nzbobc

New member

Well, being newbies and low on the learning curve, we're learning (sometimes the hard way) about the nuances of these cars. This time, we snapped one of the axles but letting out the clutch too quick. Looking at it closely, it had been snapped earlier in its life and had been welded back together..

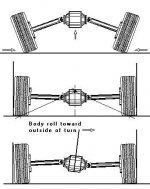

I've been reading online and in Haynes about axles and replacing them and felt good to go until I looked closely at the axles: They're different from everything I've seen/read. Ours have universal joints in them. Each axle appears shorter than what's shown elsewhere. Each axle connects to a universal joint, then to a shorter axle, which connects to the wheel hub.

So, kind folks, what can you tell me about these? This 500 has the 650cc motor and wheels off of a 126. I don't know if the transmission/differential is from a 500 or 126.

I'm seeing where I can buy the beefier (i.e., thicker) axles to handle the torque of the bigger motor but here's where I'm scratching my head:

Any thoughts/knowledge on axles with differentials?

Thanks,

-bob

I've been reading online and in Haynes about axles and replacing them and felt good to go until I looked closely at the axles: They're different from everything I've seen/read. Ours have universal joints in them. Each axle appears shorter than what's shown elsewhere. Each axle connects to a universal joint, then to a shorter axle, which connects to the wheel hub.

So, kind folks, what can you tell me about these? This 500 has the 650cc motor and wheels off of a 126. I don't know if the transmission/differential is from a 500 or 126.

I'm seeing where I can buy the beefier (i.e., thicker) axles to handle the torque of the bigger motor but here's where I'm scratching my head:

- It looks like I can buy these replacement axles which means I'd toss out the universal joints and the axles on both sides of the joint.

- But, do I need to replace the hubs? Are they the same/different?

- I'm worried that the angle of the new axles leaving the differential will be different and will muck up the meshing and/or bearing preload (I'm getting this from reading the Hayne's manual-Chapter 6-Transmission-Sections 7 and 8- Restoration of the Final Drive and Meshing the Crown Wheel and Pinion)

Any thoughts/knowledge on axles with differentials?

Thanks,

-bob