

Cheers

Gary

PS. Rebuilt and refitted my carb (as mentioned earlier), it didn't seem to mucky. However, my engine now runs as rough as a bag of spanners and won't tick over without choke even when up to temperature. Adjusting the slow running mixture screw makes little difference, I'm guessing that I still have a blocked jet or pathway and will need to strip the carb down again

BTW The Haynes manual notes the rickover should be 850 RPM give or take 50 RPM.

Attachments

Yes, those ‘drip trays’ were fitted on lots of cars, not just fiats and not just on webers.

I’ve seen lots of cars that have deleted them and, let’s face it, all the manufacturers did.

There is the argument that they were there to stop petrol landing directly onto to the hottest surfaces and igniting BUT were more for being a cooling barrier between the hottest surfaces and the carb, so reducing hot starting/running issues.

Some say you have to fit an equivalent thickness spacer, if deleted, some not, what difference half a mil would make is beyond me…

I think, try it, if you get hot start/vapor issues, and still don’t want to source a plate, you could make a much taller spacer.

I’ve seen lots of cars that have deleted them and, let’s face it, all the manufacturers did.

There is the argument that they were there to stop petrol landing directly onto to the hottest surfaces and igniting BUT were more for being a cooling barrier between the hottest surfaces and the carb, so reducing hot starting/running issues.

Some say you have to fit an equivalent thickness spacer, if deleted, some not, what difference half a mil would make is beyond me…

I think, try it, if you get hot start/vapor issues, and still don’t want to source a plate, you could make a much taller spacer.

May be unrelated but years ago working on Lada cars(Fiat 124 under license) with similar twin choke carbs, cleaning the idle jets wasn't enough as beneath them was a brass emulsion tube which if you jammed a match stick in could be drawn out, then by tapping on a firm surface a load of muck could be removed which considerably improved the running.The top needs to be off the carb to access these, by the way I assume float height correct also.

Also as @Gary50 mentioned earlier if any slack in throttle cable, although throttle first choke may open it can not always be enough to activate the second choke seriously restricting performance.

Sorry if trying to teach granny to suck eggs.

Also as @Gary50 mentioned earlier if any slack in throttle cable, although throttle first choke may open it can not always be enough to activate the second choke seriously restricting performance.

Sorry if trying to teach granny to suck eggs.

On older cars some had quite a thick "insulation" block of tufnel/plastic?Yes, those ‘drip trays’ were fitted on lots of cars, not just fiats and not just on webers.

I’ve seen lots of cars that have deleted them and, let’s face it, all the manufacturers did.

There is the argument that they were there to stop petrol landing directly onto to the hottest surfaces and igniting BUT were more for being a cooling barrier between the hottest surfaces and the carb, so reducing hot starting/running issues.

Some say you have to fit an equivalent thickness spacer, if deleted, some not, what difference half a mil would make is beyond me…

I think, try it, if you get hot start/vapor issues, and still don’t want to source a plate, you could make a much taller spacer.

If the carb mounting studs seem very long that may indicate something like the insulater block is missing.

The drip trays also had a pipe connected to direct any fuel away safely.

Had a Niva 1700i and it had the plate under the injector body…almost as if Lada didn’t trust the quality of the Russian built GM SPIOn older cars some had quite a thick "insulation" block of tufnel/plastic?

If the carb mounting studs seem very long that may indicate something like the insulater block is missing.

The drip trays also had a pipe connected to direct any fuel away safely.

Having said that, their plastics and rubber were diabolical

When I left the Lada Dealership around 1982 the 1600 Niva still had carb and out of alignment transfer boxes.

I thought it was only the first 1600s and that the fault was rectified…you could see the pressings overlapping the original wrong mountings…it’s the last years of the 1600’s that are the most prized, not just because they were better built than the first ones, but also more reliable electrics and induction than the 1700s. It’s also easier to stick the Fiat twin cam and diesel’s in the later 1600’s. The gearboxes in all versions were made of cheese so, to protect the selector forks, the prescribed fix was to overfill them by the gear lever plate…it actually worked!

I sold the last of my Niva donor car bits, in lockdown, to a bloke that was going to build an off-road special with a sofim 2.5 diesel

I sold the last of my Niva donor car bits, in lockdown, to a bloke that was going to build an off-road special with a sofim 2.5 diesel

Probably right, whilst I left to go self employed in 1982, the Lada agency had been moved to another company earlier so we only had our residual customers.I thought it was only the first 1600s and that the fault was rectified…you could see the pressings overlapping the original wrong mountings…it’s the last years of the 1600’s that are the most prized, not just because they were better built than the first ones, but also more reliable electrics and induction than the 1700s. It’s also easier to stick the Fiat twin cam and diesel’s in the later 1600’s. The gearboxes in all versions were made of cheese so, to protect the selector forks, the prescribed fix was to overfill them by the gear lever plate…it actually worked!

I sold the last of my Niva donor car bits, in lockdown, to a bloke that was going to build an off-road special with a sofim 2.5 diesel

One point of contention I felt was that due to my old boss being very tight on part exchanges, regular customers used to buy from another dealer and return to us in the workshop to do the after sales / servicing etc. as they appreciated the quality of work.

We had also been Mazda agents and when I went self employed I had one lady who would do a round trip of about 160+ miles for me to service the Mazda RX3 (rotary) she had bought from us originally, as she trusted no one else to know her vehicle.

Follow up to my earlier comment about the photos helping to see how the linkages fit.

I missed the obvious... the manifold supplied when I bought the Weber 30 DIC off Ebay is the wrong one for the engine.

The one supplied is straight, which means the carb is turned 90 degrees counter clockwise - so none of the linkages will work.

The search is now on for the correct manifold... has anyone seen one for sale?

I missed the obvious... the manifold supplied when I bought the Weber 30 DIC off Ebay is the wrong one for the engine.

The one supplied is straight, which means the carb is turned 90 degrees counter clockwise - so none of the linkages will work.

The search is now on for the correct manifold... has anyone seen one for sale?