Abarth L

New member

- Joined

- Apr 9, 2010

- Messages

- 136

- Points

- 32

So luckily I were just leaving the yard still slow in 1st gear when the gearbox mounting broke "again"

So covering 3 subjects:

1. Is this a problem on the Stilo Abarth's?

2. Bad design, rediciouless amount of play.

3. Never try to do a modification.

1. At about 252000km mark going around a traffic circle the bolt from the gearbox bracket to the mounting broke.

I was not driving and out of country so the car was taken via low bed to exhaust and shock repair service centre, they put in a new bolt and that was it I thought.

During the engine rebuild when dismantling I noticed the thread is damaged "seized" so I opted to drill a mm bigger, tap the threat and put in a bigger bold. (Since a new one from FIAT has a 4 week delivery from Europe)

Well it lasted till now about 2200km's I were lucky, CV pulled out and except for engine top cover damage and MAF plug pulling out no other damage. (I did change the engine side mounting during the rebuild)

So is this common for the Stilo Abarth bolt to brake or pull out?

2. Both my Stilo Abarth's had a "loose" feeling somewhere in the suspension front "I thought" during quick acceleration and immediate throttle pull back.

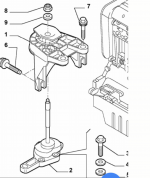

From the images below you will see the amount of play between the bolt and the body mounting bracket. I thought initially the guys forgot to put back a bush but after looking at google and visiting scrap yards yesterday found it is standard from the factory like that

So when putting the motor in 2200km's ago I made a small bush to try to eliminate some of the excessive play.

So this time I made a "bush" with very little play and like in "WoW"

What a difference it made in overall vibration etc, much stiffer and feel like a new modern car.

What are your experience and is this standard everywhere that there is so much play?

Also why does the gearbox mounting only use 3 bolts to tie down, looks like an after thought from FIAT.

Spoken to CV place this morning since I had to re-strap the boot rubbers and do wheel alignment again. The owner told me especially the Fiat 500 Abarth comes in a lot due to gearbox mounting failures, but they brake bad...

3. Well since this combination of mounting carry a lot of weight and the bottom (gearbox bracket) is made from puter it can't be modified.

I tried first drill a bit bigger and re tap FAILED.

Then I wonder what if I bypass the threat issue and drill a hole through so the bolt head carry the weight.. FAILED

So after sourcing a second hand bottom unit from a scrapyard I just removed the thick washer, so I can use "new" threat and be able to add another nut for more grip.

So covering 3 subjects:

1. Is this a problem on the Stilo Abarth's?

2. Bad design, rediciouless amount of play.

3. Never try to do a modification.

1. At about 252000km mark going around a traffic circle the bolt from the gearbox bracket to the mounting broke.

I was not driving and out of country so the car was taken via low bed to exhaust and shock repair service centre, they put in a new bolt and that was it I thought.

During the engine rebuild when dismantling I noticed the thread is damaged "seized" so I opted to drill a mm bigger, tap the threat and put in a bigger bold. (Since a new one from FIAT has a 4 week delivery from Europe)

Well it lasted till now about 2200km's I were lucky, CV pulled out and except for engine top cover damage and MAF plug pulling out no other damage. (I did change the engine side mounting during the rebuild)

So is this common for the Stilo Abarth bolt to brake or pull out?

2. Both my Stilo Abarth's had a "loose" feeling somewhere in the suspension front "I thought" during quick acceleration and immediate throttle pull back.

From the images below you will see the amount of play between the bolt and the body mounting bracket. I thought initially the guys forgot to put back a bush but after looking at google and visiting scrap yards yesterday found it is standard from the factory like that

So when putting the motor in 2200km's ago I made a small bush to try to eliminate some of the excessive play.

So this time I made a "bush" with very little play and like in "WoW"

What a difference it made in overall vibration etc, much stiffer and feel like a new modern car.

What are your experience and is this standard everywhere that there is so much play?

Also why does the gearbox mounting only use 3 bolts to tie down, looks like an after thought from FIAT.

Spoken to CV place this morning since I had to re-strap the boot rubbers and do wheel alignment again. The owner told me especially the Fiat 500 Abarth comes in a lot due to gearbox mounting failures, but they brake bad...

3. Well since this combination of mounting carry a lot of weight and the bottom (gearbox bracket) is made from puter it can't be modified.

I tried first drill a bit bigger and re tap FAILED.

Then I wonder what if I bypass the threat issue and drill a hole through so the bolt head carry the weight.. FAILED

So after sourcing a second hand bottom unit from a scrapyard I just removed the thick washer, so I can use "new" threat and be able to add another nut for more grip.

Attachments

-

001.JPG40.6 KB · Views: 67

001.JPG40.6 KB · Views: 67 -

002.JPG92.1 KB · Views: 76

002.JPG92.1 KB · Views: 76 -

2.JPG50.6 KB · Views: 69

2.JPG50.6 KB · Views: 69 -

004.JPG87.5 KB · Views: 75

004.JPG87.5 KB · Views: 75 -

005.JPG93.6 KB · Views: 68

005.JPG93.6 KB · Views: 68 -

019.JPG22.8 KB · Views: 72

019.JPG22.8 KB · Views: 72 -

16.JPG34.5 KB · Views: 73

16.JPG34.5 KB · Views: 73 -

15.JPG50.7 KB · Views: 65

15.JPG50.7 KB · Views: 65 -

010.JPG32.6 KB · Views: 66

010.JPG32.6 KB · Views: 66 -

5.JPG77.9 KB · Views: 60

5.JPG77.9 KB · Views: 60 -

25.JPG32.2 KB · Views: 89

25.JPG32.2 KB · Views: 89 -

23.JPG47.4 KB · Views: 76

23.JPG47.4 KB · Views: 76 -

22.JPG46.6 KB · Views: 56

22.JPG46.6 KB · Views: 56 -

21.JPG41.2 KB · Views: 55

21.JPG41.2 KB · Views: 55 -

20.JPG104.7 KB · Views: 76

20.JPG104.7 KB · Views: 76 -

26.JPG46.7 KB · Views: 79

26.JPG46.7 KB · Views: 79 -

27.JPG55.1 KB · Views: 67

27.JPG55.1 KB · Views: 67

Last edited: