Hello everyone,

Unfortunately, the crankshaft case gasket on my engine (8140.47 116ps 2.5 tdi) is leaking. This means I'll have to remove the entire engine.

While I'm at it, I'd like to partially overhaul the engine as it's already done 300,000km.

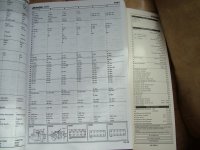

I couldn't find any workshop manuals or other data (tolerances, wear limits etc.) for this engine online, so I wanted to ask if anyone here might happen to have the relevant specifications and could share them with me?

Unfortunately, the crankshaft case gasket on my engine (8140.47 116ps 2.5 tdi) is leaking. This means I'll have to remove the entire engine.

While I'm at it, I'd like to partially overhaul the engine as it's already done 300,000km.

I couldn't find any workshop manuals or other data (tolerances, wear limits etc.) for this engine online, so I wanted to ask if anyone here might happen to have the relevant specifications and could share them with me?

- Model

- Ducato 230

- Year

- 1994

- Mileage

- 300000