Hi,

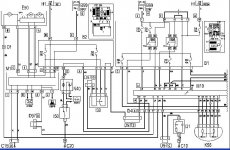

Been having problems with my Stilo 1,2 16V (2002) (again). Engine fault light is on and the fault code seems to be P0340 - Camshaft position sensor malfunction.

If I understand the eLearn manual correctly, it is located on the block near the spark plugs and the connector is on right hand side (looking the engine from the front).

Wires seem OK, the connector was not dirty and multimeter shows open circuit (infinite resistance) between all the pins leading to the sensor.

It seems that I need a new sensor (which costs a fortune) but is there anything special about installing new one? Take old one out and put new one back in? Is there anything more I could check, should there even be any "multimeter-measurable" resistance in the sensor when car is turned off. As I'm poor with cars, but some knowledge about electronics - Is there any faults to my reasoning?

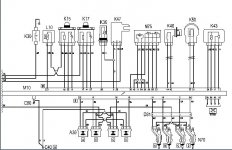

Been having problems with my Stilo 1,2 16V (2002) (again). Engine fault light is on and the fault code seems to be P0340 - Camshaft position sensor malfunction.

If I understand the eLearn manual correctly, it is located on the block near the spark plugs and the connector is on right hand side (looking the engine from the front).

Wires seem OK, the connector was not dirty and multimeter shows open circuit (infinite resistance) between all the pins leading to the sensor.

It seems that I need a new sensor (which costs a fortune) but is there anything special about installing new one? Take old one out and put new one back in? Is there anything more I could check, should there even be any "multimeter-measurable" resistance in the sensor when car is turned off. As I'm poor with cars, but some knowledge about electronics - Is there any faults to my reasoning?