lukekazi

New member

Hello,

I have a 1999 MK2 Punto Sporting, im looking to bypass the AC Compressor.

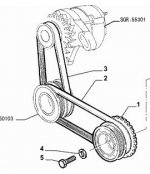

Unlike the later MK2 the Alternator is mounted on the top beside the intake manifold & the AC is on the bottom. It runs two separate belts one from alternator to AC & the AC to Crank. (Similar to the Pic but the AC to Crank 'belt 2' is on the Inner Pulley on mine)

The Outer Crank pulley looks like it lines up with the Alternator but I have no idea what size belt it would take etc....

I'm wondering if anyone have any ideas or done anything similar to this?

FYI sorry about the unclear picture didnt have much time so just took a quick snap

I have a 1999 MK2 Punto Sporting, im looking to bypass the AC Compressor.

Unlike the later MK2 the Alternator is mounted on the top beside the intake manifold & the AC is on the bottom. It runs two separate belts one from alternator to AC & the AC to Crank. (Similar to the Pic but the AC to Crank 'belt 2' is on the Inner Pulley on mine)

The Outer Crank pulley looks like it lines up with the Alternator but I have no idea what size belt it would take etc....

I'm wondering if anyone have any ideas or done anything similar to this?

FYI sorry about the unclear picture didnt have much time so just took a quick snap