I had a play at removing rust by electrolisis.

A plastic bucket, a 12v battery charger, sode washing soda and a sacrificial annode (lump of scrap iron) and we're in business.

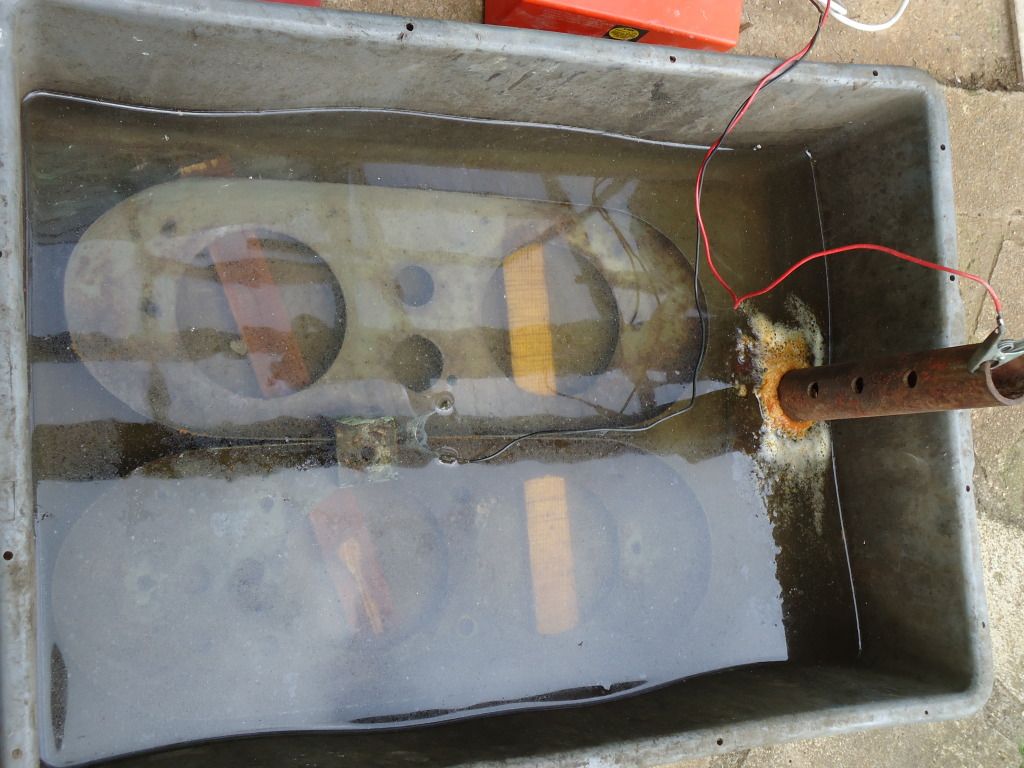

The pic show my 1st effort on 2 CA dash's after they had been bubbling for about 2 hours.

The positive lead goes to the lump of old iron and the negative to what you want to de-rust.

Fill your non conductive container with water and add a tablespoon of soda per gallon.Mix well.

connect up your leads, don't let the diode directly touch your work piece, plug in, and Bob's yer Auntie (as they say in the gender re-asignment trade)

After a mere 24 hours or more, the rust will magically detach itself from the job and travel in a straight line to you sacrificial doobrie and stick to that.

After a day or so (remembering not to switch off the power to the shed when you turn the lights out) this is what it all looks like (after I've tripped over the blasted thing a couple of times) a messy rusty soup.

Remove you item, wash it in mums sink. I found this a very slow yet satifying method of removing corrosion with minimal damage to the item. Very successful in all.

An amusing trade off is that if you then tip the water onto your lawn, worms will appear like small rockets bursting out of the ground. I don't know if there is some residual electricity, or the soda or what, but boy does it get the to appear. I mention this only so that we can all win that annual worm charming competition where people normally sing, chant and dance to attract the slithery little blighters. (I kid you not; this is England after all)

..