You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical 3ltr throttle body

- Thread starter Localdave

- Start date

Currently reading:

Technical 3ltr throttle body

- Joined

- Nov 3, 2014

- Messages

- 822

- Points

- 282

Hi

What prompted you to have a new throttle body fitted ?

What is the fault code (I assume it was reset after new TB fitted but has come back) ?

What prompted you to have a new throttle body fitted ?

What is the fault code (I assume it was reset after new TB fitted but has come back) ?

- Joined

- Nov 3, 2014

- Messages

- 822

- Points

- 282

Hi

Yes, the later TBs need an adaptor cable.

The engine light will eventually go out, but it may take 5 or 6 successful cold starts before the software decides that the fault is no longer present and resets it.

A fault code will still be lodged in the ECU memory. This will remain stored until it is cleared, if you ask a garage nicely they can do this.

Yes, the later TBs need an adaptor cable.

The engine light will eventually go out, but it may take 5 or 6 successful cold starts before the software decides that the fault is no longer present and resets it.

A fault code will still be lodged in the ECU memory. This will remain stored until it is cleared, if you ask a garage nicely they can do this.

Hi

Thanks for your help so far!!!!! however had new febi TB and Febi cable connector, Light still on and now in limp mode ok on level struggling up hill .

Any help would be very much appreciated.

Strange thing is if we connect the old TB light goes out!!!!!!

It has been suggested to me that the Febi TB is faulty.

Regards

Dave

Thanks for your help so far!!!!! however had new febi TB and Febi cable connector, Light still on and now in limp mode ok on level struggling up hill .

Any help would be very much appreciated.

Strange thing is if we connect the old TB light goes out!!!!!!

It has been suggested to me that the Febi TB is faulty.

Regards

Dave

- Joined

- Nov 3, 2014

- Messages

- 822

- Points

- 282

Hi

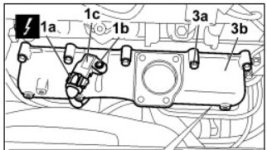

If it helps, here is some background on the Ducato Throttle body. The TB flap is partially closed by the ECU to create a lower pressure in the inlet manifold under certain engine operating conditions, to encourage the flow of recirculated exhaust gas from the EGR when needed. It also closes briefly during engine shutdown, to discourage shudder.

The TB assemblies for the 3.0 Litre and 2.3 Litre engines are a different shape, but operate in the same way. There are only 3 wires to the unit, via a 4 pin connector on the original fitment:

Pin 1 Grey/Black Pulsed signal from ECU Connector A Pin 15. The pulse width sets the position of the Flap.

Pin 2 Blue/Grey +12 Volt supply from Fuse F11 (Shared with other components)

Pin 3 Brown/Green Ground

Pin 4 Not Used

Later TBs may have a 6 pin connector, so need a short 3 wire adaptor cable to mate with the existing loom

Pin 1 Pink Pulsed Signal

Pin 2 Yellow Ground

Pin 3 Not Used

Pin 4 Not Used

Pin 5 No Pin Fitted

Pin 6 White +12 Volt Supply

Note that these colours are for a Marelli adaptor, yours may be different

Note that Fiat do not use any direct position feedback from the TB flap. It is just assumed that it "does what it is told". I suspect that the ECU performs a calculation on the data from other engine sensors to determine indirectly whether the TB is working properly. If one of these sensors (e.g. Manifold Absolute Pressure) is faulty it could be misinterpreted as a TB fault.

It would be helpful if you could find out the error code(s) logged in memory, by connecting a fault code reader to the OBD II socket (Next to the fuses under the dashboard, drivers side).

I also suggest you double check that fuse F11 (in the engine bay fusebox) hasn't blown. One of the components this fuse supplies is the oil vapour heater. These are known to go short-circuit and take out the fuse. This small heater (it's inside a fume breather hose) may be safely left disconnected unless you live in a very cold climate.

If it helps, here is some background on the Ducato Throttle body. The TB flap is partially closed by the ECU to create a lower pressure in the inlet manifold under certain engine operating conditions, to encourage the flow of recirculated exhaust gas from the EGR when needed. It also closes briefly during engine shutdown, to discourage shudder.

The TB assemblies for the 3.0 Litre and 2.3 Litre engines are a different shape, but operate in the same way. There are only 3 wires to the unit, via a 4 pin connector on the original fitment:

Pin 1 Grey/Black Pulsed signal from ECU Connector A Pin 15. The pulse width sets the position of the Flap.

Pin 2 Blue/Grey +12 Volt supply from Fuse F11 (Shared with other components)

Pin 3 Brown/Green Ground

Pin 4 Not Used

Later TBs may have a 6 pin connector, so need a short 3 wire adaptor cable to mate with the existing loom

Pin 1 Pink Pulsed Signal

Pin 2 Yellow Ground

Pin 3 Not Used

Pin 4 Not Used

Pin 5 No Pin Fitted

Pin 6 White +12 Volt Supply

Note that these colours are for a Marelli adaptor, yours may be different

Note that Fiat do not use any direct position feedback from the TB flap. It is just assumed that it "does what it is told". I suspect that the ECU performs a calculation on the data from other engine sensors to determine indirectly whether the TB is working properly. If one of these sensors (e.g. Manifold Absolute Pressure) is faulty it could be misinterpreted as a TB fault.

It would be helpful if you could find out the error code(s) logged in memory, by connecting a fault code reader to the OBD II socket (Next to the fuses under the dashboard, drivers side).

I also suggest you double check that fuse F11 (in the engine bay fusebox) hasn't blown. One of the components this fuse supplies is the oil vapour heater. These are known to go short-circuit and take out the fuse. This small heater (it's inside a fume breather hose) may be safely left disconnected unless you live in a very cold climate.

Hi

Again thanks for your help. I'm deff not techy when it comes to electrics. I have checked the fuse F11 all ok. The connector for the Febi has a 4 pins but only 3 are used.

Do you think it may be worth fitting a new manifold absolute pressure sensor?

Again thanks for your help. I'm deff not techy when it comes to electrics. I have checked the fuse F11 all ok. The connector for the Febi has a 4 pins but only 3 are used.

Do you think it may be worth fitting a new manifold absolute pressure sensor?

LandyAndy

Member

If the light goes out with old sensor connected, it makes me think the fault lays either with the new TB, or the loom that swaps old to new.

yes will be phoning Febi up tomorrow and will try to get replacements. I have checked wiring in as much as seeing if there is any obvious break checked fuse F11 so may be it is as you say a faulty TB or loom or both!!!!!If the light goes out with old sensor connected, it makes me think the fault lays either with the new TB, or the loom that swaps old to new.

- Joined

- Nov 3, 2014

- Messages

- 822

- Points

- 282

Hi

The combined MAP and Intake Air Temp sensor K044 pokes into the top of the inlet manifold with an O-ring seal, they have a tiny hole to communicate pressure to the sensor inside, and this is vulnerable to blockage from the oil/soot that always builds up over time in the intake manifold.

I don't normally advocate changing parts until they are proven guilty, but these sensors are only about £40 so it could be worth a gamble. Should be an easy swap (one connector, one bolt) but I don't know if you also have to take off the TB and/or its elbow pipe to get enough clearance.

It does seem odd that the old and new TBs are behaving differently though. What fault code are you getting ?

The combined MAP and Intake Air Temp sensor K044 pokes into the top of the inlet manifold with an O-ring seal, they have a tiny hole to communicate pressure to the sensor inside, and this is vulnerable to blockage from the oil/soot that always builds up over time in the intake manifold.

I don't normally advocate changing parts until they are proven guilty, but these sensors are only about £40 so it could be worth a gamble. Should be an easy swap (one connector, one bolt) but I don't know if you also have to take off the TB and/or its elbow pipe to get enough clearance.

It does seem odd that the old and new TBs are behaving differently though. What fault code are you getting ?

Attachments

error code P0638 from memoryHi

The combined MAP and Intake Air Temp sensor K044 pokes into the top of the inlet manifold with an O-ring seal, they have a tiny hole to communicate pressure to the sensor inside, and this is vulnerable to blockage from the oil/soot that always builds up over time in the intake manifold.

I don't normally advocate changing parts until they are proven guilty, but these sensors are only about £40 so it could be worth a gamble. Should be an easy swap (one connector, one bolt) but I don't know if you also have to take off the TB and/or its elbow pipe to get enough clearance.

It does seem odd that the old and new TBs are behaving differently though. What fault code are you getting ?

LandyAndy

Member

That’s the same code I get when I unplug my TB and it then also puts it to limited power.

- Joined

- Nov 3, 2014

- Messages

- 822

- Points

- 282

Hi

P0638 is a generic fault code relating to the performance of the Throttle Body. Fiat have chosen to use it but the exact meaning they have allocated it it is down to them and I don't have that detailed information.

My best guess is that either an electrical/wiring fault has been detected OR the ECU has determined by indirect means that the TB isn't doing what it should, e.g. it is jammed in position or sticky in operation.

The problem with fault codes is that they are only a guide to the area where one should be looking, and diagnostics should be backed up by other tests and experience. There have been instances in the past where people have wasted time looking only for wiring problems when the fault lay elsewhere.

P0638 is a generic fault code relating to the performance of the Throttle Body. Fiat have chosen to use it but the exact meaning they have allocated it it is down to them and I don't have that detailed information.

My best guess is that either an electrical/wiring fault has been detected OR the ECU has determined by indirect means that the TB isn't doing what it should, e.g. it is jammed in position or sticky in operation.

The problem with fault codes is that they are only a guide to the area where one should be looking, and diagnostics should be backed up by other tests and experience. There have been instances in the past where people have wasted time looking only for wiring problems when the fault lay elsewhere.

LandyAndy

Member

My understanding of the Fiat system is that even if the throttle body wasn’t doing what it should the system doesn’t know this as it doesn’t check it. That is why only three of the connections are used. if you jam the TB whilst it is trying to operate it doesn’t cause an error.

spoke to Febi technical this morning who told me to folllow a certain procedure:

SELF LEARNING: If the throttle body is installed in the vehicle, do not start the engine immediately! The first operation should be: 1. Turn on the key, wait 1 minute! The throttle body gets electricity and has the chance of self-learning by the electronic control unit (ECU). 2. Turn off the key, power off! 3. Turn on the key again and finally start the engine. If the ECU still does not accept the throttle body: 1. Shut down the power of the ECU and wait 1 minute. Turn on the power again! 2. Repeat these operations of self-learning which are mentioned above. (1, 2 & 3).2. CHECK THE FEMALE PLUG If the throttle body does not work after you started the engine, please check the female plug carefully. Try to connect the female plug with the part again and make sure that both sides match well.

I have disconnected the battery to try to reset the ECU then followed above procedures ....light still on. Next step is to take to garage try procure again and then use electronic gismo to see if we can turn light off. If not then only option is to send back to Febi.

SELF LEARNING: If the throttle body is installed in the vehicle, do not start the engine immediately! The first operation should be: 1. Turn on the key, wait 1 minute! The throttle body gets electricity and has the chance of self-learning by the electronic control unit (ECU). 2. Turn off the key, power off! 3. Turn on the key again and finally start the engine. If the ECU still does not accept the throttle body: 1. Shut down the power of the ECU and wait 1 minute. Turn on the power again! 2. Repeat these operations of self-learning which are mentioned above. (1, 2 & 3).2. CHECK THE FEMALE PLUG If the throttle body does not work after you started the engine, please check the female plug carefully. Try to connect the female plug with the part again and make sure that both sides match well.

I have disconnected the battery to try to reset the ECU then followed above procedures ....light still on. Next step is to take to garage try procure again and then use electronic gismo to see if we can turn light off. If not then only option is to send back to Febi.

LandyAndy

Member

Is the TB working at all?

Easiest way to tell is start engine having the air intake supply off, and as soon as you turn the engine off it should close to 5%ish stay that way for about 1 min then open.

The test is an easy one as it isn’t relying on the egr system. And should do it every time you turn your engine off to stop judder and give smooth shut down.

Easiest way to tell is start engine having the air intake supply off, and as soon as you turn the engine off it should close to 5%ish stay that way for about 1 min then open.

The test is an easy one as it isn’t relying on the egr system. And should do it every time you turn your engine off to stop judder and give smooth shut down.

Hi did you get to the bottom of this fault ? Mine is doing the same it started when ticking over and stuck in a queue, erratic idling so stopped and started again but wouldn’t rev stopped again and left for a minute and tried stating again after a short time it started with eml on, it was still driving perfect with plenty power just took a few turns to start

It came up with tb fault so I bought a new one and it was flat and no power (thought it was faulty) and sent it back, bought a pierburg tb still flat no power bought adapter cable which seemed better but no boost, got sick and left it

Then I needed to move it and after about 100 yards I thought this is going well and was back to full power but eml is still on, so it sat for a couple of months started it and it’s back to no boost again

All the wiring has been checked from ECU and seems fine

It’s a Fiat Ducato 2007 3lt 160 multi jet

ANY HELP WOULD BE GREATLY APPRECIATED

It came up with tb fault so I bought a new one and it was flat and no power (thought it was faulty) and sent it back, bought a pierburg tb still flat no power bought adapter cable which seemed better but no boost, got sick and left it

Then I needed to move it and after about 100 yards I thought this is going well and was back to full power but eml is still on, so it sat for a couple of months started it and it’s back to no boost again

All the wiring has been checked from ECU and seems fine

It’s a Fiat Ducato 2007 3lt 160 multi jet

ANY HELP WOULD BE GREATLY APPRECIATED