I have many little projects I've picked up and not yet finished so I though I'd try to post some on here in case they're of any interest.

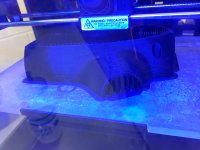

At my work we have inherited a 3D printer. It's not the best and it's not the fastest, but because it can't build high strength parts no-one is very keen on using it, so I have been 'practising'

It uses PLA in a strimmer wire type format. PLA is lower temperature than ABS, but it can be sanded which makes post processing available.

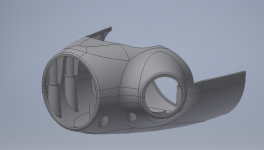

First off I want to make something to hold my Bluetooth speaker. It used to sit in the glove box, but it takes up room so I though it could fit underneath instead.

I designed 2 plastic arms that slot into the air vent at the rear of the speaker. There is access to the buttons on the top and the speaker can be easily removed for charging.

At my work we have inherited a 3D printer. It's not the best and it's not the fastest, but because it can't build high strength parts no-one is very keen on using it, so I have been 'practising'

It uses PLA in a strimmer wire type format. PLA is lower temperature than ABS, but it can be sanded which makes post processing available.

First off I want to make something to hold my Bluetooth speaker. It used to sit in the glove box, but it takes up room so I though it could fit underneath instead.

I designed 2 plastic arms that slot into the air vent at the rear of the speaker. There is access to the buttons on the top and the speaker can be easily removed for charging.