I've been reading various threads about fitting aftermarket roof rails to the dobbie, but can't find anything related to the hi-roof version.

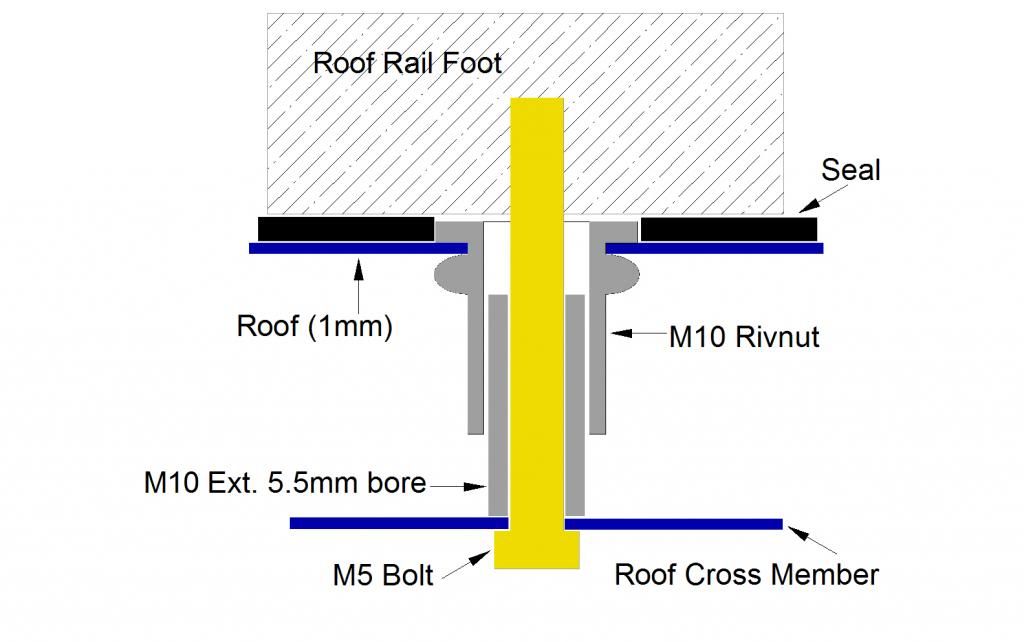

On this model the roof will have to be drilled in order to fit roof rails, as on the top of the roof four small recessed areas for fitting the rails are present but there are no holes.

I am aware of at least one forum member's mod to fit roof rails to the hi-roof model, so I'd appreciate any pointer and comments to the right direction!

Thanks in advance!

On this model the roof will have to be drilled in order to fit roof rails, as on the top of the roof four small recessed areas for fitting the rails are present but there are no holes.

I am aware of at least one forum member's mod to fit roof rails to the hi-roof model, so I'd appreciate any pointer and comments to the right direction!

Thanks in advance!