Elmo1954

New member

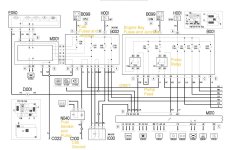

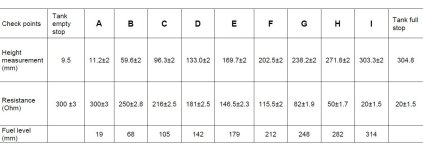

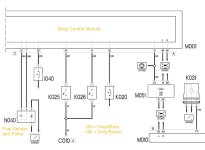

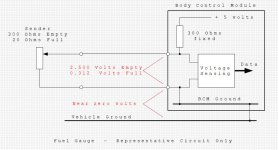

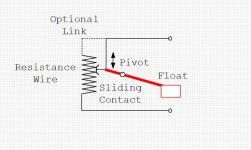

I am a newbie to the Forum. I have a FIAT Ducato, 2007, with 2.2 Diesel Installed. I got this with quite a few electrical problems, I have found available wiring diagrams difficult to obtain, those I have found are often unreadable. I have now fixed all problems (Rear Lights, Wipers, Heater Blower, and Horn) except 1, the Fuel Gauge. I have the connector that has 4 wires, a thick Grey one, a thick purple/black, a thin Grey/Brown (or dark Red), and a thin Grey/Black. The only drawing I can find shows that PIN 4 (thick Grey) should be Motor Pump Power Supply, and on testing. this wire is live with the Ignition on. My small drawing also states that PIN 1 (thin Grey/Brown) is Fuel Level Sensor Power Supply, however, this wire is NOT live with the Ignition on... Q: should it be? The thick Purple/Black, and the thin Grey/Black are Ground wires respectively.

With no diagram that simply says 'this wire should be live and comes via 'X' fuse or wherever', I am at a loss... in my much younger days you took off the unit's connector and put it to earth, if the gauge moved, the sensor/resistor was gone, that was easy lol.

I would be really appreciative of any advice, especially if someone can point me to an 'idiots guide' wiring diagram, or a link. I have tried looking in the Workshop Manual and the Trainers Guide Part 1 for the diagrams but no luck there, searching the Peugeot and Citroen diagrams seem equally as illusive?

Many thanks in anticipation...

Paul

With no diagram that simply says 'this wire should be live and comes via 'X' fuse or wherever', I am at a loss... in my much younger days you took off the unit's connector and put it to earth, if the gauge moved, the sensor/resistor was gone, that was easy lol.

I would be really appreciative of any advice, especially if someone can point me to an 'idiots guide' wiring diagram, or a link. I have tried looking in the Workshop Manual and the Trainers Guide Part 1 for the diagrams but no luck there, searching the Peugeot and Citroen diagrams seem equally as illusive?

Many thanks in anticipation...

Paul