My clutch has recently started slipping, only under load - on hills or acceleration. The revs rise and I have to back off to stop it slipping.

No history of a new clutch or hydraulics, 103k miles. Pedal action is fine, clutch engages and disengages fine.

I suspect oil contamination. Recently had a trip with some fairly steep hills and quite a heavy load on board, so it's been stressed a bit more than it's used to.

At one point after a climb there was an oil-burning sort of smell, but I wasn't 100% sure it was coming from the car. And for the first time, the engine lost a tiny amount of oil. Then the clutch slipped for the first time and has been doing it occasionally since.

There's nothing dripping on to the ground, but the bottom of the bell-housing is wet with oil. It doesn't smell, so I guess it must be engine oil.

So I'm guessing as well as a complete clutch kit, it will also need a rear crankshaft oil seal.

I was planning to do it myself as I've done a couple of clutches before, but never a rear main seal.

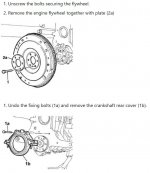

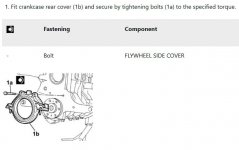

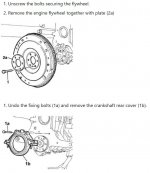

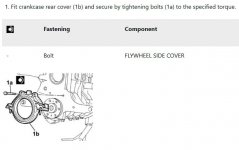

This is all I've found so far on 4cardata.info:

I'm hoping from this it should be a case of prising the seal out of the rear crankshaft cover and pressing a new one in.

Could anyone point me in the direction of a useful guide to changing the rear main seal, please? Would the Haynes manual be useful for this job? Would anyone be prepared to share any suggestions for the procedure, please?

I'll be sure to check the clutch fork and gearbox input shaft for play.

Is there anything else I should be looking at as a potential cause for oil contamination of the clutch? Anything else I should consider changing whilst the 'box and clutch are off?

As ever, thank you for any advice!

No history of a new clutch or hydraulics, 103k miles. Pedal action is fine, clutch engages and disengages fine.

I suspect oil contamination. Recently had a trip with some fairly steep hills and quite a heavy load on board, so it's been stressed a bit more than it's used to.

At one point after a climb there was an oil-burning sort of smell, but I wasn't 100% sure it was coming from the car. And for the first time, the engine lost a tiny amount of oil. Then the clutch slipped for the first time and has been doing it occasionally since.

There's nothing dripping on to the ground, but the bottom of the bell-housing is wet with oil. It doesn't smell, so I guess it must be engine oil.

So I'm guessing as well as a complete clutch kit, it will also need a rear crankshaft oil seal.

I was planning to do it myself as I've done a couple of clutches before, but never a rear main seal.

This is all I've found so far on 4cardata.info:

I'm hoping from this it should be a case of prising the seal out of the rear crankshaft cover and pressing a new one in.

Could anyone point me in the direction of a useful guide to changing the rear main seal, please? Would the Haynes manual be useful for this job? Would anyone be prepared to share any suggestions for the procedure, please?

I'll be sure to check the clutch fork and gearbox input shaft for play.

Is there anything else I should be looking at as a potential cause for oil contamination of the clutch? Anything else I should consider changing whilst the 'box and clutch are off?

As ever, thank you for any advice!

Last edited: