lydecker777

Member

hi all,

ive got a 2005 x244 fiat ducato, the 2.0 engine..on 84k

driving up the motorway from work a couple weeks ago, 70mph, suddenly a loud engine noise, pulled over and thought injector? knocking, engine shuddering, no leaks etc even the recovery driver said almost certain its injector..

so ive ordered a fresh whole set of refurbished injectors, had trouble with number 1 not coming out, so had it hydraulically pulled ..

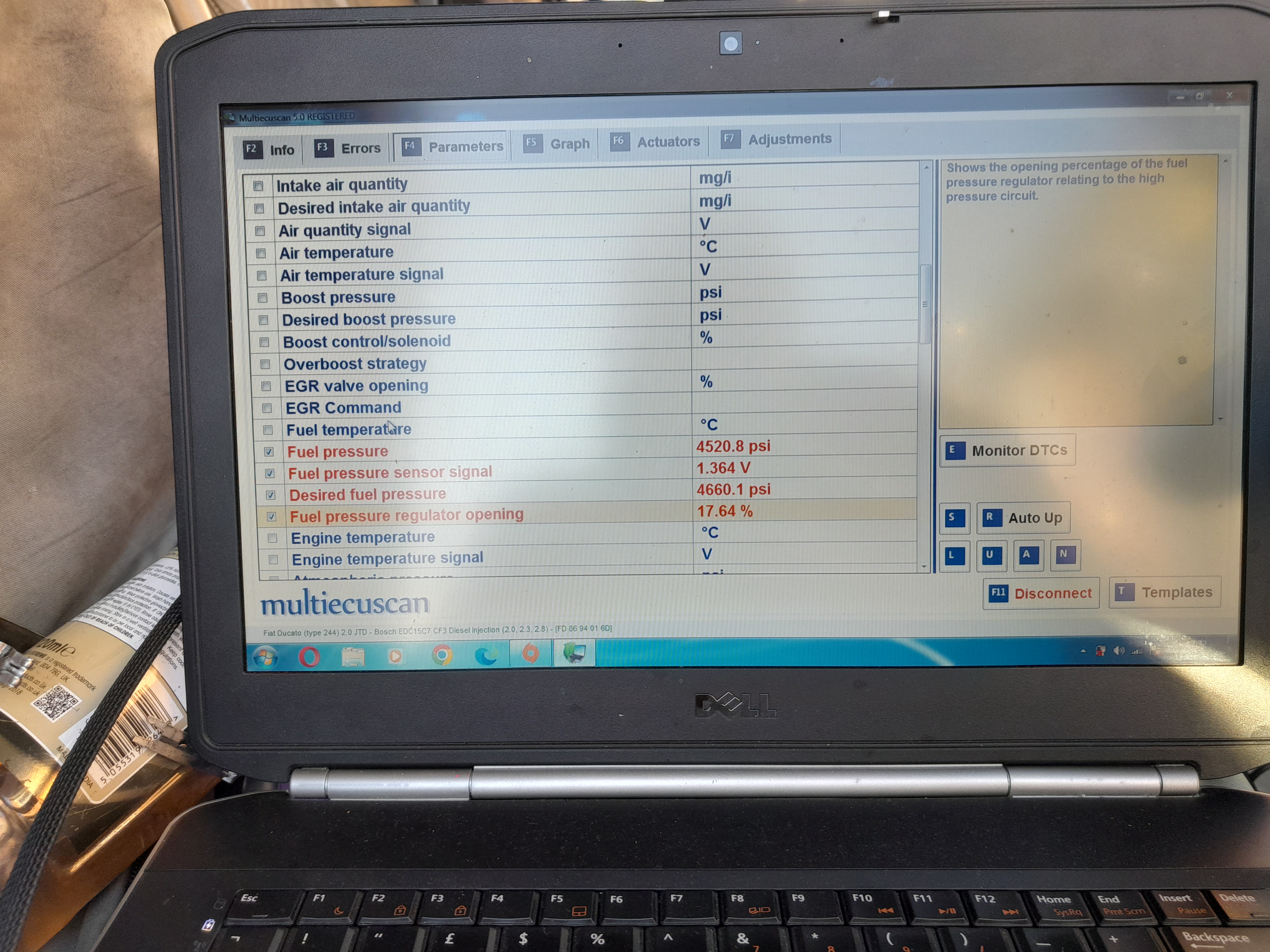

got multiscanecu put correct injector data in, injectors seated properly too

refitted , went to start, its takes a couple turns but starts and the engine doesnt shudder like before but the knocking still there ...

my thoughts are bottom end bearings now...

ive attached a video

if anyone thinks any different let me know

ive got a 2005 x244 fiat ducato, the 2.0 engine..on 84k

driving up the motorway from work a couple weeks ago, 70mph, suddenly a loud engine noise, pulled over and thought injector? knocking, engine shuddering, no leaks etc even the recovery driver said almost certain its injector..

so ive ordered a fresh whole set of refurbished injectors, had trouble with number 1 not coming out, so had it hydraulically pulled ..

got multiscanecu put correct injector data in, injectors seated properly too

refitted , went to start, its takes a couple turns but starts and the engine doesnt shudder like before but the knocking still there ...

my thoughts are bottom end bearings now...

ive attached a video

if anyone thinks any different let me know