I used to get a bit of pinking on my 899 Cinq under full load at low-medium revs when it was using 95RON.As it somehow ran out of fuel today (seems the tank has a filling issue and when I thought it was full, it has only a gallon or so in it), I put v-power in. It now revs through the noise which is quite a bit quieter now and bounces off the limiter, boots to 50 in 2nd in a hurry.

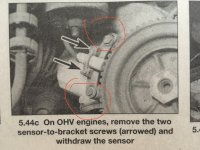

I'n confident it's a pre-ignition issue given that over-fuelling and higher octane fuel have improved the situation. I'm going to get new plugs in it and replace the crank sensor just for the hell of it.

I'm sure the ignition timing was a little too advanced.

The crank sensor is adjustable but the screws are tiny and old so I left that alone and ran it on Tesco 99RON instead and it ran very well on that.