Got there in the end!

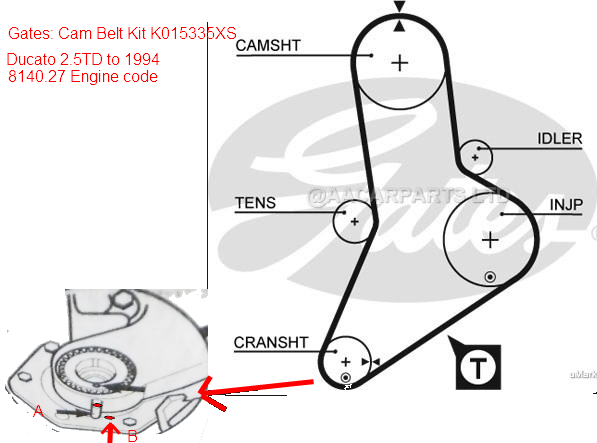

First to answer - nope both belts were 153, and same length within the bounds of possibility to measure.

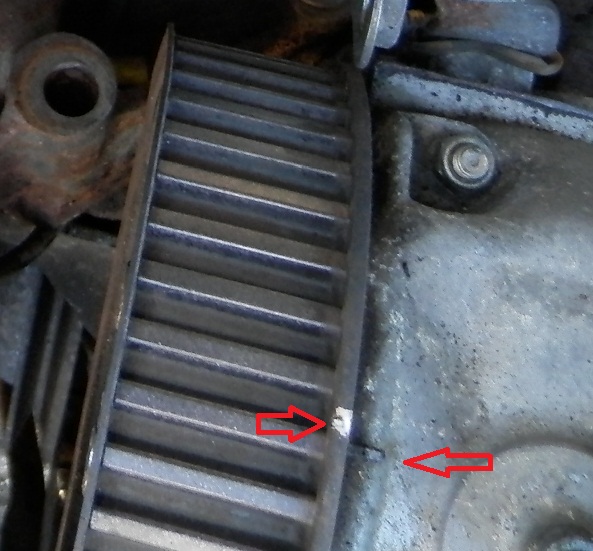

However when I used mark A, it now lines up, and the engine is back to her good old self.

So when you set you may find it challenging to line up until the belt has done a few miles (perhaps a tiny stretch / bedding in?)

0: Loosen all the injectors so you can turn the engine with relative ease.

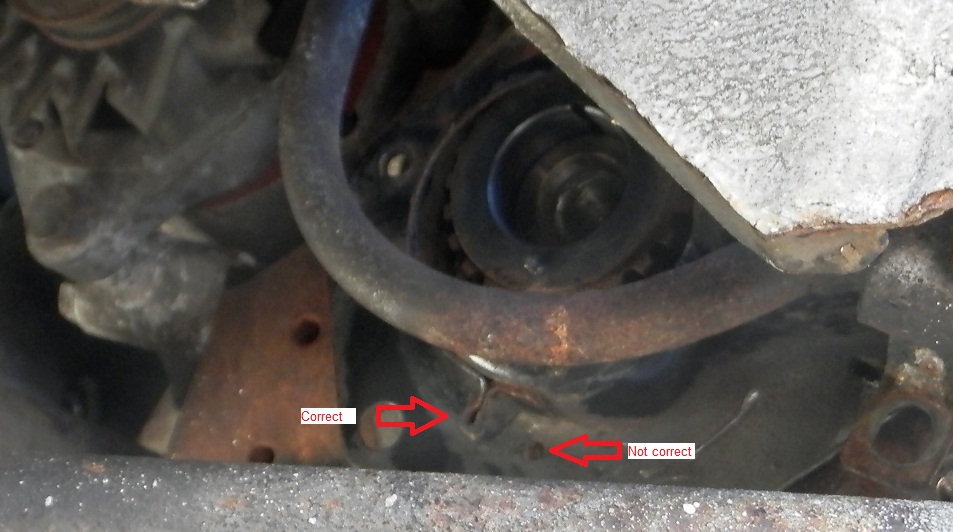

1: Line up the bottom pulley at A above, then put a block of wood on a jack and carefully jam the bottom pulley from turning.

2: Loosen the tensioner centre nut, and carefully lever back, locking in place using the centre nut again (lightly tightened enough to hold it from springing back)

3: Undo the idler, 3 bolts into the side of the block / head - not the centre bolt. This will give you room to rotate the pump and cam - hopping notches on the belt.

To set:

I started on the pump, keeping the belt between the pump and bottom pulley as taut as possible insert a 5/6 mm drill bit at 6 pm - the hole in pump pulley and pump body should align, the drill bit should hold it still, using all 8 of my hands (just joking) I then held the belt on the pump, whilst aligning the cam, this time keeping the tension between can pulley and tensioner as taught as possible (now the 8 hand bit)

Keeping both taught, you need to get the idler back into place.

Actually I pushed hard on the belt more or less where the idler pushes, which held both pump and cam in place, as I then negotiated the idler back into place.

With idler in place, double check the cam mark at 12 o'clock against the corresponding notch on the head / rocker top and the belt between pump and lower pulley is still taut.

Now release the tensioner, and rock the pump to remove the drill bit.

I gently levered the tensioner into the belt to make sure it held.

Drop the jack so you can turn the motor.

Now rotate the engine clockwise using the crank (lower pulley) bolt, this puts all the slack into where the tensioner can take it up. keep going until you have cycled back to the marks. Nip up the tensioner to make sure it doesn't move too easily.

Check your alignment, pump 6pm drill bit aligns, cam 12 o'clock and crank pulley mark at about 26/ 27 minutes to the hour - between 6 and 7 o'clock (mark A above).

I repeated the rotation 3 times, loosening the tensioner, rotating clockwise, nip up, check.

Finally torque up the the tensioner and make sure not to forget torquing the 3 bolts on the idler, and the injectors.

I fired up the engine with covers off, and with a great deal of care cleaned the rotating belt outside.

The motor started first time, and ran as smooth as a nut, where previously it started after 10 -15 revolutions and rattled like a transit!

So the conclusion it is possible to be 1 tooth out on the crank, as long as pump and cam are set the motor will run - like a transit!

New Gates belts are tough enough to make it look more correct to align the markings with Cam 12 O'Clock, Pump 6 O'Clock and Crank 6 O'clock - its that crank mark that is all critical, just past 6 pm.

I have a couple of photos from when I originally dismantled to change the belt. I'll try and post them!