Well, my boy finally found time to let me get on with those front brakes. Last summer, when I serviced it, I noticed the front brake pads were getting a bit "skinny" and, although the car only does around 15 miles a day taking him to his work in the town centre and home again, I suggested renewing them. When he bought this car back in 2018 I did an end to end check of it and noticed the discs and pads were new at that time. Now, the discs were just about serviceable but not pristine and when I inquired about prices at SRS it seemed only common sense to do the discs too, so I bought both discs and a set of pads for £68 and a few "p" all in. This is the first NAPA branded brake parts I've bought and they look to be of good quality so it's going to be interesting to see how they do in service.

The strip down went well at first with the 7mm Allen headed slider pins coming out without too much of a struggle, the calipers being easily lifted away and the caliper pistons easily being pushed back into their housings. Great, no caliper problems then! the two outer pads were reluctant to come off the caliper casting but a wee bit of a tap with a hammer soon had them off. the inner ones are retained in the hollow piston with spring clips on the pad backing and come out easily - although I later discovered persuading the new ones back into the pistons was a bit of a struggle!

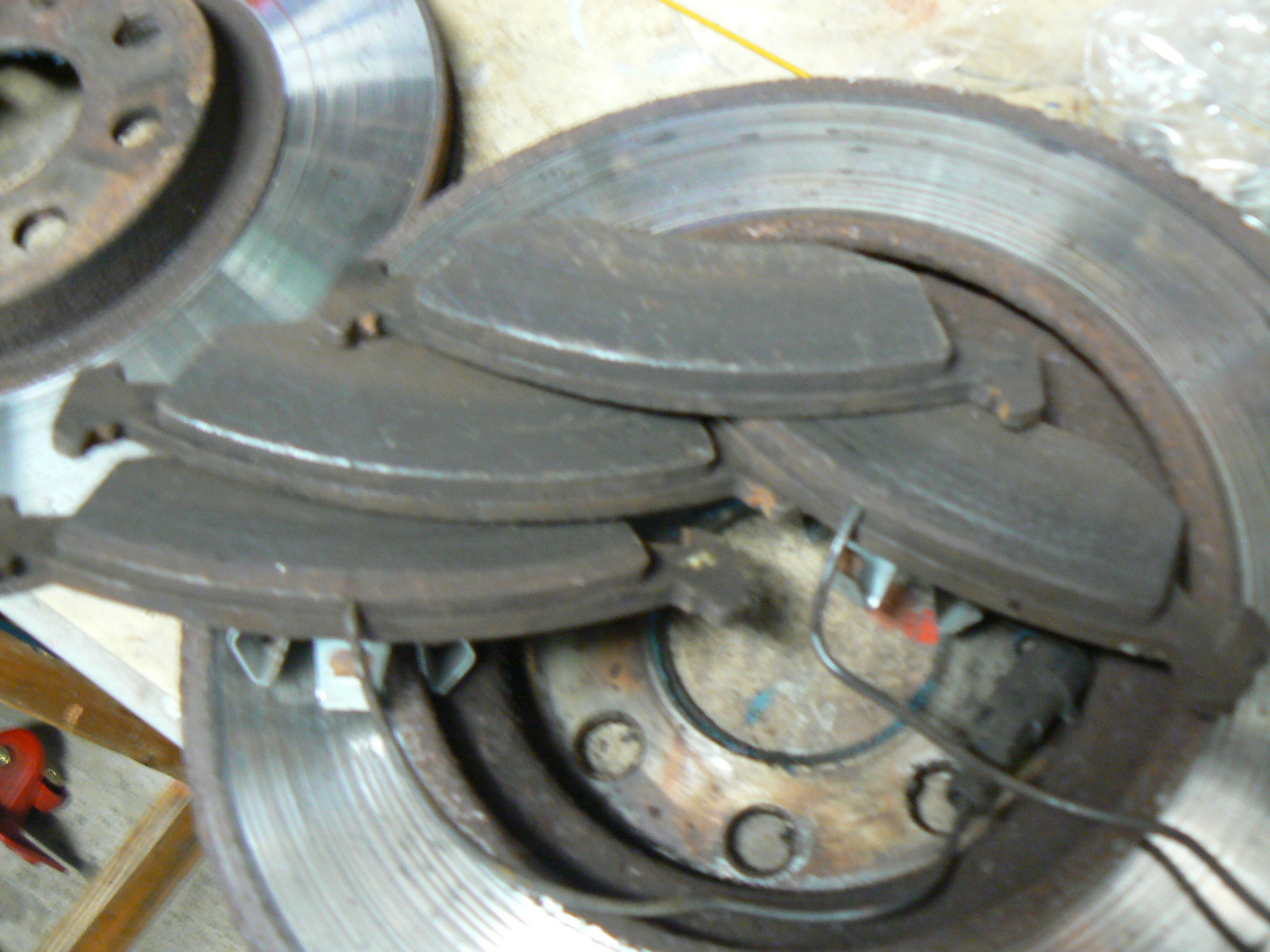

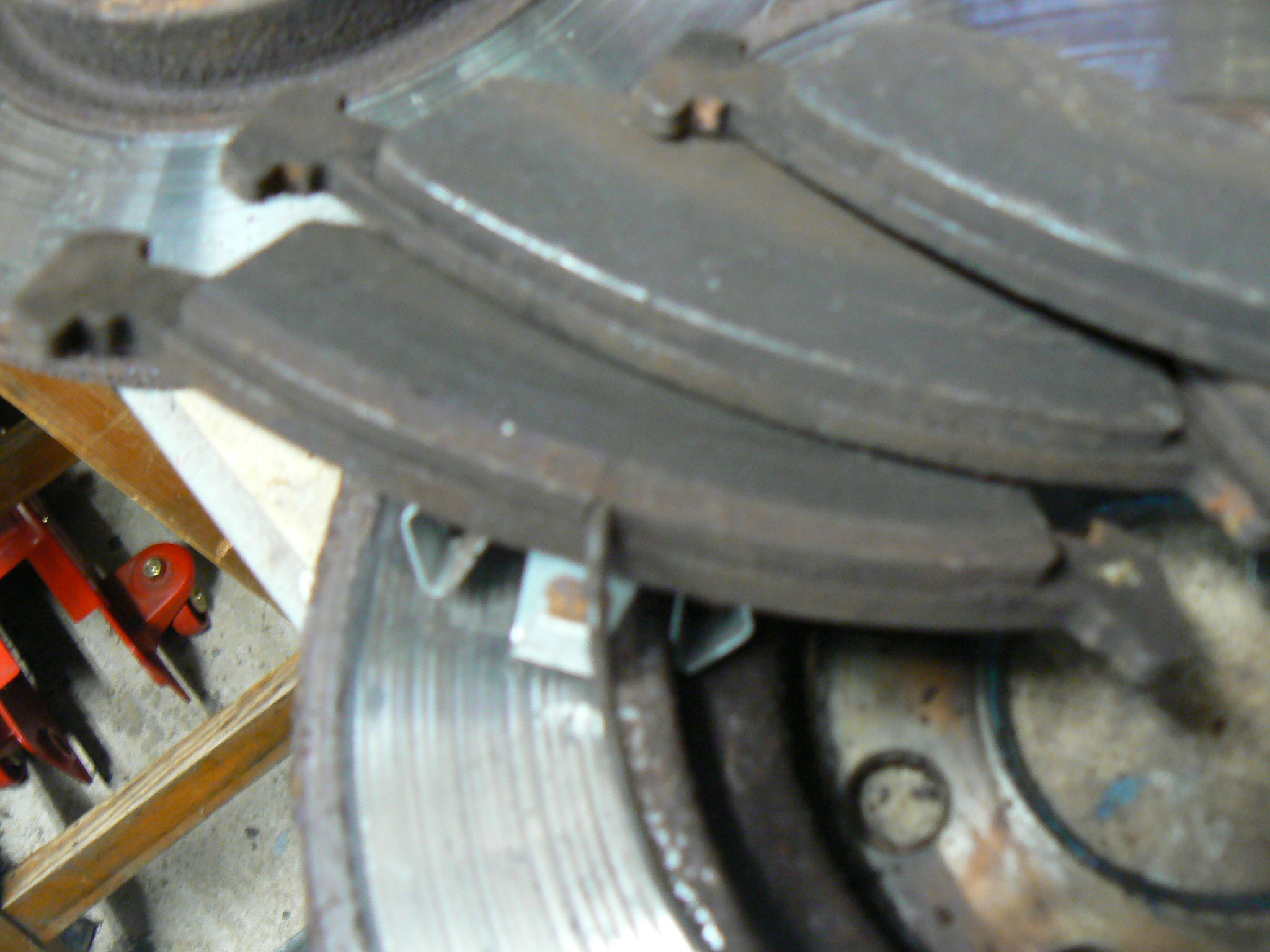

Looking at the pads they had about 2 mm still on them and were showing no signs of separating from the metal backings:

closer examination of the N/S/F inner pad shows it was just about to break through into the depth warning wire:

Unfortunately this wouldn't have done him much good as the wire to that sensor, on the vehicle side of the plug, is broken off. I found this at the summer service and asked Kenny - he of Fiat indy fame - whether this was MOT failable. It's not and the repair looks awkward as the wire has snapped off inside the molding of the plug leaving no wire "tail" to solder too. So, in the meantime I've just taped off the plug and cable tied it out of the way. In fact I think I'll just leave it that way as I'm going to catch pad wear at service intervals anyway. Note to self. Find out if there's an alternative pad available without the warning wires. I've had this in the past and found a considerable saving can be made. Wouldn't affect the warning light either as it only comes on when the wire is earthed - by touching the disc.

All good so far then, now to remove the caliper carriers - held on with "silly" Torx bolts. Luckily I have a set of female Torx sockets so this should be easy? However the heads of the bolts are VERY crusty with rust. So crusty in fact that I at first thought they'd take an E18 socket, which I had to hammer on over the rust. but it went on and felt quite firm. Put my power bar on it and heaved. Oh dear, great big crunch and I think I've rounded it off! Well, it does look rounded, but no, maybe not? Let's try the next size down - E16. Several strokes of the hammer needed to seat it, but actually it seems to have gone on pretty well. So I knocked it sideways off again, take a look at the bolt head, and realize that E16 is actually the right size, it was just the crusty rust which was fooling me. Ok, back in we go with the powerbar on the socket and, Oh dear, this is so tight. I could put a length of scaffold bar on it but I don't want to round it. Then I realise the shape of the Torx bolt head and the E16 socket are such that if I use the Vibroshock tool it can transmit the shock loads directly into the bolt. So this is an ideal job for Vibroshock! Here is the socket assembled onto the tool:it is ready to fit to the air hammer:

and here's the whole shebang ready for action:

Gave it a good rattling, less than a minute, and the bolt comes free quite easily. Hurrah!

All 4 bolts were in similar condition, were given the same treatment and all came out not much the worse for wear.

Each discs is retained to it's hub with two small torx countersunk screws, 3 of which came out quite easily but one needed the vibro treatment and the discs nearly fell off by themselves. The previous ones having been treated to some copa slip by whoever fitted them.

Now on the bench I could see that deciding to renew the discs was definitely the right course of action. Although looking not too bad on the front - outer - faces, bit of surface unevenness and some rust on the edges of the pad contact face:

The inner faces were somewhat worse with deeper scoring and more rust, some actually beginning to reducing the effective pad contact area:

If money had been a critical factor I think you could have just done pads without changing the discs and I'm sure it would have reached braking figures which would have satisfied the MOT - Due next month - but a year or so down the line? No, better just to do the discs too. Also there's one very long and steep hill - Church Hill - on his route to work which gives the brakes a good work out.

It all went back together well - hub faces cleaned and discs degreased and checked for runout, then some blue thread locker on the carrier bolts, more to keep the moisture out of the threads than anything else and torque wrench used on them too. Some ceramic grease on the pad slides and silicon grease on the caliper retaining pins as they "live" in rubber tubes.

On the road test I noticed there's a slight clutch judder developing which wasn't there in the summer (new clutch about 3, maybe 4 years ago and my boy isn't a clutch killer - 1st motion shaft seal? oh I hope not) and the mileage display is flashing all the time. Going to check the battery condition, but it was a new battery about 2 or 3 years ago so shouldn't be that. I'm fearing it's going to be something to do with the Body Control Module which frightens me. I may have to learn how to do more "stuff" (proxi alignment?) with my MES? Kenny's foreman says he'd just let it flash if it was him!

No rest for the "wicked" eh? Still, the brakes are really silky smooth now!

The strip down went well at first with the 7mm Allen headed slider pins coming out without too much of a struggle, the calipers being easily lifted away and the caliper pistons easily being pushed back into their housings. Great, no caliper problems then! the two outer pads were reluctant to come off the caliper casting but a wee bit of a tap with a hammer soon had them off. the inner ones are retained in the hollow piston with spring clips on the pad backing and come out easily - although I later discovered persuading the new ones back into the pistons was a bit of a struggle!

Looking at the pads they had about 2 mm still on them and were showing no signs of separating from the metal backings:

closer examination of the N/S/F inner pad shows it was just about to break through into the depth warning wire:

Unfortunately this wouldn't have done him much good as the wire to that sensor, on the vehicle side of the plug, is broken off. I found this at the summer service and asked Kenny - he of Fiat indy fame - whether this was MOT failable. It's not and the repair looks awkward as the wire has snapped off inside the molding of the plug leaving no wire "tail" to solder too. So, in the meantime I've just taped off the plug and cable tied it out of the way. In fact I think I'll just leave it that way as I'm going to catch pad wear at service intervals anyway. Note to self. Find out if there's an alternative pad available without the warning wires. I've had this in the past and found a considerable saving can be made. Wouldn't affect the warning light either as it only comes on when the wire is earthed - by touching the disc.

All good so far then, now to remove the caliper carriers - held on with "silly" Torx bolts. Luckily I have a set of female Torx sockets so this should be easy? However the heads of the bolts are VERY crusty with rust. So crusty in fact that I at first thought they'd take an E18 socket, which I had to hammer on over the rust. but it went on and felt quite firm. Put my power bar on it and heaved. Oh dear, great big crunch and I think I've rounded it off! Well, it does look rounded, but no, maybe not? Let's try the next size down - E16. Several strokes of the hammer needed to seat it, but actually it seems to have gone on pretty well. So I knocked it sideways off again, take a look at the bolt head, and realize that E16 is actually the right size, it was just the crusty rust which was fooling me. Ok, back in we go with the powerbar on the socket and, Oh dear, this is so tight. I could put a length of scaffold bar on it but I don't want to round it. Then I realise the shape of the Torx bolt head and the E16 socket are such that if I use the Vibroshock tool it can transmit the shock loads directly into the bolt. So this is an ideal job for Vibroshock! Here is the socket assembled onto the tool:it is ready to fit to the air hammer:

and here's the whole shebang ready for action:

Gave it a good rattling, less than a minute, and the bolt comes free quite easily. Hurrah!

All 4 bolts were in similar condition, were given the same treatment and all came out not much the worse for wear.

Each discs is retained to it's hub with two small torx countersunk screws, 3 of which came out quite easily but one needed the vibro treatment and the discs nearly fell off by themselves. The previous ones having been treated to some copa slip by whoever fitted them.

Now on the bench I could see that deciding to renew the discs was definitely the right course of action. Although looking not too bad on the front - outer - faces, bit of surface unevenness and some rust on the edges of the pad contact face:

The inner faces were somewhat worse with deeper scoring and more rust, some actually beginning to reducing the effective pad contact area:

If money had been a critical factor I think you could have just done pads without changing the discs and I'm sure it would have reached braking figures which would have satisfied the MOT - Due next month - but a year or so down the line? No, better just to do the discs too. Also there's one very long and steep hill - Church Hill - on his route to work which gives the brakes a good work out.

It all went back together well - hub faces cleaned and discs degreased and checked for runout, then some blue thread locker on the carrier bolts, more to keep the moisture out of the threads than anything else and torque wrench used on them too. Some ceramic grease on the pad slides and silicon grease on the caliper retaining pins as they "live" in rubber tubes.

On the road test I noticed there's a slight clutch judder developing which wasn't there in the summer (new clutch about 3, maybe 4 years ago and my boy isn't a clutch killer - 1st motion shaft seal? oh I hope not) and the mileage display is flashing all the time. Going to check the battery condition, but it was a new battery about 2 or 3 years ago so shouldn't be that. I'm fearing it's going to be something to do with the Body Control Module which frightens me. I may have to learn how to do more "stuff" (proxi alignment?) with my MES? Kenny's foreman says he'd just let it flash if it was him!

No rest for the "wicked" eh? Still, the brakes are really silky smooth now!