Maybe a silly suggestion, but any chance of back flushing through pump from the return to tank end of low pressure side of pump, so fuel runs out of that inlet pipe, maybe with a very gentle "twizzle" with a cotton bud to see if any particles dislodged could be examined, as you would be directing any debris out of the pump inlet side by that reverse action.

I wouldn't be tempted to leave the filter out as any debris must be very fine if it has already gone through a proper diesel fuel filter element on bulkhead.

We're both silly then...

that's much along the lines was thinking; although a different strategy.

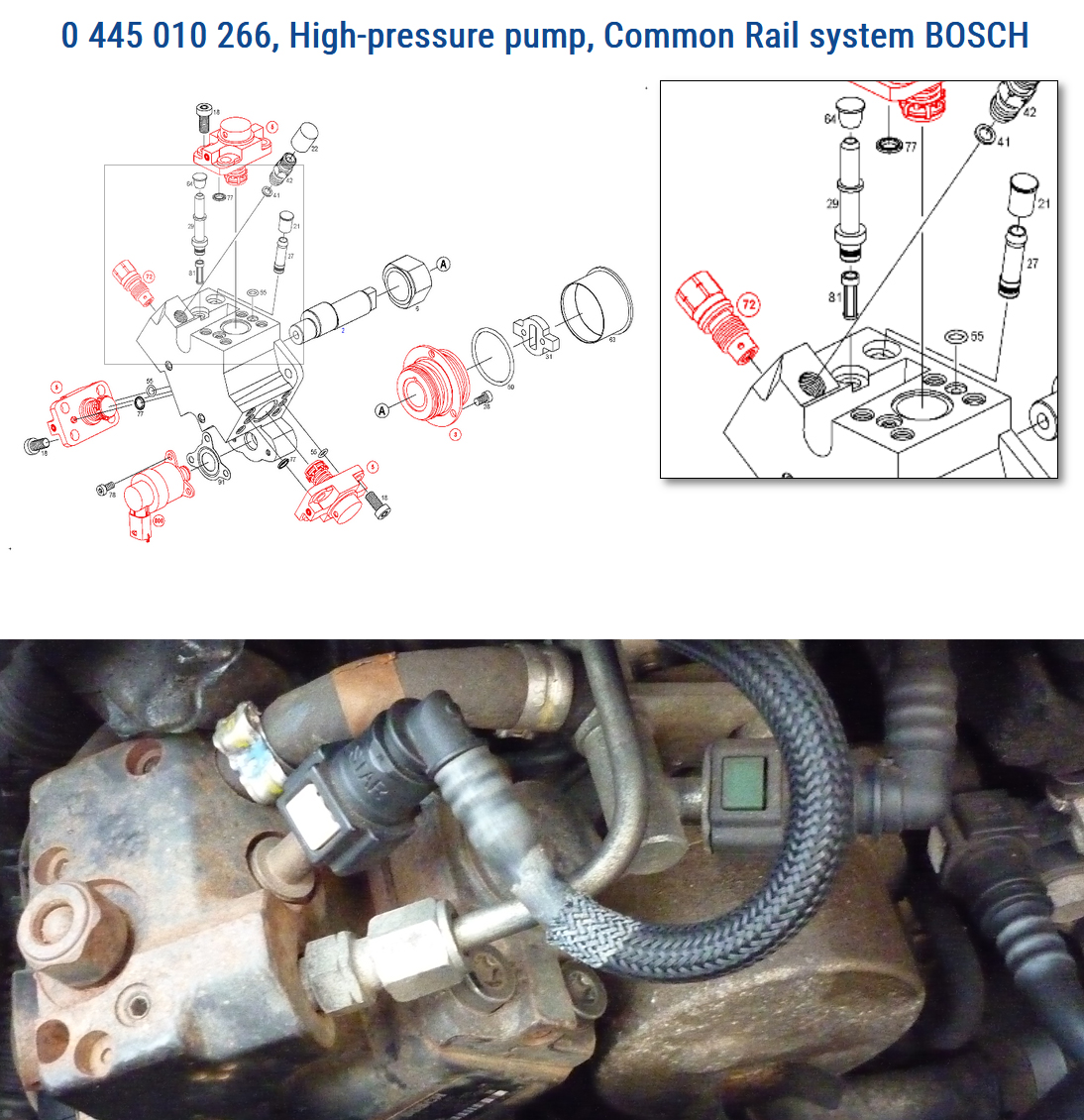

My thoughts at the moment in that regard are gravitating towards taking a syringe fitted with some fine pipe (and/or a wide bore needle) and trying to extract the 'contents' of the strainer. I would also like a sample from the inside of the strainer to examine. So I plan on:

1: Extracting whatever (if any) fluid I can from the pipe/strainer

2: Taking a sample swab

from inside the strainer in situ

3: Flushing out the area with some clean diesel - syringe, needle, rinse it out so the crud flushes out through the to end of the inlet pipe.

I wouldn't use a cotton bud - from experience of other systems this is something to be avoided as stray cotton fibres can cause havoc where things on the micro scale are concerned...

(For example - in the old days you 'might' clean the heads of a domestic VHS recorder with a cotton bud and alcohol, and would get away with it if you were good/careful knew what you were doing etc; but it was advised against. If you were dealing with something like an Mii machine which cost the price of a house (no, I'm not kidding!) in a broadcast environment, which had much finer tolerances you would only ever use the correct chamois cleaning sticks - for that reason! Post-mortem traces of cotton bud would be getting somebody their jotters! )

...Anyway; I digress.

Yes, 'whatever' that element is filtering, it must be very fine indeed. The new one just arrived. Overall it's just 20mm long, 5mm in diameter with the active 'screen' area being just 15mm, sealed at the end. I'm probably over-estimating the internal diameter as 4mm.

The overall internal volume of the filter is (at a generous estimate) <0.19ml - You can easily imagine that it wouldn't need to fill up with very much 'crud' to reduce that capacity dramatically! - You wouldn't actually get a cotton bud in there!

However... for various reasons (working on an assortment of very fine-scale mechanisms) I do have a supply of the soft disposable sampling swabs; of exactly the same kind you might recall were included as part of the COVID testing kits - Not only a safer bet but about the correct diameter and length to get down the inlet pipe and into the filter!

I might get a chance to do that this afternoon.