Keith1950

Member

Hi All

Hope for some advice.

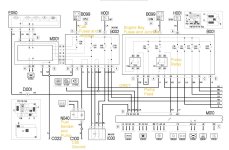

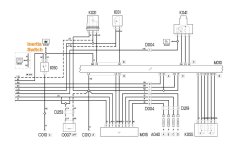

Since the last time I used my fiat motorhome 3ltr 2007 , a problem has appeared Fault code P0230 which points to fuel relay primary circuit

The vehicle will start but runs for about 40 seconds then cuts out .

I have swapped the relay out for a known good one , but to as the fuel pump is running and priming the fuel injector pump would this not mean that the relay is activating for that 40 seconds and then the engine management is losing the signal to keep pump going , are there any other things that might switch of the fuel pump relay ?

I will be going out to check on relay voltage and activation on Sunday but NY help would be welcome

Regards

Keith

Hope for some advice.

Since the last time I used my fiat motorhome 3ltr 2007 , a problem has appeared Fault code P0230 which points to fuel relay primary circuit

The vehicle will start but runs for about 40 seconds then cuts out .

I have swapped the relay out for a known good one , but to as the fuel pump is running and priming the fuel injector pump would this not mean that the relay is activating for that 40 seconds and then the engine management is losing the signal to keep pump going , are there any other things that might switch of the fuel pump relay ?

I will be going out to check on relay voltage and activation on Sunday but NY help would be welcome

Regards

Keith