Hi there

in The process of changing the diesel spill off pipe on our 2019 Fiat Ducato. The pieces across the injectors were pretty simple. The length that passes down under the engine however…… upon pulling that off the nipple has broken. Not only is is a nightmare to get to but I think the bracket and pipe fittings are one until.

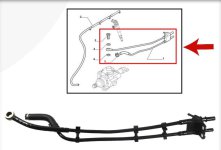

I’ve managed to get a picture or two and put a yellow arrow where I pulled the spill pipe from. Could anyone help with how I would start replacing the part that the spill pipe fits onto please?

Thanks

Duncan

in The process of changing the diesel spill off pipe on our 2019 Fiat Ducato. The pieces across the injectors were pretty simple. The length that passes down under the engine however…… upon pulling that off the nipple has broken. Not only is is a nightmare to get to but I think the bracket and pipe fittings are one until.

I’ve managed to get a picture or two and put a yellow arrow where I pulled the spill pipe from. Could anyone help with how I would start replacing the part that the spill pipe fits onto please?

Thanks

Duncan