Working on your car brakes need's a lot of care if you are not 100% confident you can get the job right seek the help of a mechanic....

kit needed in addition to chocks and jack and stands.....

brake cleaner,

coper grease

hammer

BIG flat screw driver/ pry bar

pliers

wheel brace/ torque wrench (steel rims 105nm)

smaller slotted screwdriver

T30 torx driver (i used impact driver as mine were seized)

some rag

M10 x 3" or so bolts and spanner to suit...

First Chock the other wheels leave the car in gear but release handbrake fully and slacken wheel nuts...

raise the car safely and axle stand the side you are working on and remove wheel

now you are faced with the Drum/hub...

get your 30T Torx driver and remove the 2x torx screws.....

now with them both removed you need to pry the drum off evenly (a tap with a hammer round the edge can help)

AT this point you can go one of 2 ways..... my prefered method is to use 2 bolts in the threaded holes of the drum and wind the drum off occasionally tapping the drum to free the shoes off so the drum slips past them...

work the bolts alternately to keep the drum square to the hub stub watch for the wheel bearing rotating as you do this.. if you have this problem slide a screw driver into one of the wheel bolt holes to stop it rotating...

Or pry off using large flat screwdriver/ claw hammer slowly and evenly all the way round......

now you have the drum off (the hard part)

make a mental note of the internals

now remove the lower spring with pliers/ small flat screw driver

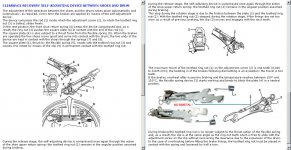

make a note of how the self adjuster is sat in the shoes

Then remove upper spring....

screw the end of the auto self adjuster clockwise several turns

(more on this later)

the pic below shows the left fork 180 degrees out of the seated position...

now remove 2x pad retainer clips

take care not to loose the pins from the back of the drum

pull shoes off pin

note Handbrake connections/linkages...

Now clean all surfaces with brake cleaner and rag....

now use copper grease on contact points...

Refit shoes ensuring they sit in the lower retainer and uppers sit against the Slave cylinder shafts...

next re fit the auto adjuster and the lower spring.......

at this point push the uppers together so the shoes push the self adjuster tight and try to fit drum back on

if its a tight fit remove adjuster and wind in. if very slack wind adjuster out so shoes just catch drum when re fitting....

now re fit upper spring...

then drum and torx screws

now to re adjust the shoes

climb into car carefully so as not to upset it on the jack

pump brakes slowly and listen for the clicks of the auto adjuster might take 50 or so pumps once it stops clicking it should be fully adjusted.....

then check handbrake operation and foot brake with a friend spinning hub

re fit wheel and torque up wheel nuts

kit needed in addition to chocks and jack and stands.....

brake cleaner,

coper grease

hammer

BIG flat screw driver/ pry bar

pliers

wheel brace/ torque wrench (steel rims 105nm)

smaller slotted screwdriver

T30 torx driver (i used impact driver as mine were seized)

some rag

M10 x 3" or so bolts and spanner to suit...

First Chock the other wheels leave the car in gear but release handbrake fully and slacken wheel nuts...

raise the car safely and axle stand the side you are working on and remove wheel

now you are faced with the Drum/hub...

get your 30T Torx driver and remove the 2x torx screws.....

now with them both removed you need to pry the drum off evenly (a tap with a hammer round the edge can help)

AT this point you can go one of 2 ways..... my prefered method is to use 2 bolts in the threaded holes of the drum and wind the drum off occasionally tapping the drum to free the shoes off so the drum slips past them...

work the bolts alternately to keep the drum square to the hub stub watch for the wheel bearing rotating as you do this.. if you have this problem slide a screw driver into one of the wheel bolt holes to stop it rotating...

Or pry off using large flat screwdriver/ claw hammer slowly and evenly all the way round......

now you have the drum off (the hard part)

make a mental note of the internals

now remove the lower spring with pliers/ small flat screw driver

make a note of how the self adjuster is sat in the shoes

Then remove upper spring....

screw the end of the auto self adjuster clockwise several turns

the pic below shows the left fork 180 degrees out of the seated position...

now remove 2x pad retainer clips

take care not to loose the pins from the back of the drum

pull shoes off pin

note Handbrake connections/linkages...

Now clean all surfaces with brake cleaner and rag....

now use copper grease on contact points...

Refit shoes ensuring they sit in the lower retainer and uppers sit against the Slave cylinder shafts...

next re fit the auto adjuster and the lower spring.......

at this point push the uppers together so the shoes push the self adjuster tight and try to fit drum back on

if its a tight fit remove adjuster and wind in. if very slack wind adjuster out so shoes just catch drum when re fitting....

now re fit upper spring...

then drum and torx screws

now to re adjust the shoes

climb into car carefully so as not to upset it on the jack

pump brakes slowly and listen for the clicks of the auto adjuster might take 50 or so pumps once it stops clicking it should be fully adjusted.....

then check handbrake operation and foot brake with a friend spinning hub

re fit wheel and torque up wheel nuts