Introduction

Hey everyone.

Well a year or so ago my brother and i had the idea to get a van to convert into a camper. so we bought an Iveco Daily mk4 (2008). this was a refrigeration van. when we took apart the back of the van it had rather nice 50mm XPS insulation that we ended up recycling with much spare left over.

cut to a few months back, we still have the Daily which is still in the conversion stage but im enjoying it that much i want my own van. so i start looking at small vans. i originally was looking for a Doblo XL but i wanted something a little older, without advanced ECUs and emission controls. i went looking on Gumtree and saw this van for sale very cheap. i decided to go and have a look.

he told me it was being sold with faults. somehow over night it was draining its battery, and it over time started lacking in power. the chap had it in to a garage and they told him that it needs a complete new ECU to fix it. he was retiring from his self employed gardening business so the van was not needed as much as it used to be. fearing the cost of a replacement ECU and other faults that needed fixing he decided to sell it.

he also told me that he had the van a good 10 years or so and he religiously serviced it each year even if it did not clock up the required service mileage. on checking the dip stick i have never seen an engine so clean internally. not one bit of tarnish and the oil still a nice pleasant honey colour. little to no blow by and no noticeable oil leaks. Very Impressive.

on that i bought it.

i now was the registered keeper of a 2005 Dispatch "Enterprise 900" HDI with 99k miles on the clock for £325 with 12 months MOT.

my plans:

first off i wanted to install 2 extra seats to the van to make it a 5 seater. (more on that later!)

now i have someinteresting wild Insane plans for this van. i love electronics. i cant help myself. so heres a little list of what i plan:

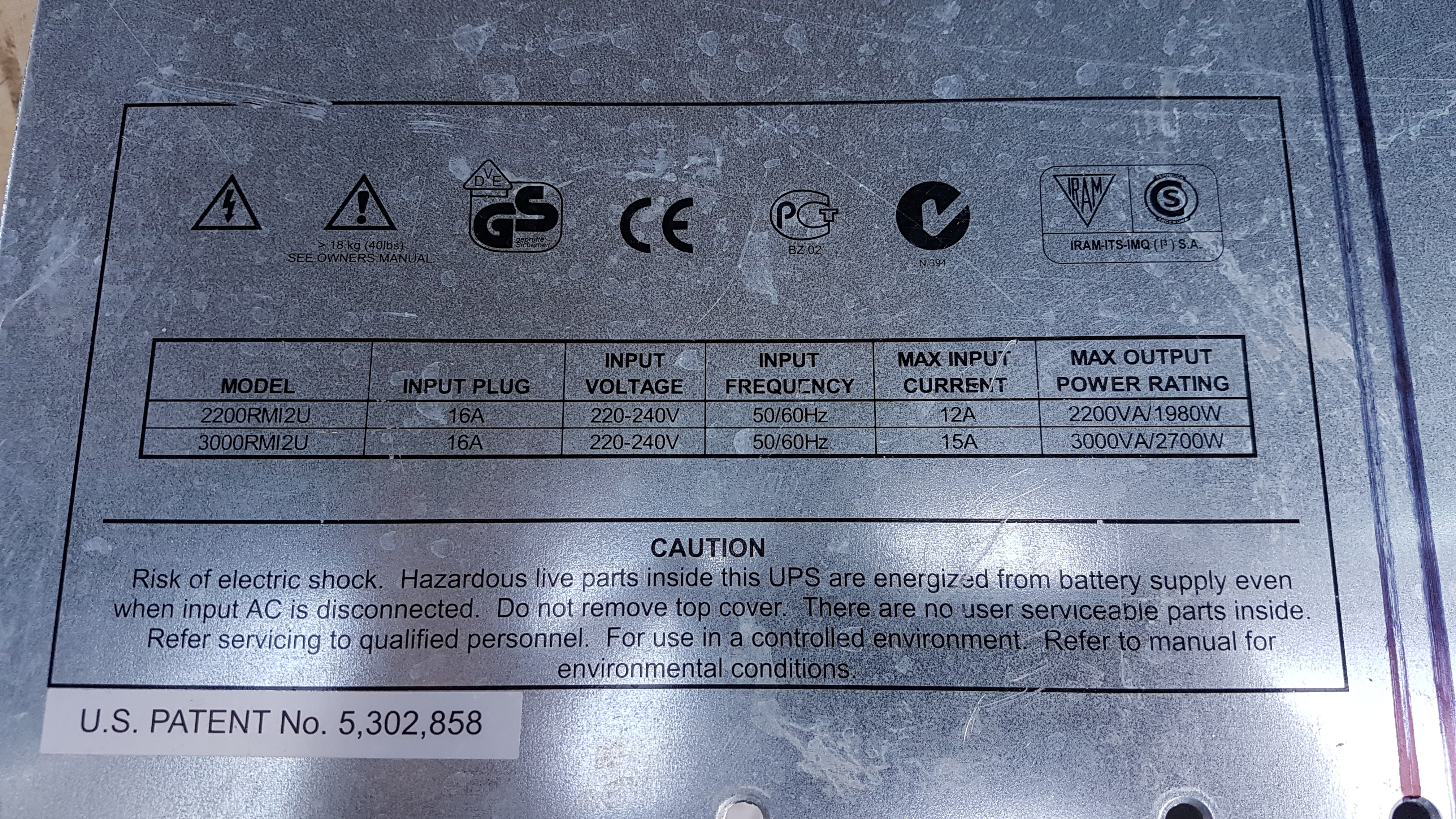

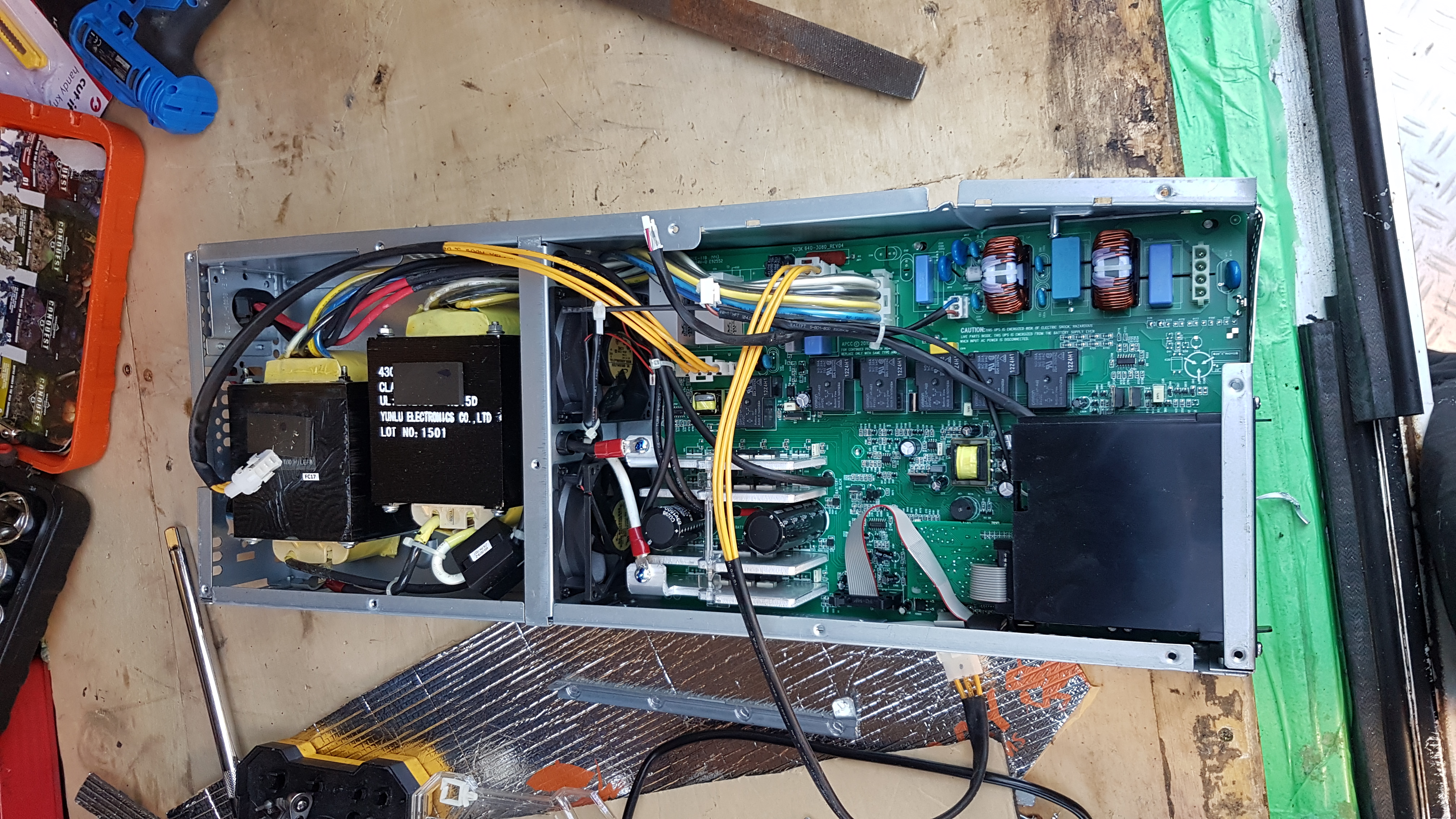

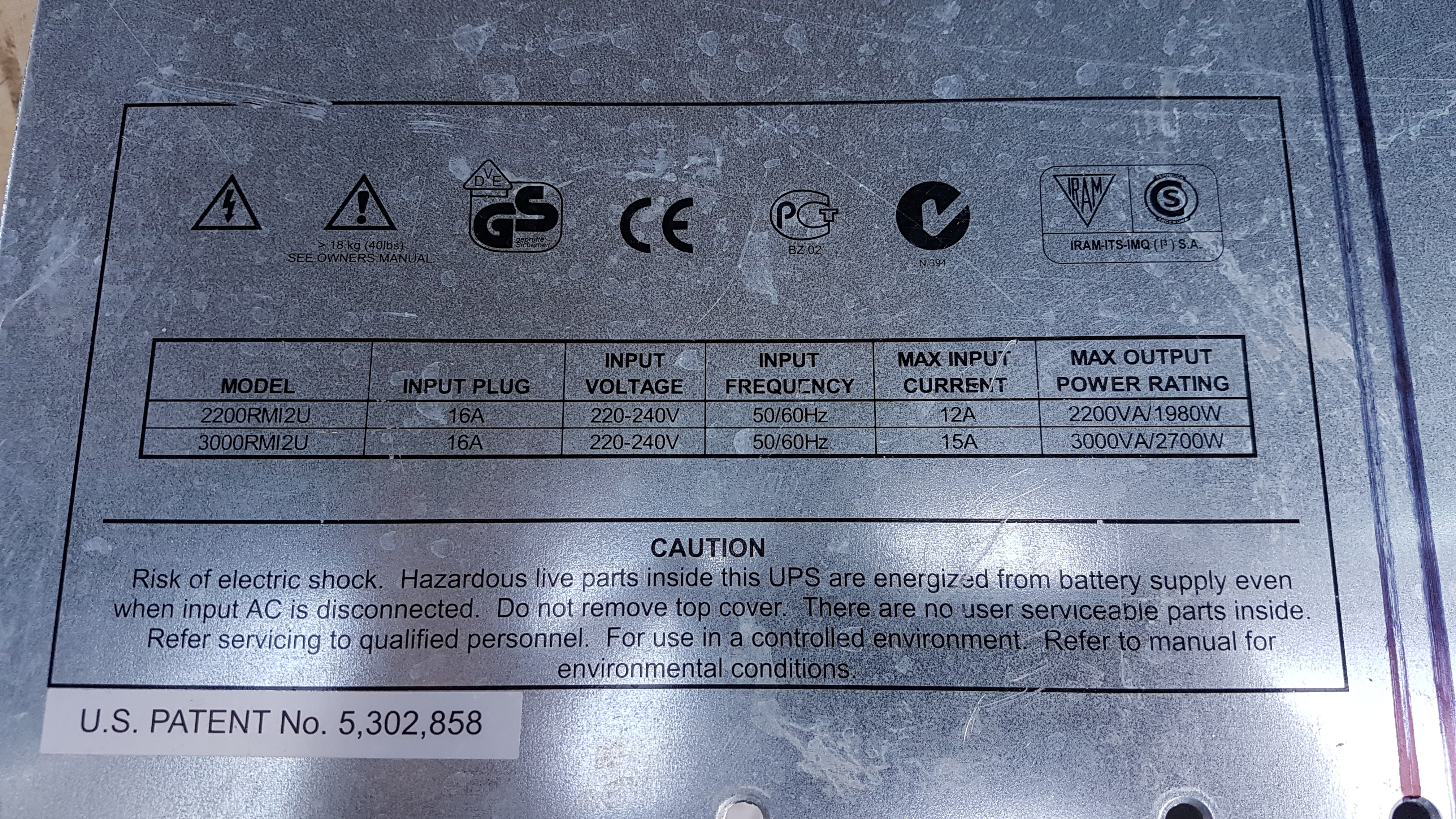

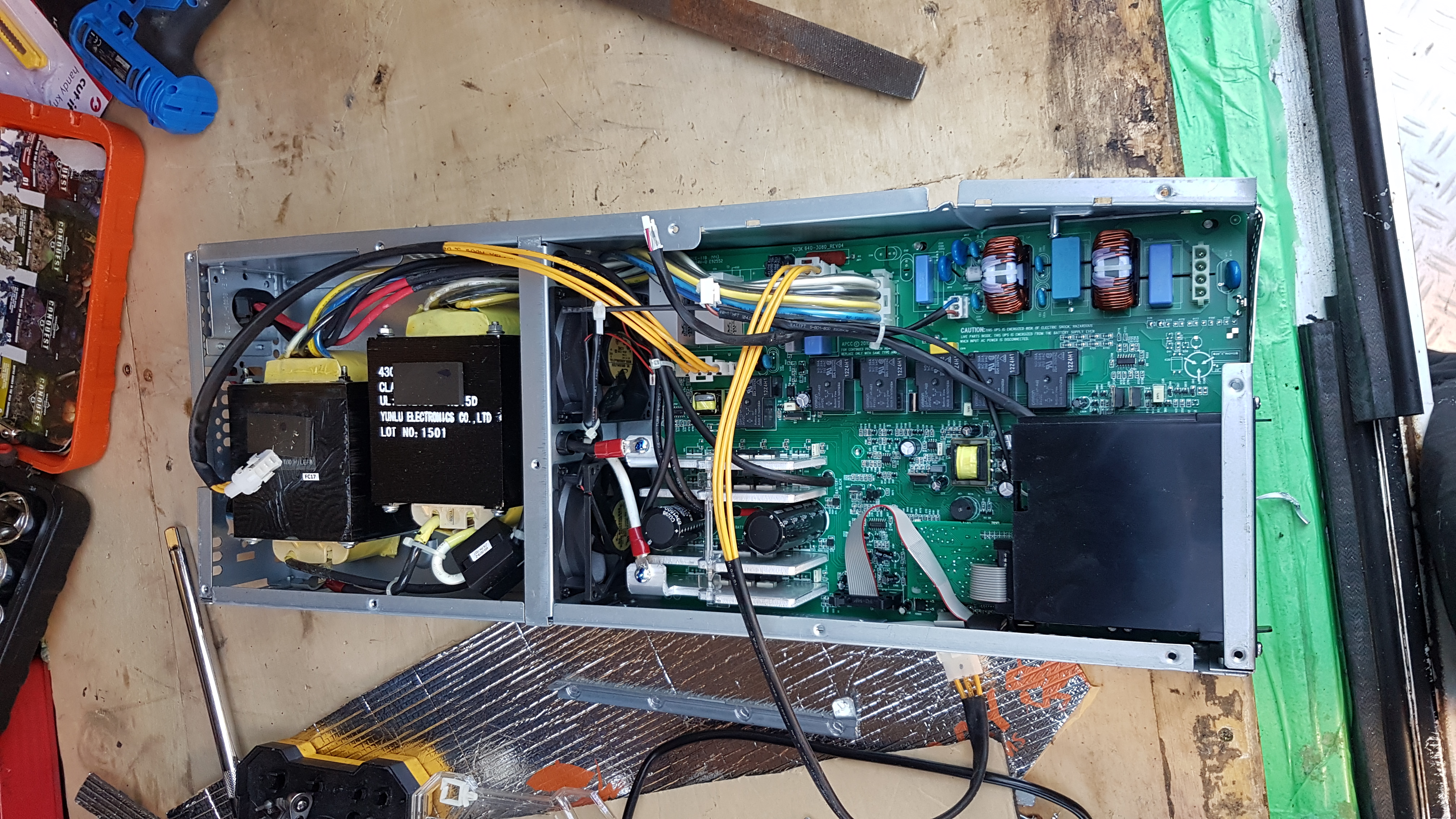

i plan to cram in a 48v leisure system to this van. the main component will be a heavily modified hacked and slashed 48v backup UPS (an APC SRT3000RMXLI)which will pretty much do everything for me. already having a mains charger built in, it also has a built in inverter at 2.7kw and being a UPS, if the electric hookup power fails, it will instantly switch over to battery power and keep all my 240v stuff working.

i will be using a "wind turbine" controller that i will use to tap directly into the alternators 3 phases to charge the 48v battery bank which i plan to store under the van in the gap the spare wheel usually hangs. ill be using gell cell / SLA, but if i can get my hands on some tasty AGM batteries i will use those.

the solar photovoltaic array i plan to have is also going to be pretty insane:

i plan to have a lot of solar power. i will be using a full sized roof rack on this van (that i may extend a little over the windscreen), and on that i plan to have a large roof box for storage (maybe 2) and maybe the spare wheel (though i may mount that to one of the rear doors). i plan on covering the roofbox(es) with semi-flexible solar panels. ive calculated that i should easy get 5x 18v 30 watt panels per roof box. each roof boxes solar panels will be linked in series so should get a nice 90 volts. if i do get another roof box i will add it in parallel to give my twice the amps output. i will then feed it into a Victron solar charger.

if that was not enough!

i will also have large pull out solar panels. these will be dual use. not only will they be able to be pulled out from under the roof rack for extra power, but they will also double up as a rain cover above the doors. i even have the plan on making them "push button deploy and retractable" using DC actuators. this however is something to do at my leisure as its more for "showing off"

im unsure of the total amount of watts all the panels combined will give but when the van is parked up at home it will be fed into our home self built solar array and power the house.

it does not end here however.

the van will also have a pressurised water system using a pump and bladder tank, both hot and cold running water. i will be using an old office drink water dispenser for the heating system. which has 2 modes, a 300w "instant heat" mode and a 30w "keep hot" mode where it stores water at a constant 60.c to 90.c (adjustable)

and lastly. yes there's more

i also plan to build my own refrigeration system in the van to run a fridge freezer. it will purely be a 48v system. the compressor and condenser (radiator on the back of a fridge) will be under the van (for noise and the coldest place giving the maximum efficiency) also saving internal space. ill be using a pre-built fridge i think. though not very well insulated (to my standards anyway) it will just make things easy.

i also plan on having a microwave grill too. that will be ran from the UPS inverter. should just about manage.

hacked and slashed

now that's out the way, here is what i have done so far:

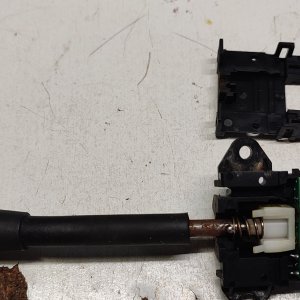

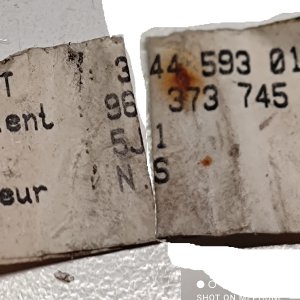

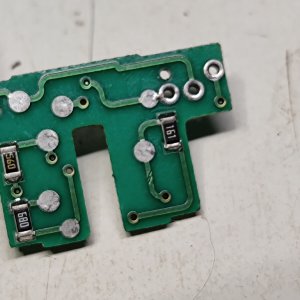

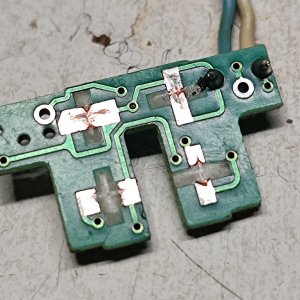

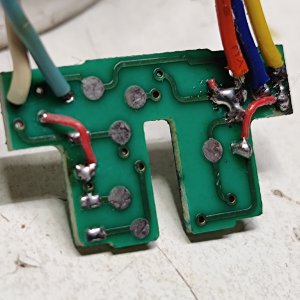

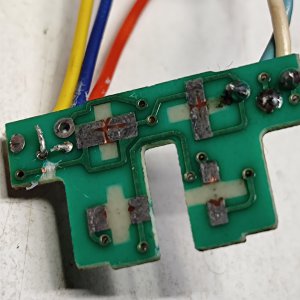

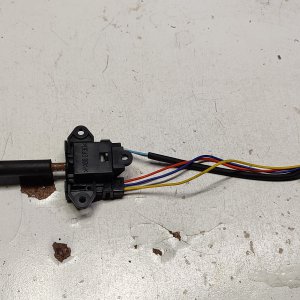

the evening i got it home i was sat in the van for a while reading through the booklets and various paperwork when i started hearing a buzzing/clicking sound. i traced the noise back to the rear left of the van, behind the lights. turns out the tow bar had an auto voltage detector for charging a caravans battery. this was looking pretty rough and quite melted to look at. i left it in place but pulled out the fuse. over the next 2 months i can report that the battery has never gone flat yet i have never really driven or even started the van up! will be an easy fix!

my first priority when i got the van home was to change the cam belt. 99k miles and a 15 year old cam belt is not odds that i like to play with. turns out its a really easy job on these vans. i locked the cam but never bothered locking the crank as i just used the visual timing mark to line it up. i replaced the water pump, tensioner and idler.i used a Gates timing belt kit. (we all know that they are the best!)

i also noticed that the throttle cable was very slack so "pegged" that back up a few notches. sadly this did not fix the engine power issue.

sadly this did not fix the engine power issue.

i also noticed that it had replacement discs and pads too!

now that was done i set about taking all of the original plywood out of the back. all in fantastic condition, all i planned to reuse again.

after cleaning the whole of the inside of the van with meths, my next priority was to install the extra 2 seats to the back. i wanted these seats totally removable as i still wanted to use it as a "lite van". my issue was that i wanted to have seats that could fold flat so i could lay a bed over the top of them. i also wanted them to have built in seat belts. all of which are quite rare things. i went into massive research looking for vehicles that have fold flat removable seats with built in seat belts. i eventually found out that Ford Transit Tourneo custom vans made after 2010 had just them! after contacting a few people i managed to buy two seats.

the seats fit perfectly in the original van floors "corrugation".

i welded in rather thick plate under the floor onto the chassis of the van so i had some very substantial seat mounting points. this did involve taking the fuel tank off in which i took advantage of the situation and repaired the very rusted fuel tank brace support, undersealed and rust proofed all chassis box sections using Dynax S50.

i bolted the seat runners in and installed the seats to test them before building the floor and its insulation.

i then set to insulating the back of the van. remember that 50mm XPS insulation i had left over? we that is what i used! this got used on the roof and the sides of the van. it fits perfectly depth wise.

i used expanding insulation foam (not the normal builders expanding foam) to hold the XPS in place. it also filled any missed cavities in the insulation due to my bad cutting skills.

for the floor i used 25mm square wooden batons and 25mm Celotex. then laid the original plywood flooring over the top of it all after cleaning and cutting out the holes for the now fitted rear seat mounting points.

i also insulated inside the steel cavities using polyester "teddy bear" stuffing as it does not hold moisture and remains breathable.

After all that was done i "sealed" everything in with thin plastic sheeting as a vapour barrier using aluminium tape to cover all of the holes into the cavities. (i also dynaxed some of the cavities, just for rust precaution)

i then covered all of the steelwork with 6mm closed cell foil lined foam. to give it a "warm/soft" touch then covered it all with Auto Carpet. no cold hard steelwork to touch in the middle of the night!

i did the same with the original plywood side panels after cleaning them and cutting them down to size to lay on top of the insulation vapour barrier.

i went for a dark grey auto carpet for all metal covering and a cream auto carpet to cover the plywood side panels. i will be using black auto carpet around the bottom of the "walls" of the living space. about 20cm from the floor up. i will disguise the colour change line using a thin strip of "ornate" aluminium checker plate.

i started work on a bulkhead with a plan to make a sizeable over head cupboard. before that i took out the old headlining, sound proofed and insulated the aerial with dense sound deadening sheeting and 10mm closed cell foam.

while i was under the van i had a poke around at the rust and made quite a "holy mess"... holy sh!t. well i can weld it all up but having done that much of it i am at the point where i just do not want to do that kind of thing anymore. i ordered new sills and planned to take it to a body shop to repair as they would make a much neat job of it than i would.

i planned to leave the roof with some plywood over it and then stain it a darker colour. however i am unsure with this idea and may change it.

from the photos you will notice that the van has a spinning roof vent. i have great plans for this. swapping out the vent for a low profile one so i can still fit my roof rack on. i plan to use it as an air intake system. now i suffer greatly with hay fever. so i will be building into the roof a HEPA air filtration system and aircraft style air vents. i am the kind of person that likes to sleep with the noise and feel of a fan blowing on me (i am really very highly strange). this in the summer months will be quite nice.

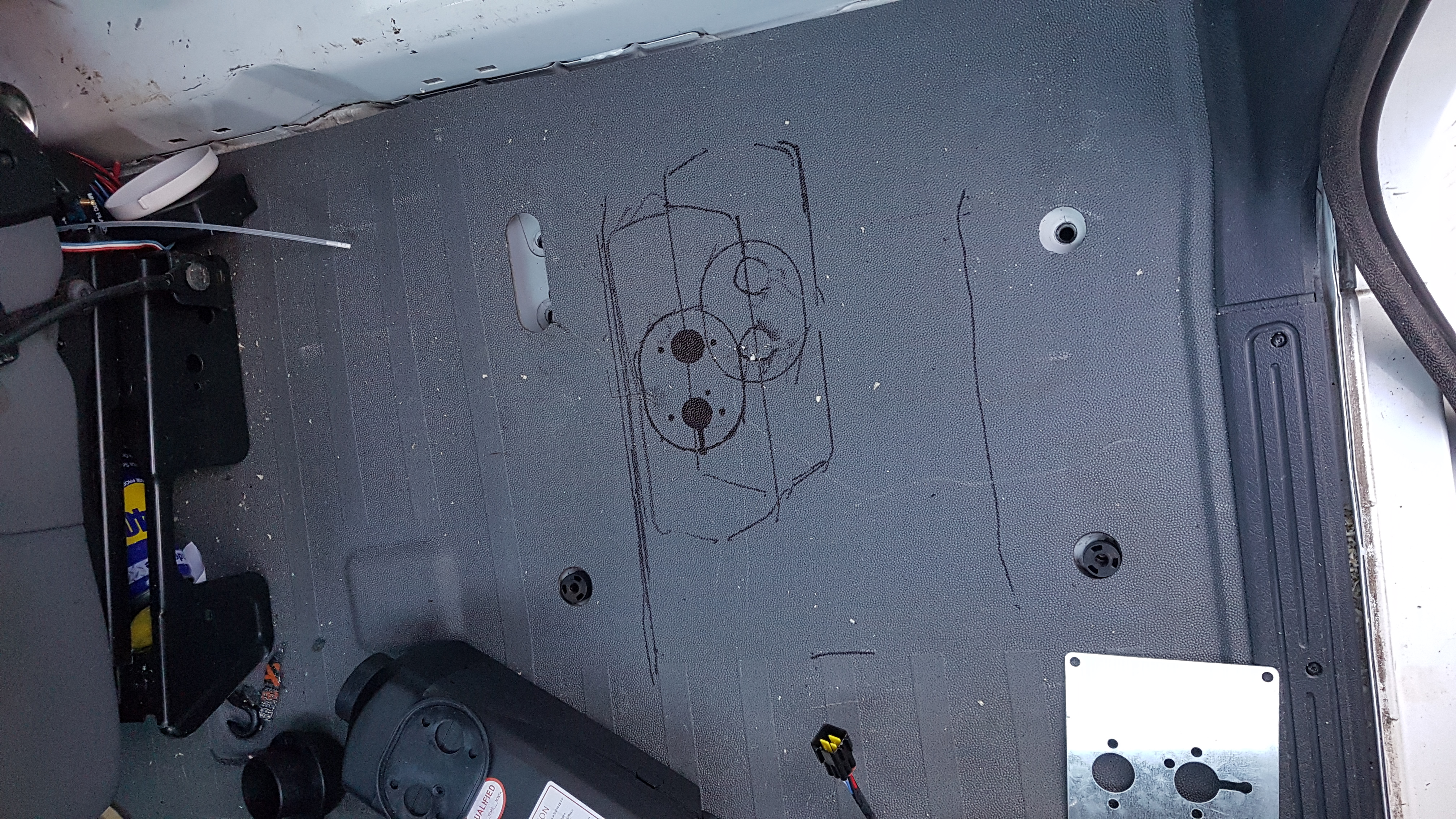

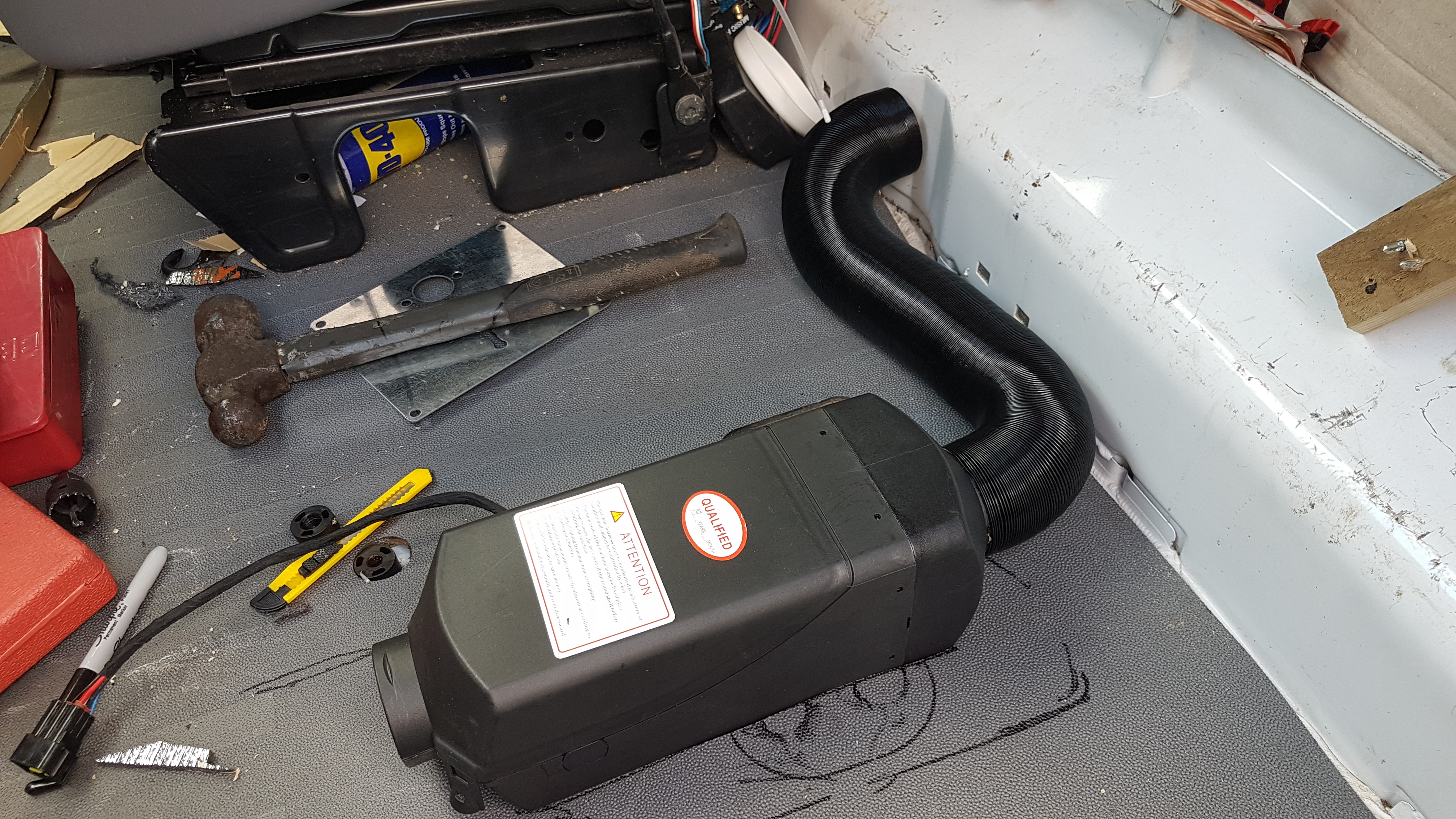

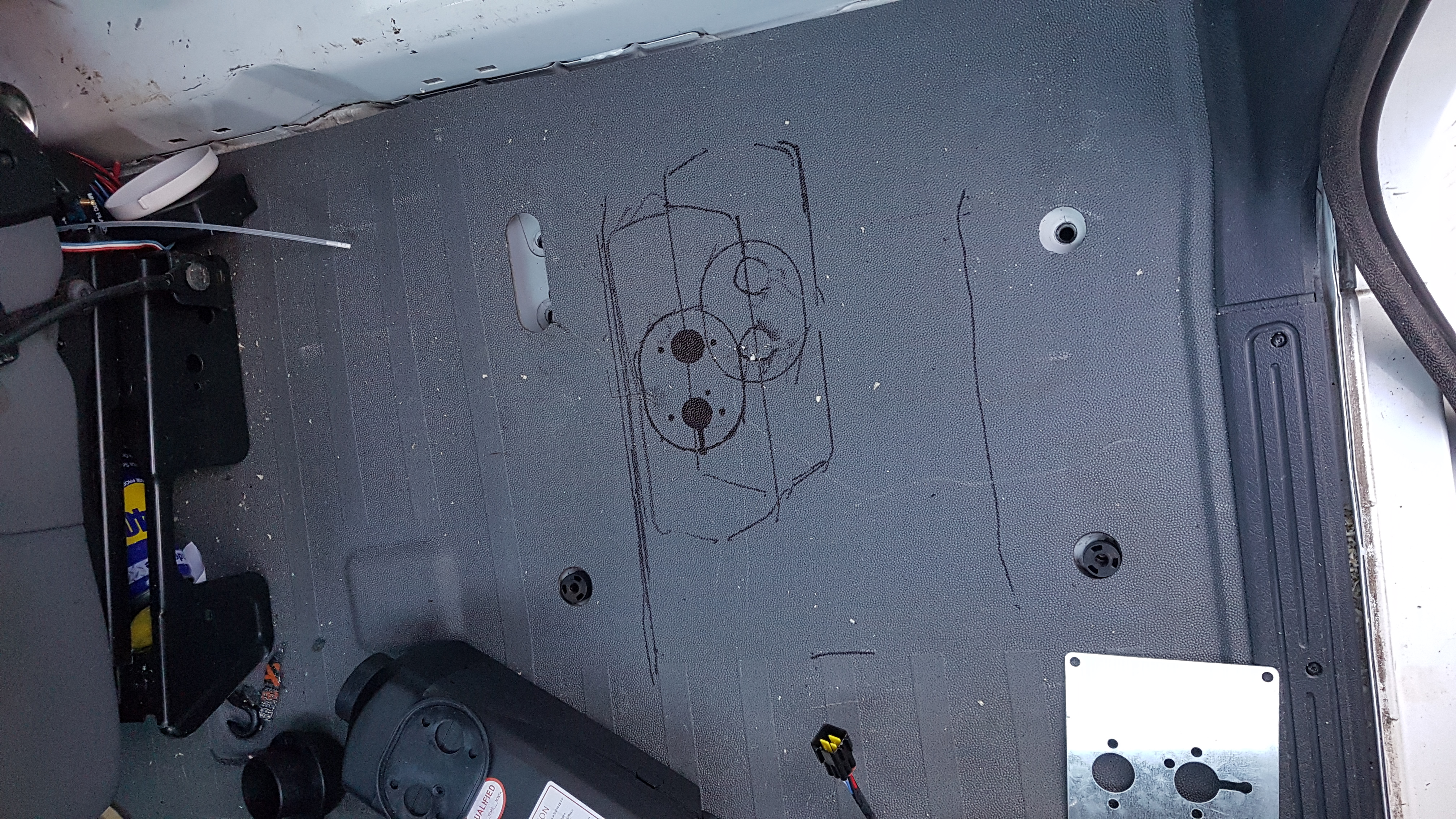

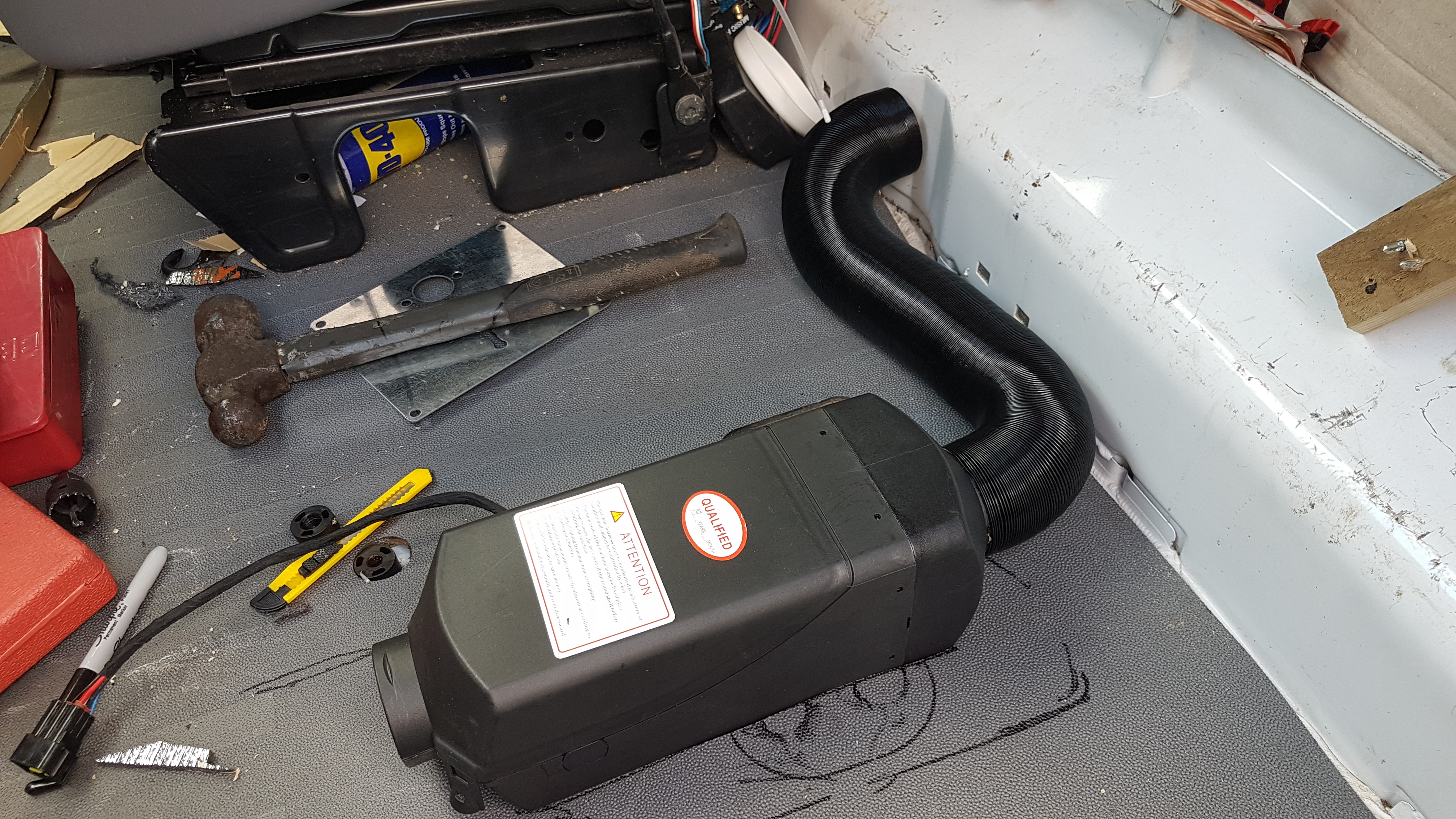

i have recently fitted a 2kw diesel air heater under the passenger seat. having cut out the "storage basket" to make way for it. i had to hammer flat some of the vans floor corrugation so it fit in nice and level. i did this using a trolley jack and a brick so i could hammer flat without concaving it. it fits in the gap really well but is close to fuel and brake lines under the van. i plan to make a heat shield for them. can never be too cautious. the heat output should blow nicely down the central walkway. between the seats and the kitchen units.

ok so as of today i have had the van for about 2 months and finally insured and taxed it. its insured as a camper in the conversion stage but still has SDPC specs so i can drive it to work

so far i have not looked into fixing the engine power issue. i took it out for my first drive in it and i was a little worried about it being as slow as it was. thankfully i know a thing or two about modernish diesel engines so i started to unplug sensors. well first sensor to unplug was the Mass Air Flow sensor (just behind the air filter box). low and behold it was like i hit LAUNCH on Saturn 5 rocket. that was easy. too easy. well i have ordered a replacement MAF sensor and a replacement inter cooler. i will fit them when they get here.

That is as far as i have got! on Friday i will be taking it into the body shop for the welding work to be done. the body shop specialises in repairing E7 Eurotaxis so no stranger to these vans. they also have many scrap taxis around the back. i may even buy all the bits to retrofit air conditioning to my van from them! just for the filtered air mainly!

thanks for looking! i will be sure to add more updates as it progresses.

just to note, i am keeping Vlogs on this hosted on Youtube.

see the playlist here:

https://www.youtube.com/playlist?list=PLq_C4DcbSFgILFitaYNBnZSO2ISNI3vhn

-JohnDragonMan

Well a year or so ago my brother and i had the idea to get a van to convert into a camper. so we bought an Iveco Daily mk4 (2008). this was a refrigeration van. when we took apart the back of the van it had rather nice 50mm XPS insulation that we ended up recycling with much spare left over.

cut to a few months back, we still have the Daily which is still in the conversion stage but im enjoying it that much i want my own van. so i start looking at small vans. i originally was looking for a Doblo XL but i wanted something a little older, without advanced ECUs and emission controls. i went looking on Gumtree and saw this van for sale very cheap. i decided to go and have a look.

he told me it was being sold with faults. somehow over night it was draining its battery, and it over time started lacking in power. the chap had it in to a garage and they told him that it needs a complete new ECU to fix it. he was retiring from his self employed gardening business so the van was not needed as much as it used to be. fearing the cost of a replacement ECU and other faults that needed fixing he decided to sell it.

he also told me that he had the van a good 10 years or so and he religiously serviced it each year even if it did not clock up the required service mileage. on checking the dip stick i have never seen an engine so clean internally. not one bit of tarnish and the oil still a nice pleasant honey colour. little to no blow by and no noticeable oil leaks. Very Impressive.

on that i bought it.

i now was the registered keeper of a 2005 Dispatch "Enterprise 900" HDI with 99k miles on the clock for £325 with 12 months MOT.

my plans:

first off i wanted to install 2 extra seats to the van to make it a 5 seater. (more on that later!)

now i have some

i plan to cram in a 48v leisure system to this van. the main component will be a heavily modified hacked and slashed 48v backup UPS (an APC SRT3000RMXLI)which will pretty much do everything for me. already having a mains charger built in, it also has a built in inverter at 2.7kw and being a UPS, if the electric hookup power fails, it will instantly switch over to battery power and keep all my 240v stuff working.

i will be using a "wind turbine" controller that i will use to tap directly into the alternators 3 phases to charge the 48v battery bank which i plan to store under the van in the gap the spare wheel usually hangs. ill be using gell cell / SLA, but if i can get my hands on some tasty AGM batteries i will use those.

the solar photovoltaic array i plan to have is also going to be pretty insane:

i plan to have a lot of solar power. i will be using a full sized roof rack on this van (that i may extend a little over the windscreen), and on that i plan to have a large roof box for storage (maybe 2) and maybe the spare wheel (though i may mount that to one of the rear doors). i plan on covering the roofbox(es) with semi-flexible solar panels. ive calculated that i should easy get 5x 18v 30 watt panels per roof box. each roof boxes solar panels will be linked in series so should get a nice 90 volts. if i do get another roof box i will add it in parallel to give my twice the amps output. i will then feed it into a Victron solar charger.

if that was not enough!

i will also have large pull out solar panels. these will be dual use. not only will they be able to be pulled out from under the roof rack for extra power, but they will also double up as a rain cover above the doors. i even have the plan on making them "push button deploy and retractable" using DC actuators. this however is something to do at my leisure as its more for "showing off"

im unsure of the total amount of watts all the panels combined will give but when the van is parked up at home it will be fed into our home self built solar array and power the house.

it does not end here however.

the van will also have a pressurised water system using a pump and bladder tank, both hot and cold running water. i will be using an old office drink water dispenser for the heating system. which has 2 modes, a 300w "instant heat" mode and a 30w "keep hot" mode where it stores water at a constant 60.c to 90.c (adjustable)

and lastly. yes there's more

i also plan to build my own refrigeration system in the van to run a fridge freezer. it will purely be a 48v system. the compressor and condenser (radiator on the back of a fridge) will be under the van (for noise and the coldest place giving the maximum efficiency) also saving internal space. ill be using a pre-built fridge i think. though not very well insulated (to my standards anyway) it will just make things easy.

i also plan on having a microwave grill too. that will be ran from the UPS inverter. should just about manage.

hacked and slashed

now that's out the way, here is what i have done so far:

the evening i got it home i was sat in the van for a while reading through the booklets and various paperwork when i started hearing a buzzing/clicking sound. i traced the noise back to the rear left of the van, behind the lights. turns out the tow bar had an auto voltage detector for charging a caravans battery. this was looking pretty rough and quite melted to look at. i left it in place but pulled out the fuse. over the next 2 months i can report that the battery has never gone flat yet i have never really driven or even started the van up! will be an easy fix!

my first priority when i got the van home was to change the cam belt. 99k miles and a 15 year old cam belt is not odds that i like to play with. turns out its a really easy job on these vans. i locked the cam but never bothered locking the crank as i just used the visual timing mark to line it up. i replaced the water pump, tensioner and idler.i used a Gates timing belt kit. (we all know that they are the best!)

i also noticed that the throttle cable was very slack so "pegged" that back up a few notches.

i also noticed that it had replacement discs and pads too!

now that was done i set about taking all of the original plywood out of the back. all in fantastic condition, all i planned to reuse again.

after cleaning the whole of the inside of the van with meths, my next priority was to install the extra 2 seats to the back. i wanted these seats totally removable as i still wanted to use it as a "lite van". my issue was that i wanted to have seats that could fold flat so i could lay a bed over the top of them. i also wanted them to have built in seat belts. all of which are quite rare things. i went into massive research looking for vehicles that have fold flat removable seats with built in seat belts. i eventually found out that Ford Transit Tourneo custom vans made after 2010 had just them! after contacting a few people i managed to buy two seats.

the seats fit perfectly in the original van floors "corrugation".

i welded in rather thick plate under the floor onto the chassis of the van so i had some very substantial seat mounting points. this did involve taking the fuel tank off in which i took advantage of the situation and repaired the very rusted fuel tank brace support, undersealed and rust proofed all chassis box sections using Dynax S50.

i bolted the seat runners in and installed the seats to test them before building the floor and its insulation.

i then set to insulating the back of the van. remember that 50mm XPS insulation i had left over? we that is what i used! this got used on the roof and the sides of the van. it fits perfectly depth wise.

i used expanding insulation foam (not the normal builders expanding foam) to hold the XPS in place. it also filled any missed cavities in the insulation due to my bad cutting skills.

for the floor i used 25mm square wooden batons and 25mm Celotex. then laid the original plywood flooring over the top of it all after cleaning and cutting out the holes for the now fitted rear seat mounting points.

i also insulated inside the steel cavities using polyester "teddy bear" stuffing as it does not hold moisture and remains breathable.

After all that was done i "sealed" everything in with thin plastic sheeting as a vapour barrier using aluminium tape to cover all of the holes into the cavities. (i also dynaxed some of the cavities, just for rust precaution)

i then covered all of the steelwork with 6mm closed cell foil lined foam. to give it a "warm/soft" touch then covered it all with Auto Carpet. no cold hard steelwork to touch in the middle of the night!

i did the same with the original plywood side panels after cleaning them and cutting them down to size to lay on top of the insulation vapour barrier.

i went for a dark grey auto carpet for all metal covering and a cream auto carpet to cover the plywood side panels. i will be using black auto carpet around the bottom of the "walls" of the living space. about 20cm from the floor up. i will disguise the colour change line using a thin strip of "ornate" aluminium checker plate.

i started work on a bulkhead with a plan to make a sizeable over head cupboard. before that i took out the old headlining, sound proofed and insulated the aerial with dense sound deadening sheeting and 10mm closed cell foam.

while i was under the van i had a poke around at the rust and made quite a "holy mess"... holy sh!t. well i can weld it all up but having done that much of it i am at the point where i just do not want to do that kind of thing anymore. i ordered new sills and planned to take it to a body shop to repair as they would make a much neat job of it than i would.

i planned to leave the roof with some plywood over it and then stain it a darker colour. however i am unsure with this idea and may change it.

from the photos you will notice that the van has a spinning roof vent. i have great plans for this. swapping out the vent for a low profile one so i can still fit my roof rack on. i plan to use it as an air intake system. now i suffer greatly with hay fever. so i will be building into the roof a HEPA air filtration system and aircraft style air vents. i am the kind of person that likes to sleep with the noise and feel of a fan blowing on me (i am really very highly strange). this in the summer months will be quite nice.

i have recently fitted a 2kw diesel air heater under the passenger seat. having cut out the "storage basket" to make way for it. i had to hammer flat some of the vans floor corrugation so it fit in nice and level. i did this using a trolley jack and a brick so i could hammer flat without concaving it. it fits in the gap really well but is close to fuel and brake lines under the van. i plan to make a heat shield for them. can never be too cautious. the heat output should blow nicely down the central walkway. between the seats and the kitchen units.

ok so as of today i have had the van for about 2 months and finally insured and taxed it. its insured as a camper in the conversion stage but still has SDPC specs so i can drive it to work

so far i have not looked into fixing the engine power issue. i took it out for my first drive in it and i was a little worried about it being as slow as it was. thankfully i know a thing or two about modernish diesel engines so i started to unplug sensors. well first sensor to unplug was the Mass Air Flow sensor (just behind the air filter box). low and behold it was like i hit LAUNCH on Saturn 5 rocket. that was easy. too easy. well i have ordered a replacement MAF sensor and a replacement inter cooler. i will fit them when they get here.

That is as far as i have got! on Friday i will be taking it into the body shop for the welding work to be done. the body shop specialises in repairing E7 Eurotaxis so no stranger to these vans. they also have many scrap taxis around the back. i may even buy all the bits to retrofit air conditioning to my van from them! just for the filtered air mainly!

thanks for looking! i will be sure to add more updates as it progresses.

just to note, i am keeping Vlogs on this hosted on Youtube.

see the playlist here:

https://www.youtube.com/playlist?list=PLq_C4DcbSFgILFitaYNBnZSO2ISNI3vhn

-JohnDragonMan