Sorry to ask a question on my first post.

I have an old, but low mileage 1.4 Tipo that we use as an emergency car cos we live out in the sticks.

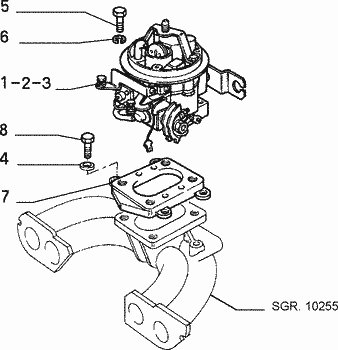

While giving it some checks today, I found that the carb (Weber TLDE) has literally come adrift of it's rubber block base and is basically floating free, with only the filter holding it down.

and is basically floating free, with only the filter holding it down.

I've been a mechanic for about a million years, but specialised in another make and have never seen anything similar before.

There don't appear to be any other mounting bolts apart from the ones that fix it to the manifold.

Does anyone know of a fix for this problem, or does it mean a carb exchange?

I'd be grateful for any help,

Thanks.

I have an old, but low mileage 1.4 Tipo that we use as an emergency car cos we live out in the sticks.

While giving it some checks today, I found that the carb (Weber TLDE) has literally come adrift of it's rubber block base

I've been a mechanic for about a million years, but specialised in another make and have never seen anything similar before.

There don't appear to be any other mounting bolts apart from the ones that fix it to the manifold.

Does anyone know of a fix for this problem, or does it mean a carb exchange?

I'd be grateful for any help,

Thanks.