Hi.

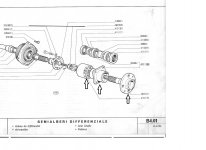

Replaced the rear wheel bearings during winter. The right wheel still have some "clonking". The 32mm is tight but still clonking? Tried to tighten it more but no differnce. Any ideas? I did not replaced the hub shaft. Any difference?

Many thanks.

Replaced the rear wheel bearings during winter. The right wheel still have some "clonking". The 32mm is tight but still clonking? Tried to tighten it more but no differnce. Any ideas? I did not replaced the hub shaft. Any difference?

Many thanks.

Last edited: