Hi,

Does anyone have some info on Electrical Diagrams. I see the 1.4 doesn't seem to be covered by the Haynes manuals. Not sure if the ELearn downloads cover it either (did try to install imgburn but my Antivirus threw a wobbly and said NO!)

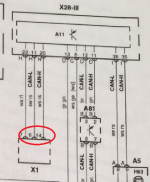

Ideally I could do with the 100HP Wiring Diagram for the Clutch Switch, Brake Switch and also Speed & Tacho signals so I can install my Cruise Control.

Any help greatly appreciated.

Cheers!

Does anyone have some info on Electrical Diagrams. I see the 1.4 doesn't seem to be covered by the Haynes manuals. Not sure if the ELearn downloads cover it either (did try to install imgburn but my Antivirus threw a wobbly and said NO!)

Ideally I could do with the 100HP Wiring Diagram for the Clutch Switch, Brake Switch and also Speed & Tacho signals so I can install my Cruise Control.

Any help greatly appreciated.

Cheers!