You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Punto 75 re-profiled camshaft timing

- Thread starter DimSei

- Start date

Currently reading:

Technical Punto 75 re-profiled camshaft timing

At standart timing marks the car goes worse than a stock seicento. I have tried many timings such as +6 +12 +18 +24 and the best seems to be at +24. At least the 0-100km/h show the best results in that timing. BUT not sure if that is the best for this camshaft.

Cheers

Cheers

If it is just reprofiled, then it shouldn't be that far different from a stock punto 75 camshaft as you can only change so much???

What is the spec of the rest of your engine? Do you have a reprogrammable ecu?

What is the spec of the rest of your engine? Do you have a reprogrammable ecu?

- Joined

- May 1, 2020

- Messages

- 28

- Points

- 61

It's either to have timing events and a degree wheel or trial end error.

Who reprofiled the cam? They should give you the details of how to degree it.

You'll need a degree wheel, dti and a pointer.

I've got a reprofiled 866 cam, done by Piper to a 285 spec but I don't have any detailed from Piper, and when I asked them, they were no help.....but they could measure it for me it came unused with an engine I bought. I have since measured it so I'll try and dig them out

it came unused with an engine I bought. I have since measured it so I'll try and dig them out

You'll need a degree wheel, dti and a pointer.

I've got a reprofiled 866 cam, done by Piper to a 285 spec but I don't have any detailed from Piper, and when I asked them, they were no help.....but they could measure it for me

- Joined

- Feb 28, 2016

- Messages

- 861

- Points

- 235

hi Dimsei

Just checking you have reset all the valve clearances etc from the settings you had before the cam was reground. have you had any of the injection system reset since its fitting.

ideally yes you need a degree wheel and a dial gauge would be helpful.

its also helpful to have to have the other numbering ie 33 77 77 33 so you can work out the max lift point.

Tim

Just checking you have reset all the valve clearances etc from the settings you had before the cam was reground. have you had any of the injection system reset since its fitting.

ideally yes you need a degree wheel and a dial gauge would be helpful.

its also helpful to have to have the other numbering ie 33 77 77 33 so you can work out the max lift point.

Tim

The Piper reground cam i have has a max lift of 10.18mm

The 866 cam I had has a max lift of 9.48mm

As you can't add material to the lobe, the extra lift comes from grinding the base circle diameter down.....in my case by 0.6mm. As the above post states, this has to be taken up with thicker shims, although mine did have smaller bucket shims fitted and top hat shims to take up the difference. I have now converted it to use solid lifters and top hat shims.

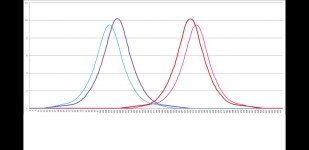

I'll upload a graph of mine when I'm out of work

The 866 cam I had has a max lift of 9.48mm

As you can't add material to the lobe, the extra lift comes from grinding the base circle diameter down.....in my case by 0.6mm. As the above post states, this has to be taken up with thicker shims, although mine did have smaller bucket shims fitted and top hat shims to take up the difference. I have now converted it to use solid lifters and top hat shims.

I'll upload a graph of mine when I'm out of work

hi Dimsei

its also helpful to have to have the other numbering ie 33 77 77 33 so you can work out the max lift point.

Tim

The shop that reprofiled it said it is 40/80 in/ex and full lift at 110 degrees.

So what should i do now with those numbers?

Sorry for not having that much knowledge on timing.

The Piper reground cam i have has a max lift of 10.18mm

The 866 cam I had has a max lift of 9.48mm

As you can't add material to the lobe, the extra lift comes from grinding the base circle diameter down.....in my case by 0.6mm.

I'll upload a graph of mine when I'm out of work

To me it seems to be 0.7mm for you. Also, i need to recheck the clearenses because i dont see any bigger difference than the stock sei with a p75 camshaft on it.

Also thanks for the graphs.

Whats your power output on that setup?

I am planning on remapping the 4AF ecu soon on the other week. Hope to see over 80chp. Otherwise, with 40mm TB P75 Intake manifold Full Decat 4-2-1 exhaust and higher CR and over 1000€ spent on that mod are going to be the worst loss, or some 16v setups are going to be worried. :slayer:

- Joined

- Feb 28, 2016

- Messages

- 861

- Points

- 235

Hi Dimsei

having the 40/80 numbers allows you to work out the 110 degrees but you have that too.

So, you need to set the camshaft position, so the position you need is the point at which the inlet valve on cylinder 1 is maximum open, this is done with a dial gauge, once you have set this you will need to rotate the crankshaft so that the crankshaft is 110 degrees after top dead center.

this is at the point in the cycle where the inlet valve is open the most and the piston is going down sucking the fuel air mix into the cylinder.

if you look at KENT cams main web page and scroll right down to a section where it says updates(or something like), a few items into this there is a video of vulcan engineering setting the camshaft timing a very slightly different way but you can see how the dial gauges are used, its being done on a single overhead cam engine similar to yours.

remember never force anything as you may be bending valves or something like.

Tim

having the 40/80 numbers allows you to work out the 110 degrees but you have that too.

So, you need to set the camshaft position, so the position you need is the point at which the inlet valve on cylinder 1 is maximum open, this is done with a dial gauge, once you have set this you will need to rotate the crankshaft so that the crankshaft is 110 degrees after top dead center.

this is at the point in the cycle where the inlet valve is open the most and the piston is going down sucking the fuel air mix into the cylinder.

if you look at KENT cams main web page and scroll right down to a section where it says updates(or something like), a few items into this there is a video of vulcan engineering setting the camshaft timing a very slightly different way but you can see how the dial gauges are used, its being done on a single overhead cam engine similar to yours.

remember never force anything as you may be bending valves or something like.

Tim

- Joined

- Feb 28, 2016

- Messages

- 861

- Points

- 235

Hi Dimsei

you can get Dial gauge on ebay for £15 and a stand for about the same, sometimes the whole lot can be in one pack.

and the camshaft degree discs can be found for under £10 delivered

Tim

you can get Dial gauge on ebay for £15 and a stand for about the same, sometimes the whole lot can be in one pack.

and the camshaft degree discs can be found for under £10 delivered

Tim

- Joined

- Feb 28, 2016

- Messages

- 861

- Points

- 235

Hi Again

pay close attention to the video and see what he uses

Tim

pay close attention to the video and see what he uses

Tim