wackiejack

New member

- Joined

- Mar 13, 2018

- Messages

- 4

- Points

- 1

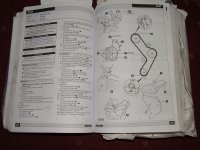

Hi All I have a fiat ducato 2.8 jtd 2005 does anybody know where the washers go on the bottom tensioner pully i know you have to put the lipped spacer washer on before the pully but does the cover go on before the outer spacer or does the outer spacer go on before the cover, then the cover, then the flat spring washer and 17mm nut, just a bit confused as at the moment there is a washer then the flat spring washer then the nut it appears that the alternator belt has been rubbing on the cover and the cover is distorted any help would be appreciated.