- Joined

- Sep 14, 2004

- Messages

- 1,145

- Points

- 229

Hi all,

I've had some knocking and slight vague steering for a while but have just put up with it.

Well i've got some holiday coming so thought i'd enjoy myself and do some work on the stilo.

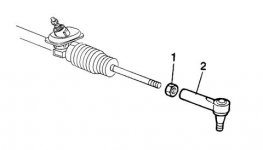

I've already got the droplinks ready to be changed but thought i'd also change the track rod ends at the same time if they are a DIY job.

I believe they are all the original parts, if not then they have definately covered 70,000 miles since i've had it so should be ready be changing, LOL

Can anyone write a step by step guide for me and include any specific tools required, i know i need to buy a balljoint splitter but anything else?

Should i use OE spec ones, such as

http://www.shop4parts.co.uk/index.cfm?action=catalogue.list

at £22 plus VAT

or have a chat with my local motor factor

Ta

I've had some knocking and slight vague steering for a while but have just put up with it.

Well i've got some holiday coming so thought i'd enjoy myself and do some work on the stilo.

I've already got the droplinks ready to be changed but thought i'd also change the track rod ends at the same time if they are a DIY job.

I believe they are all the original parts, if not then they have definately covered 70,000 miles since i've had it so should be ready be changing, LOL

Can anyone write a step by step guide for me and include any specific tools required, i know i need to buy a balljoint splitter but anything else?

Should i use OE spec ones, such as

http://www.shop4parts.co.uk/index.cfm?action=catalogue.list

at £22 plus VAT

or have a chat with my local motor factor

Ta

Last edited: