The clutch mechanism is the hydraulic type with a common reservoir with the brake master cylinder.

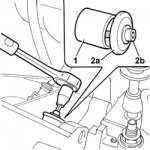

1. In order to extract the clutch lever pin, a tool has to be made cutting a

length of around 25 mm in length from a 26 mm diameter pipe.

2. Fit a suitable washer (2a) on the tool and tighten an M6x1 bolt (2b) at least 55 mm long in the pin housing.

- Tighten the tool produced for the pin removal and extract the shaft fixing the fork lever.

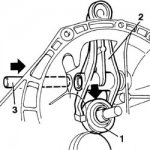

The engine needs a supporting bracket during gearbox removal. The crossmember does not have to be removed to get the gearbox out.

1. Place the bracket for supporting the power unit, fastened to the suspension crossmember and to the lower front crossmember, under the engine oil sump in a central position.

2. In order to be able to position the crossmember correctly and safely, the corners of the ends of the actual crossmember bracket at the two ends have to be modified making sure that they match correctly with the front crossmember and the suspension crossmember.

Hope this helps

Cheers