The front end geometry has serious issues.

Front tyres hae worn down to < 3mm from new, within 15,000 kms. But even wear ?

The springs have the usual sag with only 750 mm measured to the wheel arch.

There is also the typical violent crash on the bump stops when any road bump or pot hole is crossed

I have tried 3 different suspension shops to get the allignment check and reset, but without luck since there is excess negative camber ( which cannot be adjusted) and none of the shops will do anything until i get the camber fixed.

My own crude but repeatable camber measurement suggests 10-15 deg negative on the driver side, and much more , 15-20deg on the passenger ( left) side. .??

At the same time there is at leas 15+ mm toe in !

Whilst this is a high milage (240k, kms) ex rental, its service records suggest new struts, ball joints, etc were fitted at 220k kms, and they do look recent.

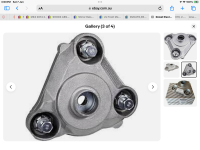

What could be causing this excess negative camber ? …struts not installed correctly

A plan on the increased height Kings springs, but need to understand what else may need replacing

Sugesstions on good mechanics in southern NSW also welcome !

Front tyres hae worn down to < 3mm from new, within 15,000 kms. But even wear ?

The springs have the usual sag with only 750 mm measured to the wheel arch.

There is also the typical violent crash on the bump stops when any road bump or pot hole is crossed

I have tried 3 different suspension shops to get the allignment check and reset, but without luck since there is excess negative camber ( which cannot be adjusted) and none of the shops will do anything until i get the camber fixed.

My own crude but repeatable camber measurement suggests 10-15 deg negative on the driver side, and much more , 15-20deg on the passenger ( left) side. .??

At the same time there is at leas 15+ mm toe in !

Whilst this is a high milage (240k, kms) ex rental, its service records suggest new struts, ball joints, etc were fitted at 220k kms, and they do look recent.

What could be causing this excess negative camber ? …struts not installed correctly

A plan on the increased height Kings springs, but need to understand what else may need replacing

Sugesstions on good mechanics in southern NSW also welcome !

- Model

- Ducato 150, 2.3 Td campervan

- Year

- 2019

- Mileage

- 206