Okay , so the little lady was angry after a few months of neglect. Had to have the gas tank welded and POR-10 'd. So in my rush to make her happy again I failed to take note of the fuel line placement.

I had pulled all the fuel lines(from the tank as well as the dual DCNF's) to get the tank out (figured I would replace all the fuel lines and filter again).

However , I have forgotten where the two vent tube lines in the tank go.......

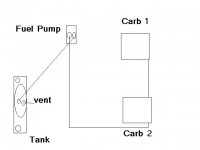

Attached is a rough (very rough) image of what i think it should be.

However , when all is piped up as it shpould be(i think) , that leaves me the two vent tubes on the tank.

Where do they go??

Feel like such a git but can't recall for the life of me.....

Please help!

I had pulled all the fuel lines(from the tank as well as the dual DCNF's) to get the tank out (figured I would replace all the fuel lines and filter again).

However , I have forgotten where the two vent tube lines in the tank go.......

Attached is a rough (very rough) image of what i think it should be.

However , when all is piped up as it shpould be(i think) , that leaves me the two vent tubes on the tank.

Where do they go??

Feel like such a git but can't recall for the life of me.....

Please help!